Rubber composition for base rubber of radial giant engineering tire and preparation method thereof

A technology of rubber composition and engineering tires, which is applied in the field of rubber, can solve the problems of low thermal aging performance retention rate, affect the service life of tires, and serious vulcanization reversion, etc., and achieve high thermal aging performance retention rate, low loss factor, and use Effect of life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

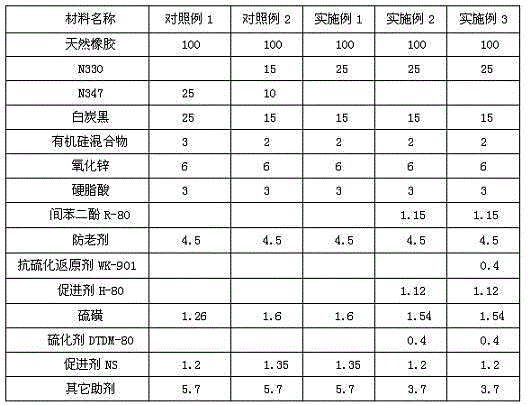

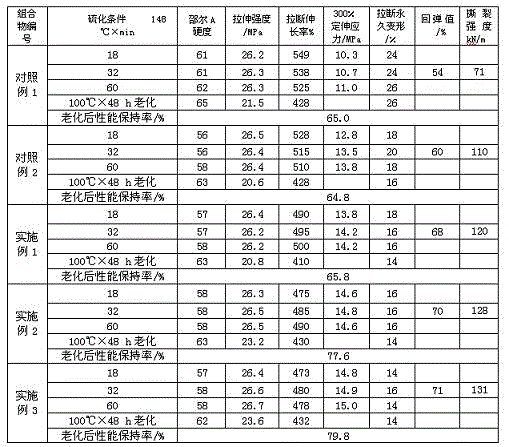

[0016] Below in conjunction with embodiment the present invention will be further described:

[0017] The invention adopts an all-natural rubber raw rubber system, the natural rubber molecular chain is supple, the raw rubber has high strength and high elasticity, and the obtained rubber composition has high strength, high elasticity, small deformation and low heat generation.

[0018] The invention adopts the reinforcing system of carbon black, white carbon black and organosilicon mixture, and the obtained rubber composition has high tear strength, low vulcanization reversion rate, good dynamic fatigue performance and low heat generation.

[0019] The present invention fills the giant OTR tire with a long vulcanization time with a certain weight portion of the anti-reversion agent, which can maintain the crosslinking density of the rubber composition and maintain good thermal stability during the long-term vulcanization process.

[0020] The present invention uses a reinforcin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com