Patents

Literature

30results about How to "Sound absorption and noise reduction effect is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

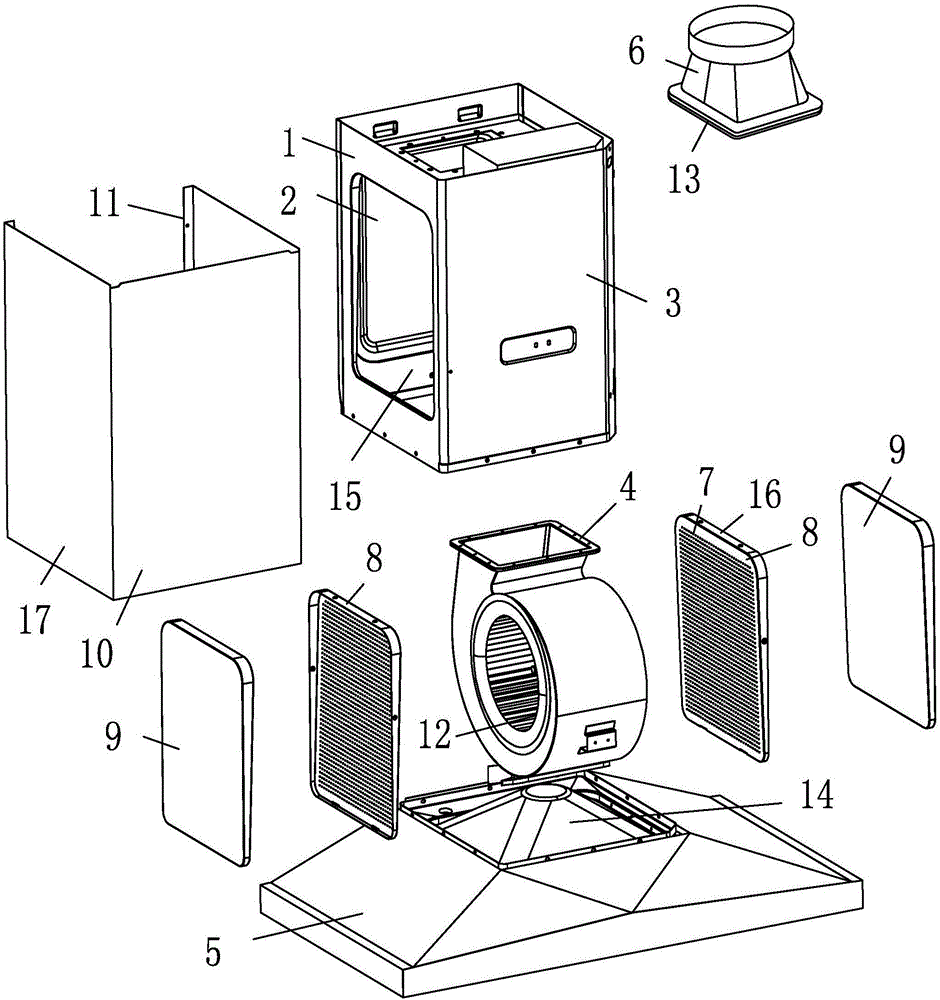

Low noise and large suction range hood

InactiveCN106439959AIncrease stiffnessEasy and stable installationDomestic stoves or rangesLighting and heating apparatusMicro perforated plateLow noise

