EPDM (Ethylene-Propylene-Diene Monomer) white sponge strip for automobile air conditioner and preparation method of EPDM white sponge strip

A technology of automobile air conditioner, EPDMK4903, applied in the field of EPDM white sponge for automobile air conditioner and its preparation, can solve the problems of small pressure change and foaming density, high tensile strength, etc., and achieve small pressure change and foaming density, high tensile strength High tensile strength, good sound absorption and noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

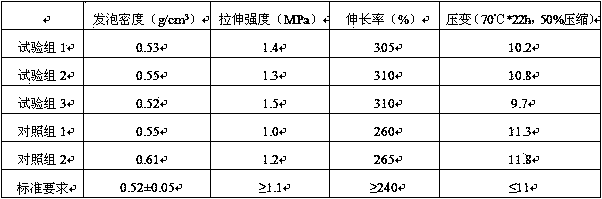

Examples

Embodiment 1

[0017] Embodiment 1 Preparation of EPDM white sponge strip for automobile air conditioner of the present invention (1)

[0018] Weigh each component by weight: 100 parts of EPDM K4903 raw rubber, 20 parts of white carbon black, 80 parts of silica, 70 parts of white oil, 15 parts of titanium dioxide, 5 parts of zinc oxide, 1 part of stearic acid, 2 parts of PEG4000 , 1 part of zinc stearate, 1 part of calcium stearate, 1 part of coupling agent, 0.01 part of carbon black N550, 3 parts of calcium oxide, 1 part of MBT-80, 1 part of ZDBC-80, 0.5 part of TDEC-75, AC-75 3 parts, OBSH 3 parts, DTDM 1 part, S-80 1 part.

[0019] Preparation process: EPDM K4903 raw rubber, white carbon black, silica, white oil, titanium dioxide, zinc oxide, stearic acid, PEG4000, zinc stearate, calcium stearate, coupling agent, carbon black N550, oxidation Calcium, MBT-80, ZDBC-80, TDEC-75, AC-75, OBSH, DTDM, S-80 are mixed to make a section of glue, the glue discharge temperature is 130-140°C, and th...

Embodiment 2

[0020] Embodiment 2 Preparation of EPDM white sponge strip for automobile air conditioner of the present invention (two)

[0021] Weigh each component by weight: 100 parts of EPDM K4903 raw rubber, 30 parts of white carbon black, 100 parts of silica, 90 parts of white oil, 20 parts of titanium dioxide, 8 parts of zinc oxide, 2 parts of stearic acid, 4 parts of PEG4000 , 1 part of zinc stearate, 2 parts of calcium stearate, 3 parts of coupling agent, 0.01 part of carbon black N550, 5 parts of calcium oxide, 2 parts of MBT-80, 2 parts of ZDBC-80, 0.8 part of TDEC-75, 5 copies of AC-75, 5 copies of OBSH, 2 copies of DTDM, 2 copies of S-80.

[0022] Preparation process: EPDM K4903 raw rubber, white carbon black, silica, white oil, titanium dioxide, zinc oxide, stearic acid, PEG4000, zinc stearate, calcium stearate, coupling agent, carbon black N550, oxidation Calcium, MBT-80, ZDBC-80, TDEC-75, AC-75, OBSH, DTDM, S-80 are mixed to make a section of glue, the glue discharge tempe...

Embodiment 3

[0023] Example 3 Preparation of EPDM white sponge strip for automobile air conditioner of the present invention (3)

[0024] Weigh each component by weight: 100 parts of EPDM K4903 raw rubber, 20 parts of white carbon black, 80 parts of silica, 90 parts of white oil, 20 parts of titanium dioxide, 5 parts of zinc oxide, 1 part of stearic acid, 4 parts of PEG4000 , 2 parts of zinc stearate, 1 part of calcium stearate, 1 part of coupling agent, 0.01 part of carbon black N550, 3 parts of calcium oxide, 2 parts of MBT-80, 2 parts of ZDBC-80, 0.5 part of TDEC-75, AC-75 3 parts, OBSH 5 parts, DTDM 2 parts, S-80 1 part.

[0025] Preparation process: EPDM K4903 raw rubber, white carbon black, silica, white oil, titanium dioxide, zinc oxide, stearic acid, PEG4000, zinc stearate, calcium stearate, coupling agent, carbon black N550, oxidation Calcium, MBT-80, ZDBC-80, TDEC-75, AC-75, OBSH, DTDM, S-80 are mixed to make a section of glue, the glue discharge temperature is 130-140°C, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com