Conductive rubber

A conductive rubber and the technology it contains are used in the rubber field to achieve the effects of easy vulcanization, good aging resistance and good fluidity.

Active Publication Date: 2012-02-29

芜湖禾田汽车工业有限公司

View PDF3 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The volume resistance of the conductive rubber filled with conductive carbon black can usually be kept at several thousand ohms. Since a single acetylene carbon black is used in the existing formula, its tensile strength can only reach 12Mpa, which is far from meeting the actual needs.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

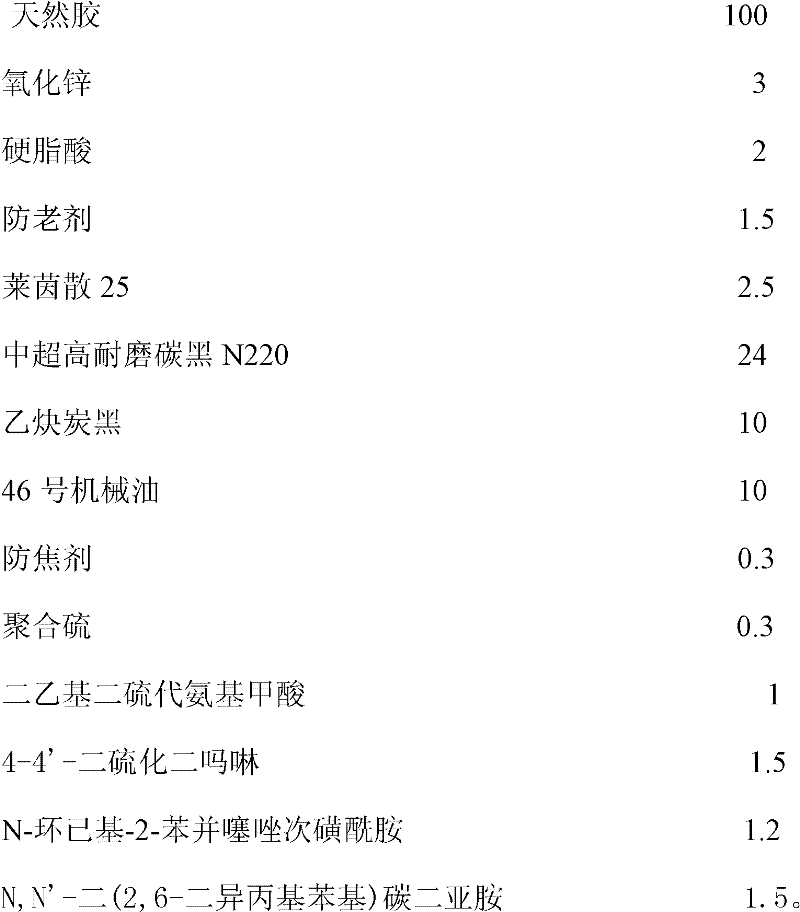

Embodiment 1

[0029] serial number

Embodiment 2

[0031] serial number

Embodiment 3

[0033] serial number

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Login to View More

Abstract

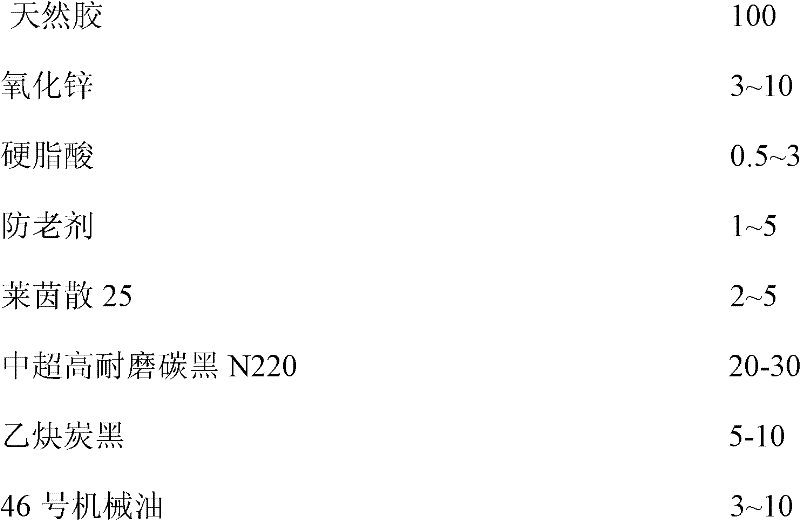

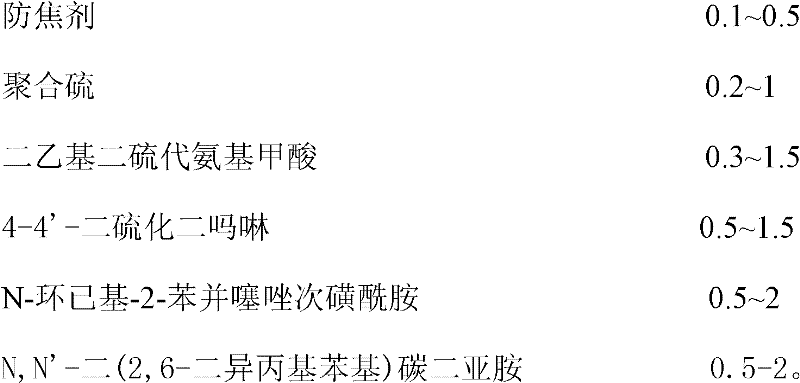

The invention discloses conductive rubber, which contains the following substances: natural rubber, zinc oxide, stearic acid, anti-aging agent, Rhine powder 25, middle and ultrahigh wear-resistance carbon black N220, acetylene carbon black, 46# machine oil, scorch retarder, polymeric sulphur, diethyldithiocarbamicacid, 4-4'-dithiodimorpholine, N-hexamethylene-2-benzothiazole sulfonamide, and N,N'- bis(2,6diisopropyl phenyl )carbodiimide. Compared with the prior art, the produced conductive rubber is an atrous rubber material, is excellent in gross rubber fluidity, is easy to be vulcanized and processed and is high in yield; the conductive rubber can be easily caked with metal; when 500V electricity is conducted by the rubber in a maximum parting position, resistance is not more than 500 kilo-ohms from the rubber to the metal; a tensile strength of the rubber is more than or equal to 25MPa; an elongation at break is more than or equal to 550 percent; and the rubber is excellent in ageing resistance and is suitable for the production of a conductive bush and a conductive rubber damping product.

Description

technical field [0001] This invention relates to rubber, and in particular to conductive rubber for use in bushings. Background technique [0002] Conductive rubber usually means that the volume resistance is within 9 times of 10 ohm centimeters. Since rubber is an excellent insulator, the volume resistance is greater than about 14 times of 10. The volume resistance of the conductive rubber filled with conductive carbon black can usually be kept at several thousand ohms. Since a single acetylene carbon black is used in the existing formula, its tensile strength can only reach 12Mpa, which is far from meeting the actual needs. Contents of the invention [0003] The technical problem to be solved by the present invention is to provide a conductive rubber with a tensile strength greater than 25Mpa. [0004] The technical scheme for solving the technical problems of the present invention is: a conductive rubber containing the following substances and parts by weight: [0005...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L7/00C08K13/02C08K3/22C08K3/04C08K5/39C08K5/47C08K5/29

Inventor 潘琦俊杨建辉

Owner 芜湖禾田汽车工业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com