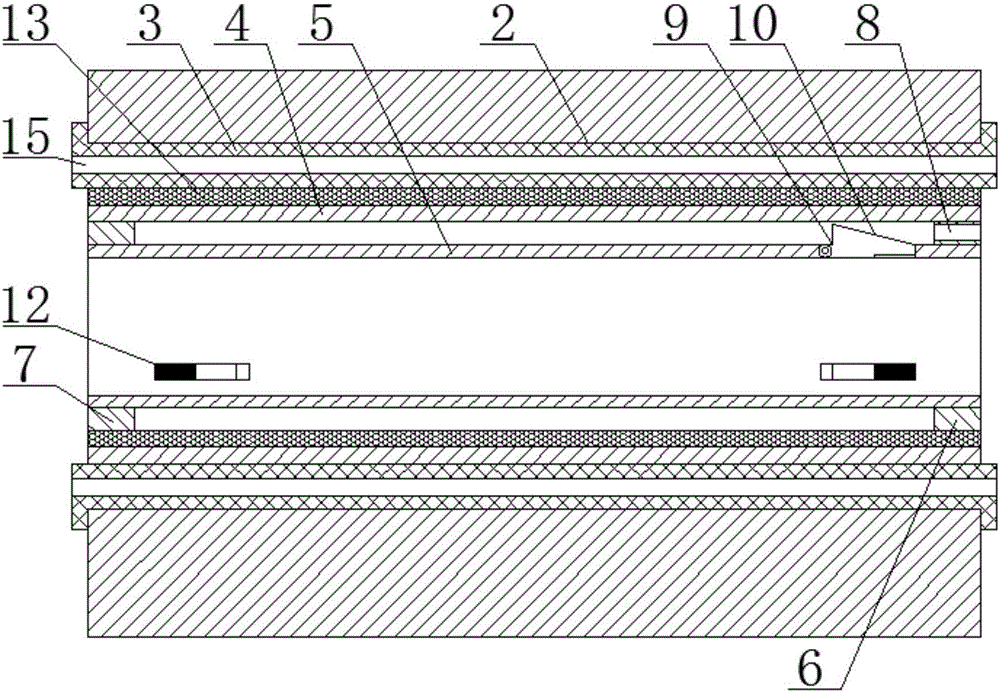

The invention relates to the field of kitchen appliances and aims at providing a low noise and large suction range hood. The low noise and large suction range hood comprises a main case provided with two inner side plates and a rear through hole located in the rear end, an air duct arranged in the main case, a smoke collecting hood arranged at the lower end of the main case, and a check valve arranged at the upper end of the main case. The low noise and large suction range hood further comprises two parallel micro perforated plates provided with silencing small hole sets, and two sound absorbing and noise lowering plates; the two opposite side ends of the air duct are each provided with an air inlet; the two micro perforated plates are opposite to the two air inlets one to one; and the two micro perforated plates correspond to the two inner side plates one to one and each press one sound absorbing and noise lowering plate to be connected with the inner side of the corresponding inner side plate. The low noise and large suction range hood has the large air volume and air pressure strong suction performance and is low in noise.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

High-water-permeability concrete water-permeable ground tiles

The invention discloses high-water-permeability concrete water-permeable ground tiles. The high-water-permeability concrete water-permeable ground tiles are prepared from the following raw materials in parts by weight: 120-150 parts of a main material, 2-10 parts of glutinous rice flour, 1-6 parts of gypsum, 1-2 parts of magnesium carbonate, 20-40 parts of regenerated rubber powder, 60-100 parts of blast furnace slag, 1-2 parts of aluminum powder, 6-10 parts of fly ash, 3-8 parts of sepiolite powder, 1-6 parts of mica powder, 4-10 parts of basalt fiber, 2-9 parts of heavy calcium carbonate, 1-4 parts of microcrystalline cellulose, 1-2 parts of polydimethylsiloxane, 1-2 parts of tartaric acid, 1-2 parts of a water-reducing agent, and 100-200 parts of water. A carbon nanotube composite is prepared by adopting a technology comprising the following steps of uniformly mixing urea, formaldehyde and water, adjusting the pH value of the system to 8.6-8.9, and carrying out heating with stirring; adding lecithin, carbon nanotubes and N,N-dimethyl-formamide, and carrying out uniform stirring; and then, adding polypropylene, and carrying out stirring so as to obtain the carbon nanotube composite.

