Battery cooling liquid resistant rubber tube material

A coolant and hose technology, which is applied in the field of battery-resistant coolant hose materials, can solve the problems of heat resistance, oil resistance, water resistance and aging resistance that cannot meet the needs of actual use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

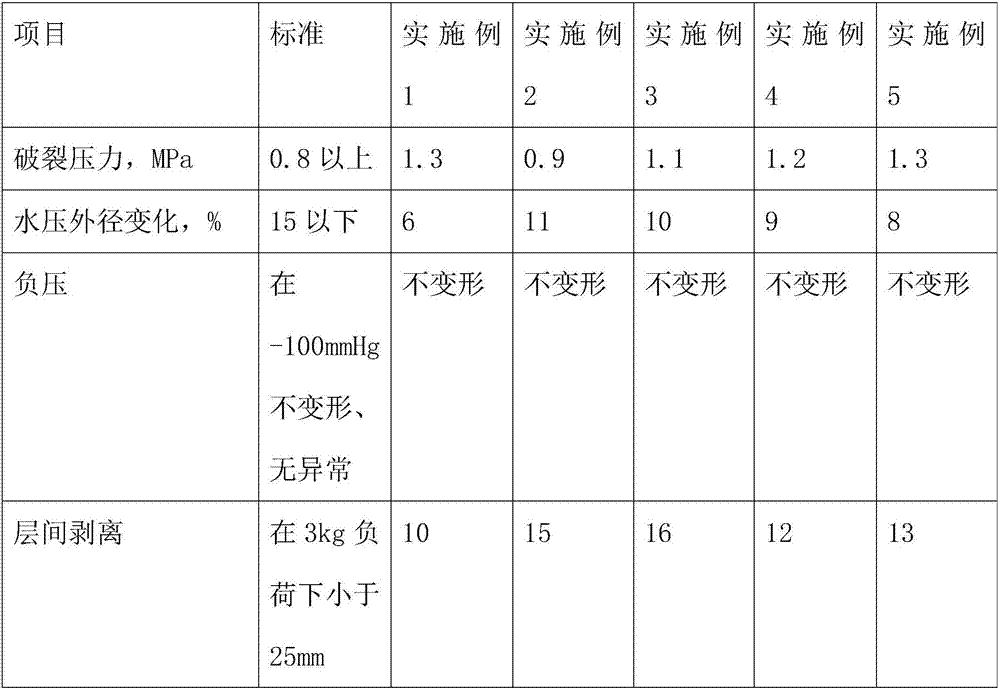

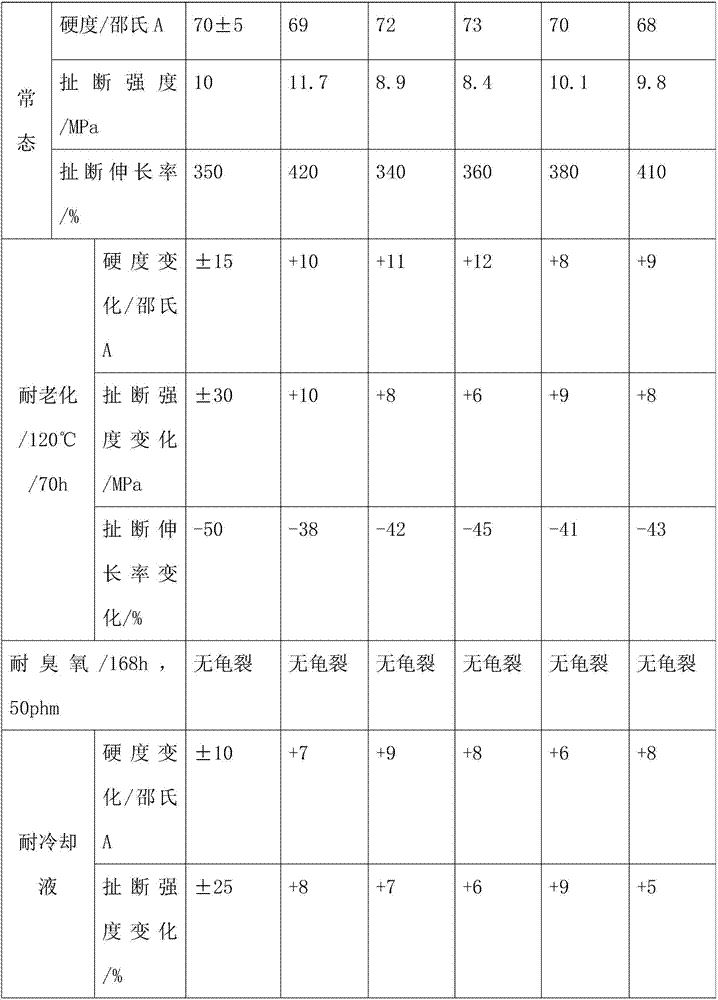

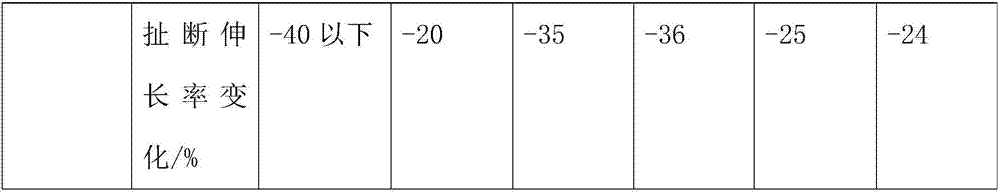

Examples

Embodiment 1

[0017] A kind of battery cooling fluid resistant hose material proposed by the present invention, its raw material comprises by weight: 70 parts of EPDM rubber, 40 parts of nitrile rubber, 15 parts of methyl vinyl silicone rubber, 10 parts of ternary nylon, 3 parts of foamed polystyrene, 4.5 parts of chlorinated polyethylene, 4 parts of zinc oxide, 2.5 parts of attapulgite, 4 parts of calcium sulfate whiskers, 2.5 parts of calcium carbonate, 3.5 parts of white carbon black, 4.5 parts of aluminum trichloride, 3 parts of maleic anhydride grafted ethylene-octene copolymer, 5 parts of silane coupling agent KH-560, 3.5 parts of 1,3-bis(tert-butylperoxydiisopropyl)benzene, triallyl isocyanide 4.5 parts of uric acid ester, 2.5 parts of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 3.5 parts of 2-mercaptobenzimidazole, 4 parts of dithiodimorpholine, 2- 3.5 parts of thiol imidazoline, 2.5 parts of accelerator CZ, 4.5 parts of accelerator BZ, 3.5 parts of N,N-dimethylformamide, 3 parts ...

Embodiment 2

[0023] A kind of rubber tube material resistant to battery cooling liquid proposed by the present invention, its raw material comprises by weight: 60 parts of EPDM rubber, 50 parts of nitrile rubber, 10 parts of methyl vinyl silicone rubber, 15 parts of ternary nylon, 1 part