Preparation method of lithium titanate negative electrode material and lithium titanate negative electrode material prepared by the method

A negative electrode material, lithium titanate technology, applied in the preparation of lithium titanate negative electrode material, lithium titanate negative electrode material field, can solve the problems of difficult uniform and effective coating, low reactivity of graphene sheets, etc., to achieve easy Industrial mass production, excellent electrochemical performance, and low hindrance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

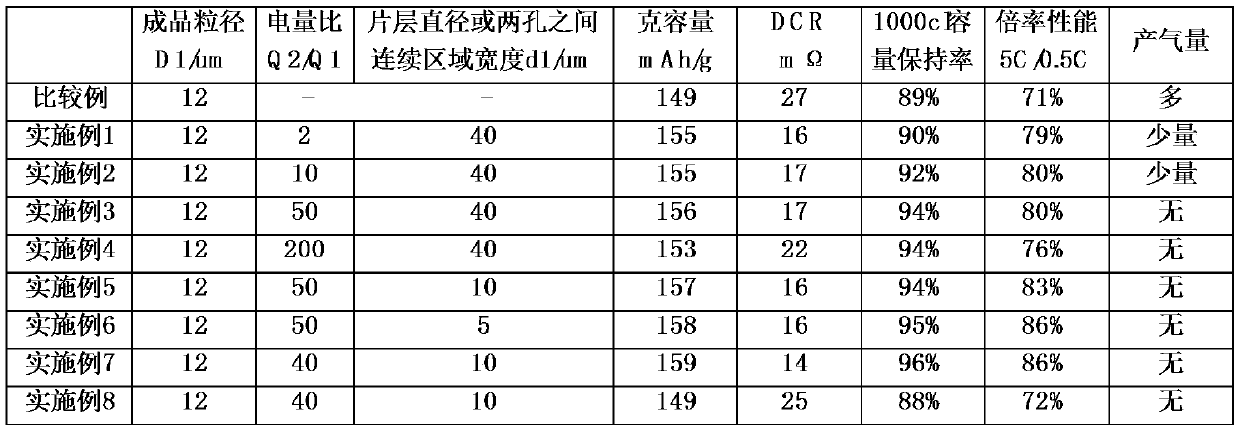

Examples

Embodiment 1

[0032] Embodiment 1, differs from comparative example in that this embodiment comprises the following steps:

[0033] Step 1, select the modified graphene (the graphene sheet contains hydroxyl, carboxyl, etc.) that the thickness of the sheet is 1nm and the plane size of the sheet is 40 μm, dissolve in water to obtain a solution, and then spray into the coating chamber, and make It has a negative charge of 10e;

[0034] Step 2. Preparation of core structure: select 100nm lithium titanate particles, mix them uniformly with conductive carbon black, and then pelletize to obtain a secondary particle core structure with a particle diameter of about 12 μm, and then spray it into the coating chamber, and make it With a positive charge of 20e;

[0035] Step 3, adjusting the airflow in the coating chamber, so that the particles in step 1 are evenly coated on the surface of the nuclear structure described in step 2 under the action of negative charges;

[0036]Step 4, water vapor is pa...

Embodiment 2

[0037] Embodiment 2 is different from Embodiment 1 in that this embodiment includes the following steps:

[0038] Step 1, select the modified graphene (the graphene sheet contains hydroxyl, carboxyl, etc.) that the thickness of the sheet is 1nm and the plane size of the sheet is 40 μm, dissolve in water to obtain a solution, and then spray into the coating chamber, and make It has a negative charge of 10e;

[0039] Step 2. Preparation of core structure: select 100nm lithium titanate particles, mix them uniformly with conductive agent components, and then spheroidize to obtain a secondary particle core structure with a particle diameter of about 12 μm, which is then sprayed into the coating chamber and made It has a positive charge of 100e;

[0040] Others are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0041] Embodiment 3 is different from Embodiment 1 in that this embodiment includes the following steps:

[0042] Step 1, select the modified graphene (the graphene sheet contains hydroxyl, carboxyl, etc.) that the thickness of the sheet is 1nm and the plane size of the sheet is 40 μm, dissolve in water to obtain a solution, and then spray into the coating chamber, and make It has a negative charge of 10e;

[0043] Step 2. Preparation of core structure: select 100nm lithium titanate particles, mix them uniformly with conductive agent components, and then spheroidize to obtain a secondary particle core structure with a particle diameter of about 12 μm, which is then sprayed into the coating chamber and made It has a positive charge of 500e;

[0044] Others are the same as in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com