Owner:蚌埠市宝运商品混凝土有限公司

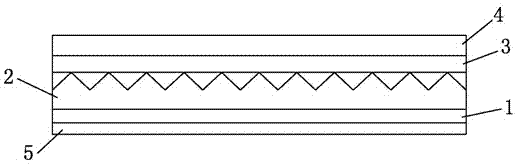

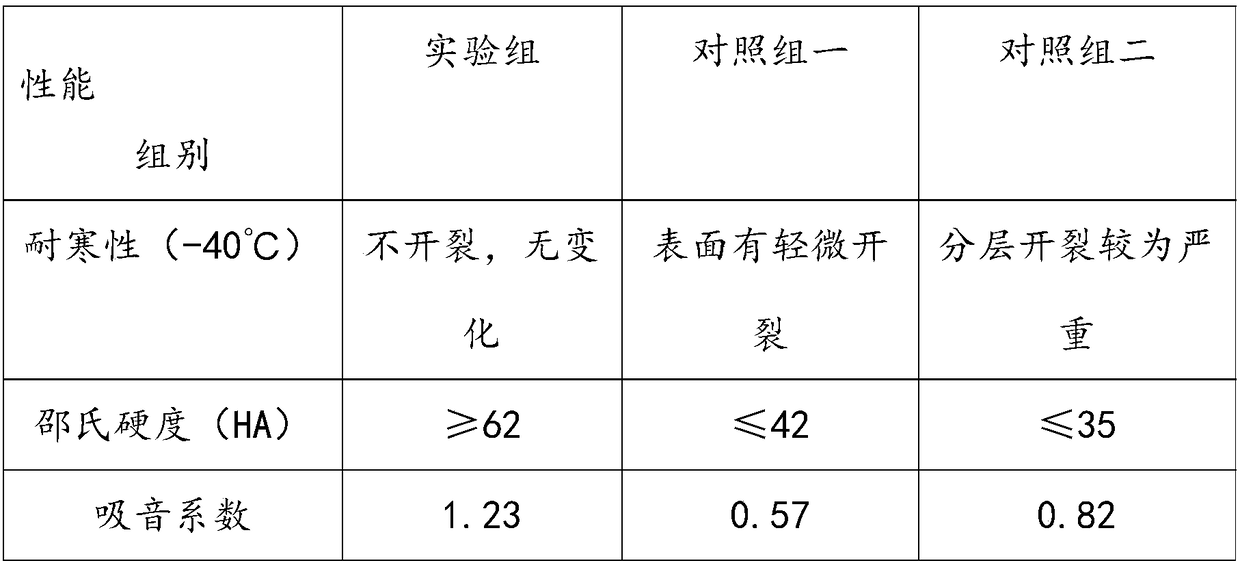

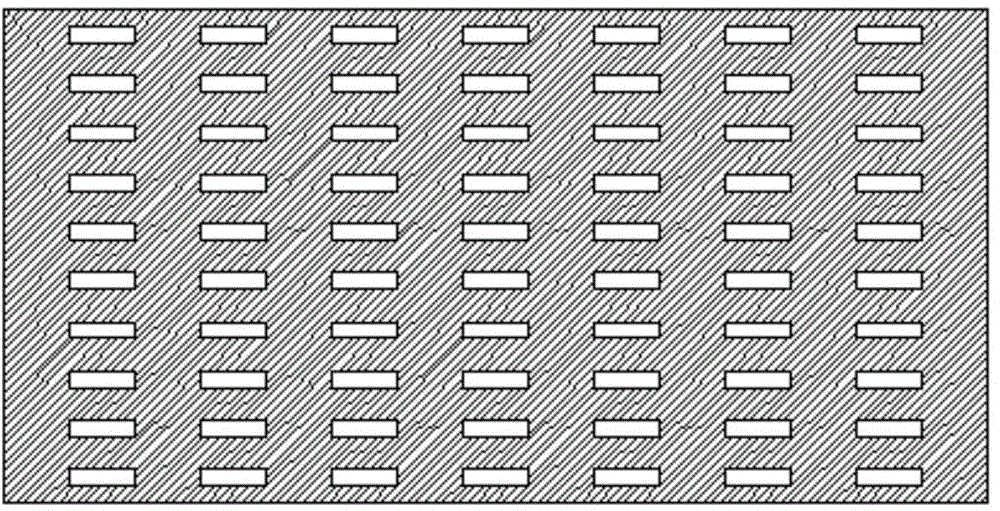

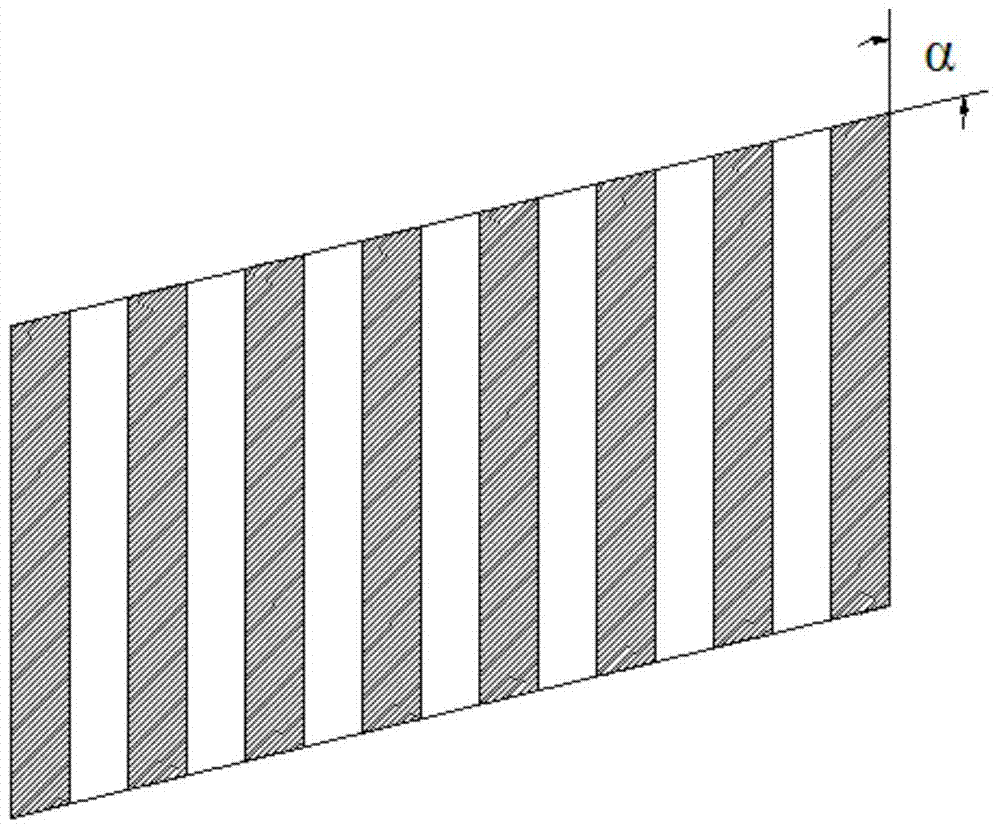

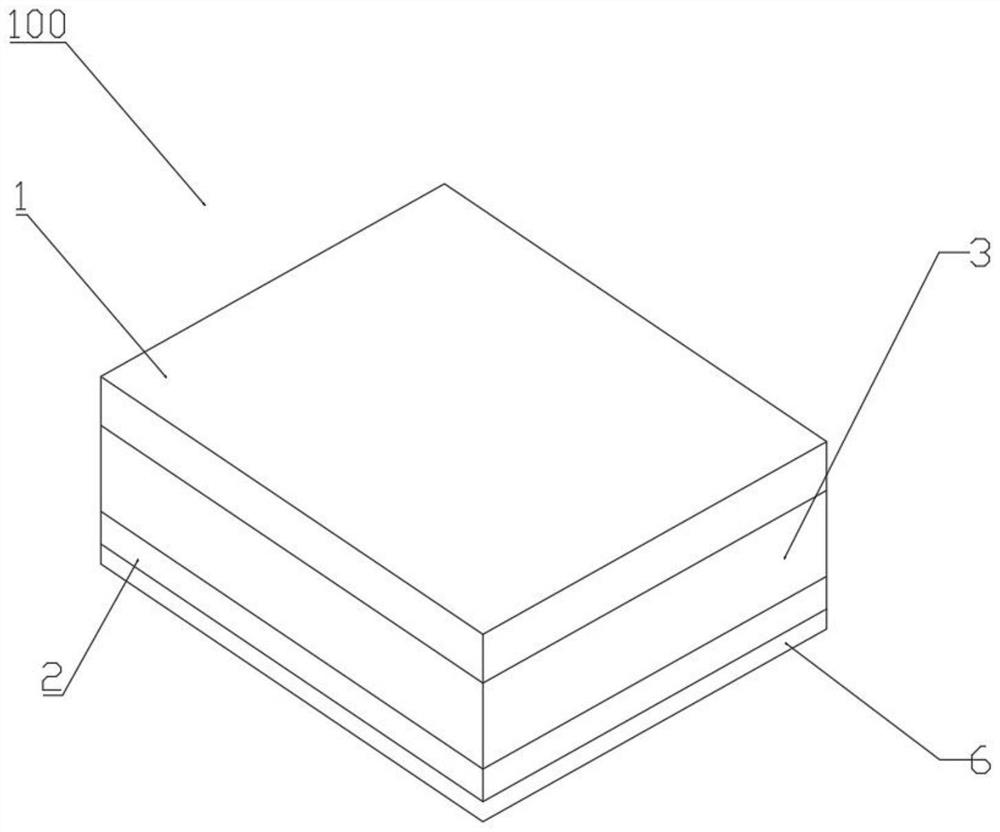

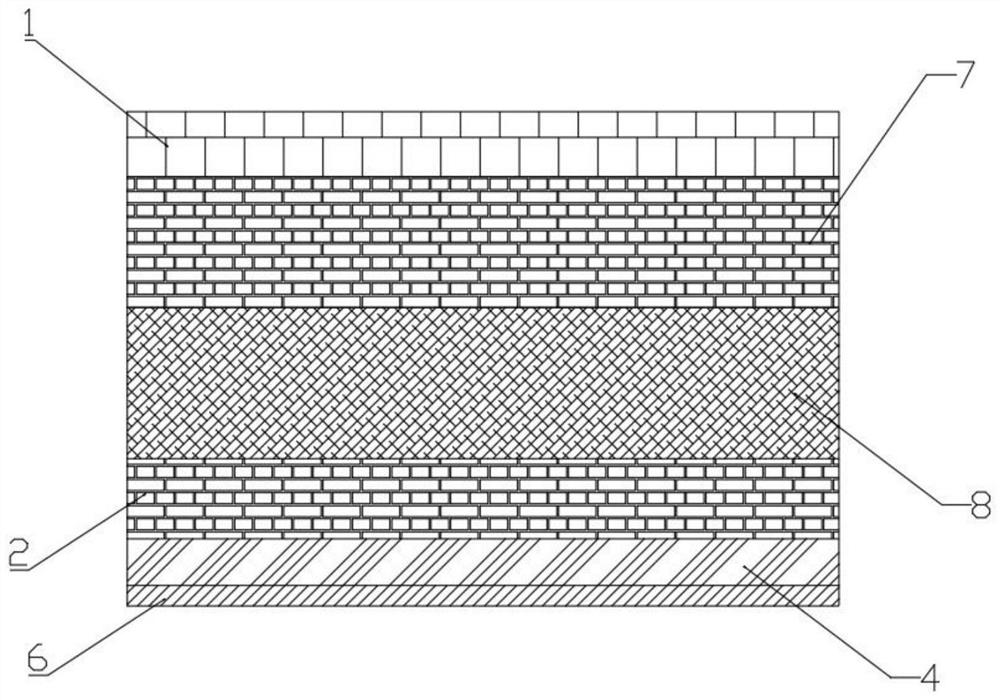

Silencing composite board used for automobile

InactiveCN104842893AIncrease sound-absorbing areaSound absorption and noise reduction effect is goodSynthetic resin layered productsVehicle componentsEngineeringNoise reduction

The invention discloses a silencing composite board used for an automobile. The silencing composite board comprises a sound insulation substrate, a sound absorption layer and a sound absorption panel layer are sequentially arranged on the surface of the sound insulation substrate from bottom to top, the surface of the sound absorption panel layer is coated with a fire-proof coating, the top face of the sound absorption layer is in a concave-convex saw tooth shape, and an adhesive coating is arranged on the bottom face of the sound insulation substrate. The silencing composite board is installed in an assembly gap of the automobile and has a good sound absorption and noise reduction effect; particularly, the top face of the sound absorption layer is in the concave-convex saw tooth shape, in this way, the sound absorption area of the sound absorption layer can be greatly increased, and the noise reduction effect is improved; meanwhile, the surface of the sound absorption panel layer is coated with the fire-proof coating, so that safety performance is improved; in addition, the adhesive coating is arranged on the bottom face of the sound insulation substrate, in this way, the silencing composite board can directly adhere to the automobile as long as a packaging film of the silencing composite board is disclosed, and installing is convenient.