of foamed polystyrene, 6 parts of chlorinated polyethylene, 2 parts of zinc oxide, 4 parts of attapulgite, 3 parts of calcium sulfate whiskers, 4 parts of calcium carbonate, 2 parts of white carbon black, 6 parts of aluminum trichloride, 1 part of maleic anhydride grafted ethylene-octene copolymer, 8 parts of silane coupling agent KH-560, 2 parts of 1,3-bis(tert-butylperoxydiisopropyl)benzene, triallyl isocyanide 6 parts of uric acid ester, 1 part of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 5 parts of 2-mercaptobenzimidazole, 3 parts of dithiodimorpholine, 2- 5 parts of thiol imidazoline, 1 part of accelerator CZ, 6 parts of accelerator BZ, 2 parts of N,N-dimethylformamide, 5 parts of benzoyl peroxide...

Embodiment 3

[0029] A kind of rubber hose material resistant to battery cooling liquid proposed by the present invention, its raw material comprises by weight: 80 parts of EPDM rubber, 30 parts of nitrile rubber, 20 parts of methyl vinyl silicone rubber, 5 parts of ternary nylon, 5 parts of polystyrene foam, 3 parts of chlorinated polyethylene, 6 parts of zinc oxide, 1 part of attapulgite, 5 parts of calcium sulfate whiskers, 1 part of calcium carbonate, 5 parts of white carbon black, 3 parts of aluminum trichloride, 5 parts of maleic anhydride grafted ethylene-octene copolymer, 2 parts of silane coupling agent KH-560, 5 parts of 1,3-bis(tert-butylperoxydiisopropyl)benzene, triallyl isocyanide 3 parts of uric acid ester, 4 parts of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 2 parts of 2-mercaptobenzimidazole, 5 parts of dithiodimorpholine, 2- 2 parts of thiol imidazoline, 4 parts of accelerator CZ, 3 parts of accelerator BZ, 5 parts of N,N-dimethylformamide, 1 part of benzoyl peroxide, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com