Cable sheath material capable of resisting temperature of 150 DEG C and being used for bullet train with nominal voltage of 3,600 V, and preparation method thereof

A cable sheath material, rated voltage technology, applied in the field of cable materials, can solve the problem of unable to meet the needs of the motor car cable market, and achieve the effects of excellent high temperature resistance, excellent weather resistance, and excellent electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

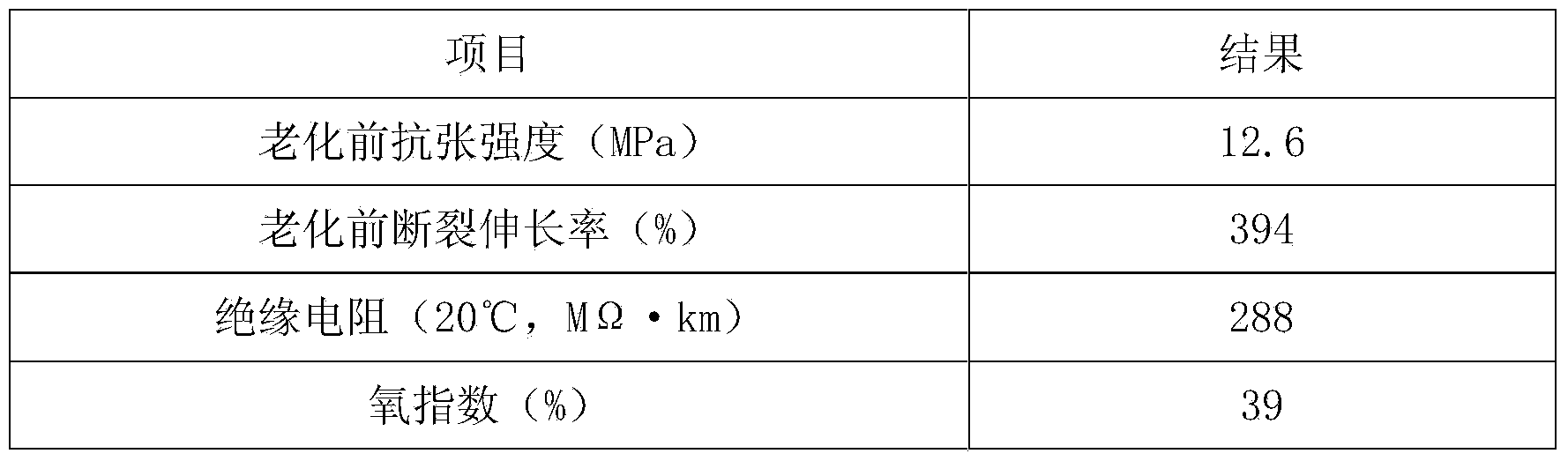

Examples

Embodiment Construction

[0012] A 150°C resistant cable sheathing material for a motor vehicle with a rated voltage of 3600V, which is made of the following raw materials in parts by weight: phenylene oxide silicone rubber 80, neoprene rubber 35, diisopropoxy diacetylacetonate titanium 4, diperoxide Cumene 3, tert-butyl peroxybenzoate 2, trimethylolpropane trimethacrylate 3, carbon black N66020, tris(2,3-dibromopropyl)isocyanurate 12, spindle oil 8. Hydrogenated rosin glyceride 10, boron carbide 7, glass powder 14, nano bismuth oxide 5, nano β molecular sieve 3, organic bentonite 18, meteorite powder 8, aluminum hypophosphite 12, nickel molybdate 4, modified stone powder 12, 4 ,4'-dithiodimorpholine 2.5, polycarbodiimide 1.5, styrenated phenol 2.5;

[0013] The preparation method of the modified stone powder is as follows: (1) Weigh coke, volcanic stone, and attapulgite at a weight ratio of 8:6:4, mix them uniformly, calcinate at 800°C for 1 hour, cool naturally to room temperature, pulverize, and sie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com