Owner:左正晓

Sound absorption material and preparation method thereof

The invention discloses a sound-absorbing material, which comprises the following raw materials in parts by weight: 18-27 parts of sepiolite, 15-25 parts of modified starch, 13-28 parts of attapulgite clay, 7-10 parts of modified tree ash, 10-30 parts of ceramsite, 9-18 parts of calcined bauxite, 4-6 parts of nano wollastonite powder, 8-16 parts of styrene-acrylic emulsion, 5-12 parts of graphite powder, 5-15 parts of polypropylene fiber, stearin Calcium acid 2-3 parts, aluminum hydroxide 1-2 parts, foaming agent 2-3 parts, sodium polyphosphate 1.3-2.3 parts, polyacrylamide 3-5 parts, rare earth catalyst 1.5-2.5 parts. The sound-absorbing material has the advantages of low cost, low density, convenient use, high structural strength, good sound-absorbing and noise-reducing effects, excellent chemical stability, and is suitable for various occasions.

Owner:合肥慧林建材有限公司

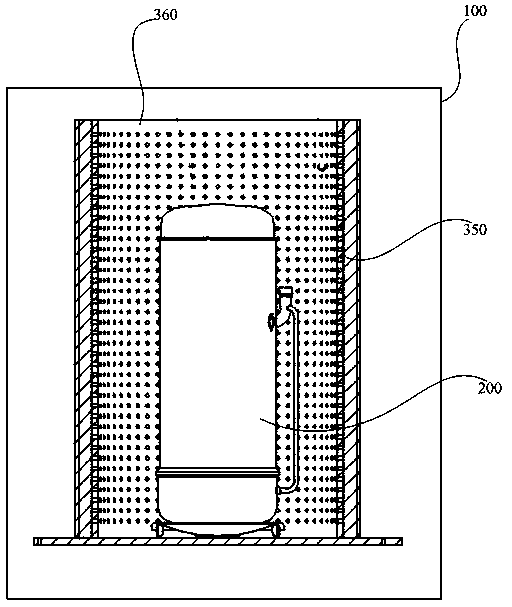

Refrigerating equipment

InactiveCN111238019AEnhance the effect of sound absorption and energy consumptionSound absorption and noise reduction effect is goodCompressorNoise suppressionMicro perforated plateNoise

The invention provides refrigerating equipment which comprises a shell, a compressor, a sound isolating cover and a viscoelastic film layer, wherein an accommodating space is formed in the shell; thecompressor is arranged in the shell; the sound isolating cover at least comprises a sound absorbing layer and micro perforation plates which are successively arranged from outside to inside, the soundabsorbing layer is provided with a plurality of first sound absorbing parts penetrating the sound absorbing layer, and at least one perforation plate is arranged and a plurality of second sound absorbing parts penetrating the micro perforation plate are arranged on the micro perforation plate; when the radiation noise frequency of the compressor reaches a first frequency, the viscoelastic film layer resonates to consume energy and drive air to fluctuate in a reciprocating manner between the first and second sound absorbing parts to rub to consume energy; when the radiation noise frequency ofthe compressor reaches a second frequency, an air column in the second sound absorbing part resonates, rubs with the second sound absorbing part to consume energy, and at least can drive the viscoelastic film layer in the second sound absorbing part to vibrate to consume energy an drive air in the first absorbing part to fluctuate to consume energy. The refrigerating equipment solves the problem that the refrigerating equipment in the prior art is poor in sound isolating effect to the compressor.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

Roots blower pipeline noise reduction device

InactiveCN103244464AReduce noise emissionsSound absorption and noise reduction effect is goodPump componentsPumpsInsulation layerHigh density

The invention discloses a Roots blower pipeline noise reduction device which comprises silencing box and an internal sound absorbing layer wrapped outside a pipeline. The internal sound absorbing layer is disposed in the silencing box. A cavity is formed between the inner wall of the silencing box and the sound absorbing layer. The silencing box, the cavity and the internal sound absorbing layer form a secondary silencing composite structure. The internal sound absorbing layer is three-layered and comprises a galvanized plate, high-density centrifugal glass cotton and low-density centrifugal glass cotton from outside to inside. The silencing box is four-layered and comprises a face protecting layer, a sound insulation layer, a sound absorbing layer and a inner plate form outside to inside. By the secondary silencing composite structure, the problem that inlet-outlet pipeline noise is high and radiation range is wide during operation of a Roots blower is solved, and noise pollution to environments is reduced effectively. The device is suitable for wide popularization in places with severe noise pollution.

Owner:SHANDONG ZHANGQIU BLOWER

High toughness concrete permeable floor tile

The invention discloses a high toughness concrete permeable floor tile. The high toughness concrete permeable floor tile is prepared from the following raw materials in parts by weight: 150 to 170 parts of aluminate cement, 40 to 50 parts of halloysite compound, 160 to 180 parts of a pore control agent, 4 to 6 parts of hydroxypropyl cellulose, 2 to 4 parts of polyoxypropylene glycerol ether, 2 to4 parts of citric acid, 2 to 4 parts of a water-reducing agent, 8 to 16 parts of quick lime, 4 to 8 parts of sodium silicate, 2 to 4 parts of magnesium carbonate and 160 to 240 parts of water. The halloysite compound is prepared by adopting the following technology: uniformly mixing urea, formaldehyde and water; adjusting a pH value of a system to 8.6 to 8.9 and raising the temperature for stirring; adding cocamidopropyl betaine, halloysite nanotube and N,N-dimethylformamide for uniform stirring and adding polystyrene for stirring to obtain the halloysite compound. The high toughness concretepermeable floor tile disclosed by the invention has the advantages of long service life, high water permeability, good toughness, easiness in construction, low possibility of fading and excellent durability.

