Self-lubricating rubber leather diaphragm material and preparation method thereof

A self-lubricating and rubber-based technology, which is applied in the field of self-lubricating rubber film materials and its preparation, can solve the problems of not being able to meet the needs of consumers, not having high efficacy, and low production efficiency, so as to reduce the friction coefficient of the film surface and reduce the vulcanization molding time , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

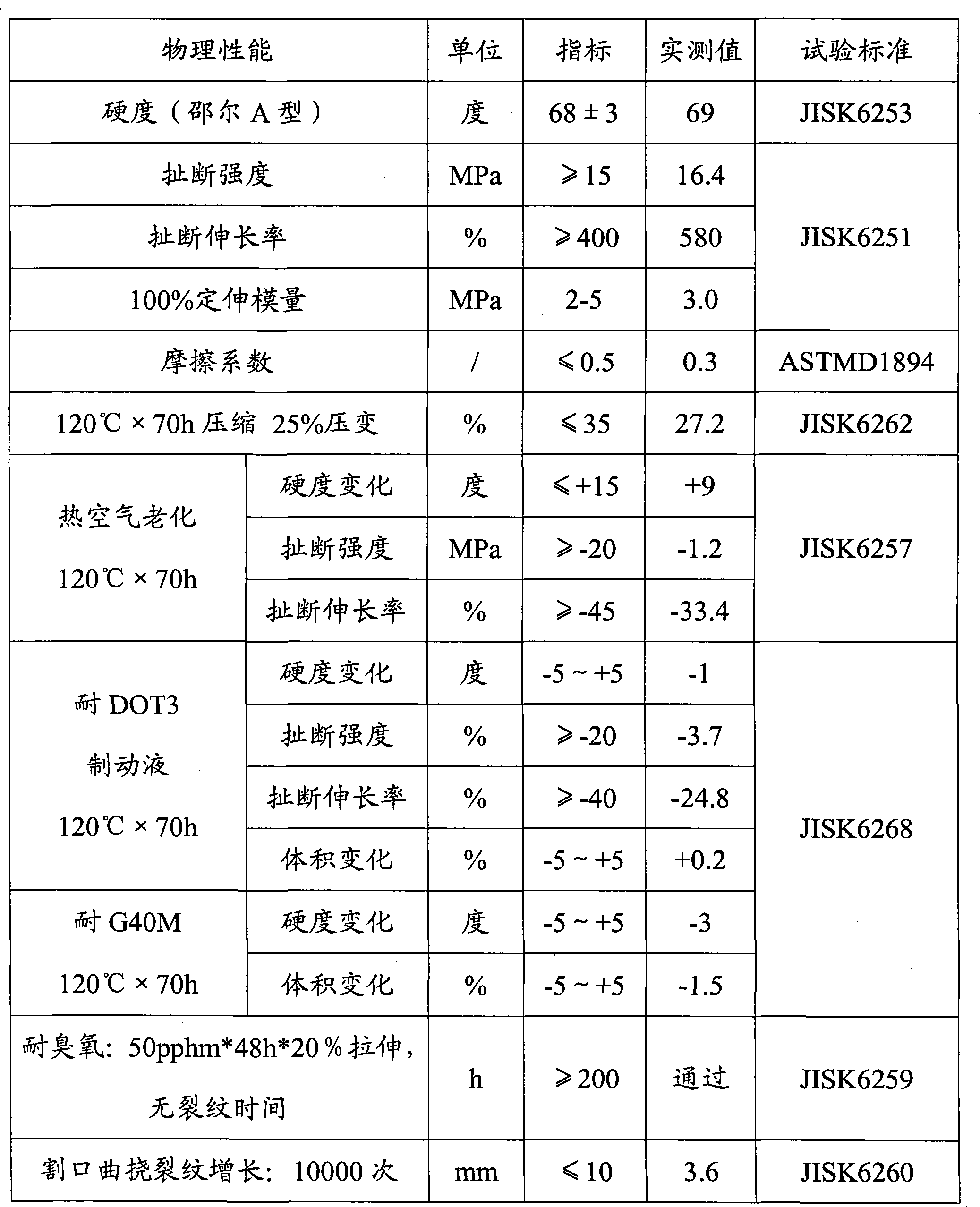

Examples

Embodiment 1

[0027] Prepare according to the following recipe:

[0028] Styrene-butadiene rubber (SBR1502): 80 parts, butadiene rubber (BR9000): 20 parts, zinc oxide: 3 parts, stearic acid: 1 part, 2,2,4-trimethyl-1,2-dihydroquinoline Phyloline polymer (antiaging agent RD): 1 part, N-isopropyl-N-phenyl-p-phenylenediamine (4010NA): 2 parts, oleic acid amide (TR121): 5 parts, polyethylene wax (AC617): 5 parts, high wear-resistant furnace black (N-330): 40 parts, fast extrusion furnace black (N-550): 30 parts, 4', 4-dithiodimorpholine (DTDM): 1 part, disulfide Tetramethylthiuram (TMTD): 1 part, N-cyclohexyl-2-benzothiazole sulfenamide (CZ): 3 parts.

[0029] One-stage mixing: put styrene-butadiene rubber and butadiene rubber in an internal mixer and knead for 50 seconds, so that the two rubbers can be mixed evenly to ensure product performance, and then add zinc oxide, stearic acid, 2,2,4-tri Mix methyl-1,2-dihydroquinoline polymer (anti-aging agent RD), N-isopropyl-N-phenyl-p-phenylenediam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com