Owner:蚌埠市宝运商品混凝土有限公司

Montmorillonite tailing ecological self-cleaning water permeable brick and manufacturing method thereof

InactiveCN105967605AImprove self-cleaning effectHigh compressive strengthSolid waste managementCeramicwarePorosityBrick

The invention discloses a montmorillonite tailing ecological self-cleaning water permeable brick. After a carbonized treatment, carbonized peanut shell is ground at room temperature; the pore surface adsorbs a photocatalytic material nanometer titania; and light irradiation is conducted to generate hydroxyl radical, super-oxygen ion free radical and H2O free radical which have strong capacity of oxidization and decomposition to directly oxidize various organic matter into inorganic micomolecules such as CO2 and H2O, etc. By applying the above product into a water permeable brick, the water permeable brick can degrade automobile exhaust and the like in the atmosphere. In addition, the water permeable brick also has strong adsorbability and excellent sound absorption and noise reduction effects. Modified sugar filter mud is used as a pore-forming agent, and montmorillonite and broken stone are used as aggregate. The water permeable brick prepared after high-temperature sintering of the materials has large porosity, excellent self-cleaning effect, high compressive strength, better wear resistance and obvious water permeable effect, is not easy to block, and is not easy for ponding in rainy days. By effective utilization of slags, the product has obvious social, economic and environmental benefits.

Owner:安徽徽明建设集团有限公司

Colored high-titanium heavy slag self-cleaning water permeable brick and manufacturing method thereof

InactiveCN105967637AHigh porosityGood water permeabilityCeramic materials productionCeramicwarePorosityBrick

The invention discloses a colored high-titanium heavy slag self-cleaning water permeable brick. After carbonization treatment, carbonized pea stalk is ground at room temperature; the pore surface adsorbs a photocatalytic material nanometer titania; and light irradiation is conducted to generate hydroxyl radical, super-oxygen ion free radical and H2O free radical which have strong capacity of oxidization and decomposition to directly oxidize various organic matter into inorganic micomolecules such as CO2 and H2O, etc. By applying the above product into a water permeable brick, the obtained water permeable brick can degrade automobile exhaust and the like in the atmosphere. In addition, the water permeable brick has strong adsorbability and excellent sound-absorption and noise-reduction effects. According to the invention, modified sugar filter mud is used as a pore-forming agent, and high-titanium heavy slag, slag from a power plant and hemihydrate gypsum are used as aggregates. The water permeable brick prepared after high-temperature sintering of the materials has large porosity, excellent self-cleaning effect, good water permeability and high compressive strength. In addition, cost of raw materials is low, and environmental pollution caused by blast furnace slag is also avoided. The water permeable brick can be paved on plazas or sidewalk.

Owner:安徽徽明建设集团有限公司

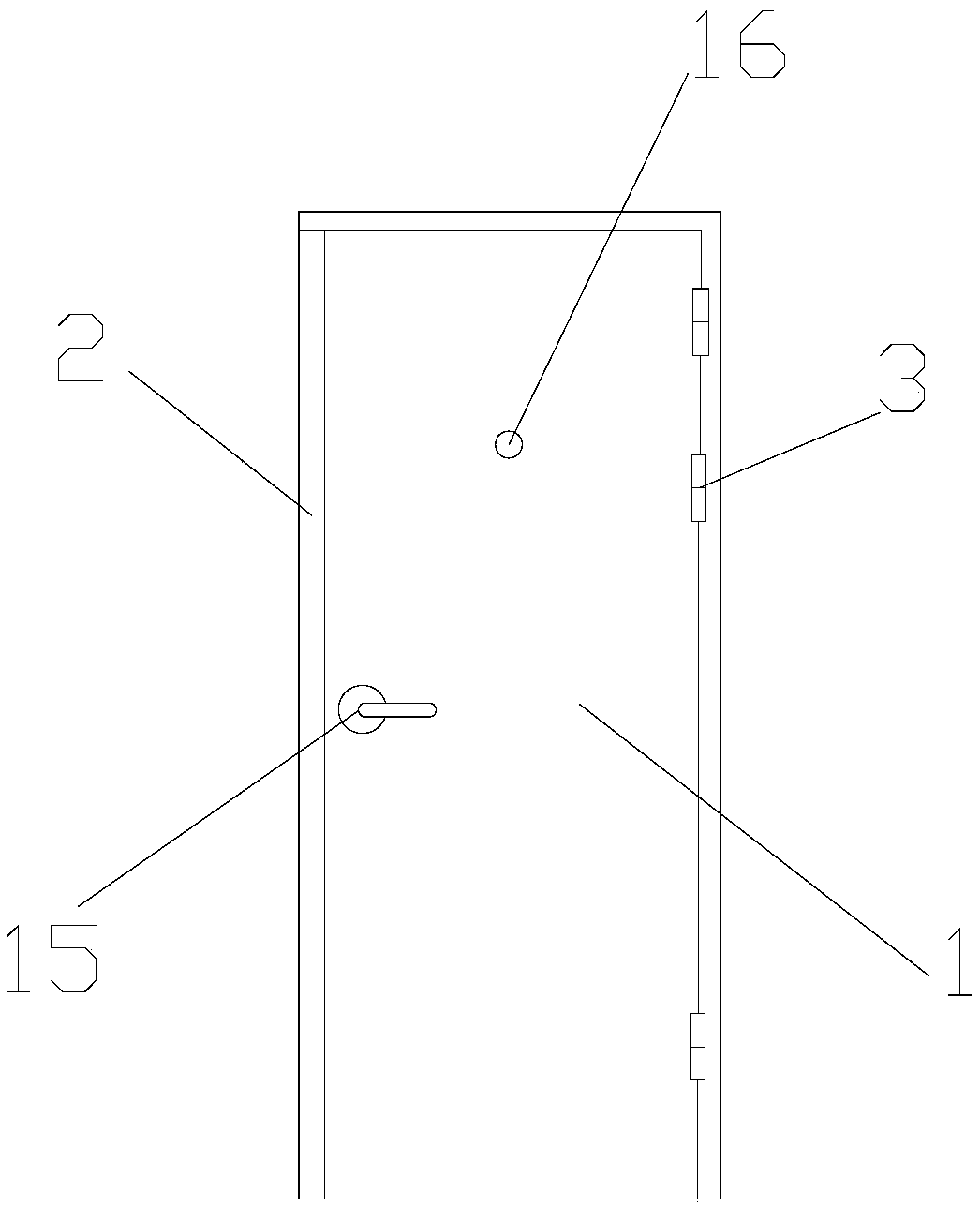

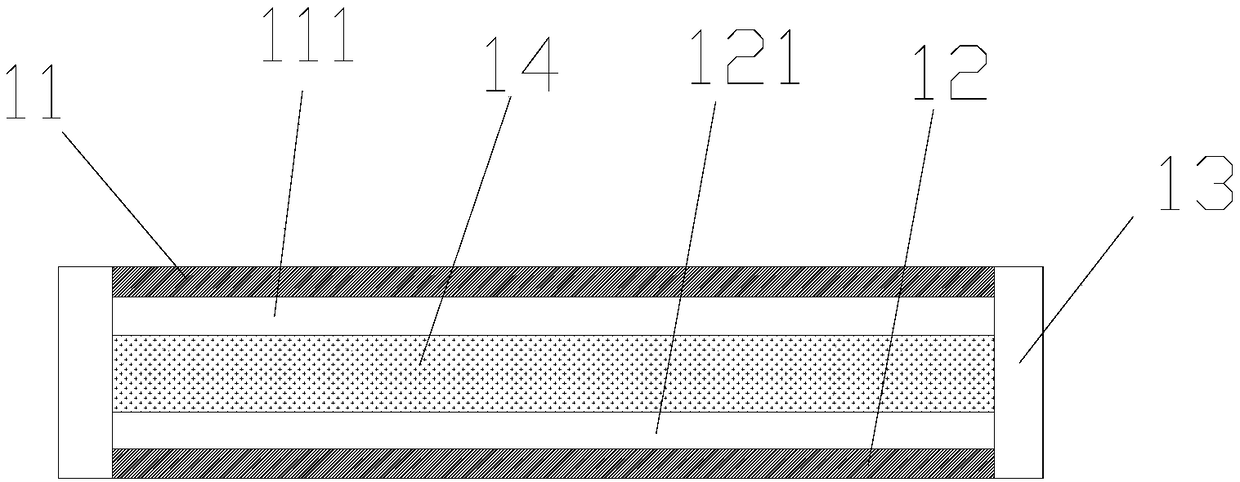

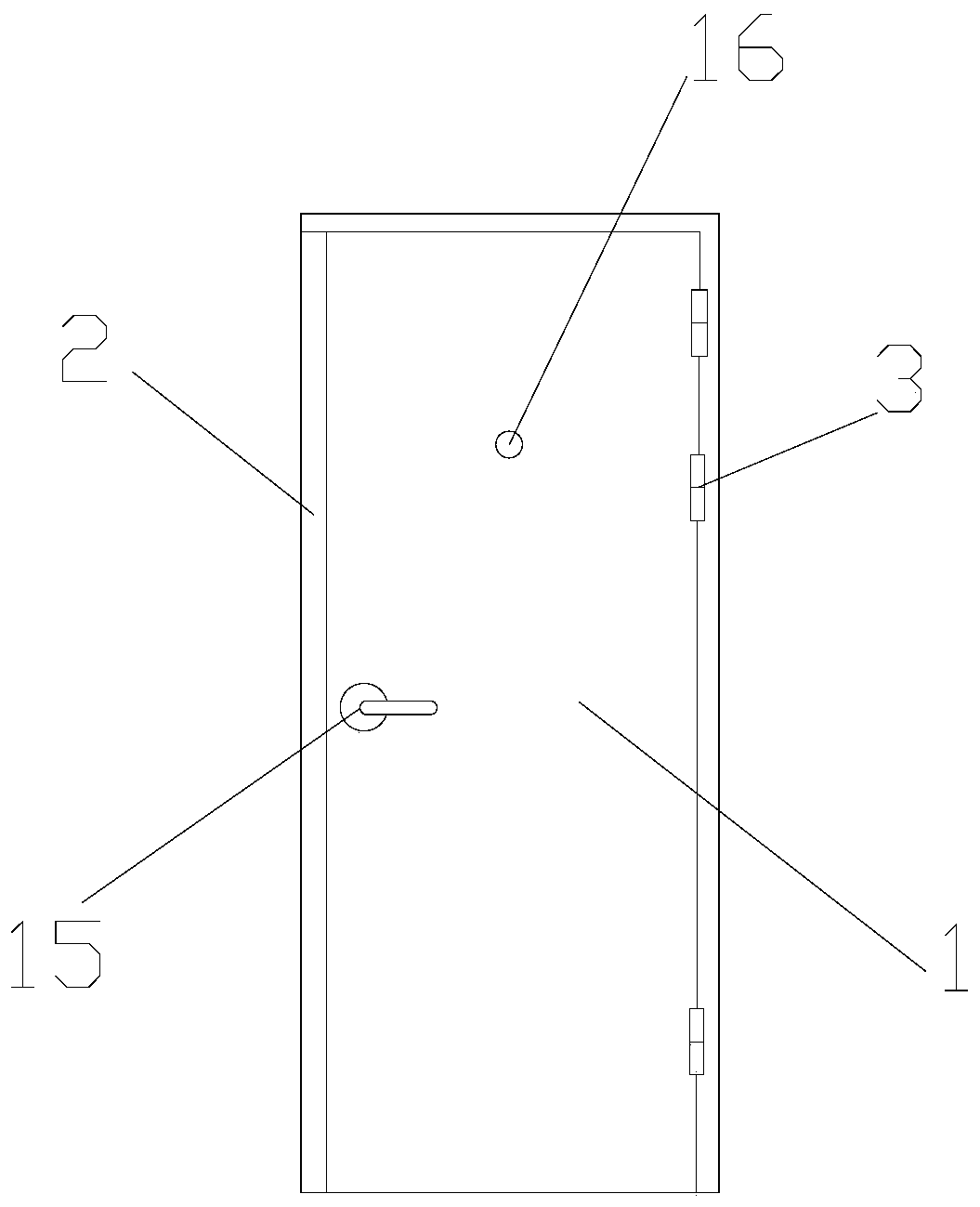

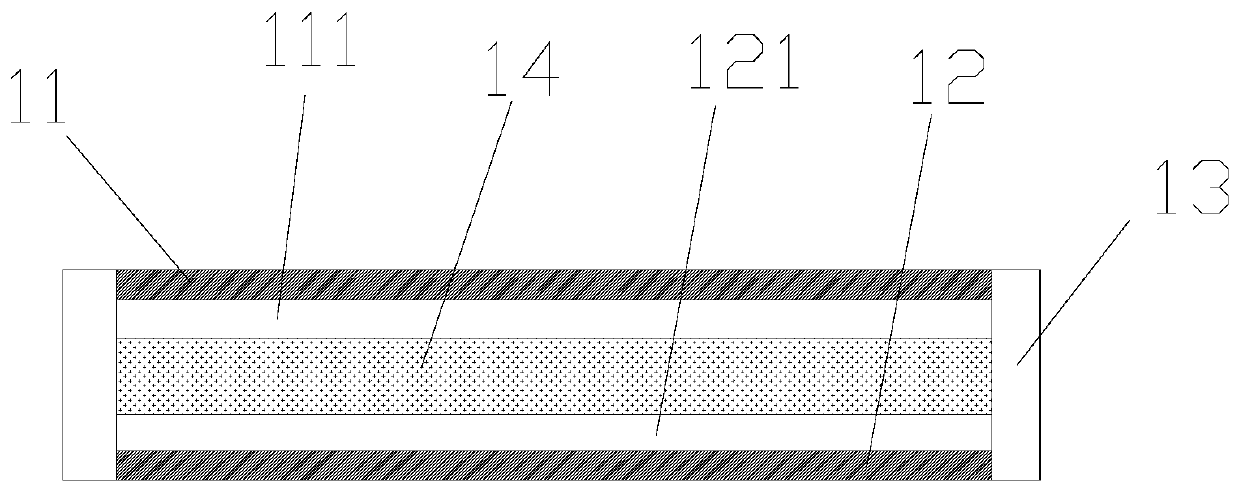

Soundproof composite door

ActiveCN108590470AHigh hardnessSound absorption and noise reduction effect is goodNoise insulation doors/windowsConstructions elementsMortise and tenonEngineering

The invention discloses a soundproof composite door. The soundproof composite door comprises a door panel and a door frame, the door panel comprises an inner soundproof board, an outer soundproof board disposed under the inner soundproof board and a frame which is connected with the inner soundproof board and the outer soundproof board through mortise and tenon and used for fixing the door panel.A first composite fiber board which is attached to the inner soundproof board and used for increasing the strength of the door panel is arranged on the lower surface of the inner soundproof board, anda second composite fiber board which is attached to the outer soundproof board and used for increasing the strength of the door panel is arranged on the upper surface of the outer soundproof board. Asound absorbing sponge layer is arranged between the first composite fiber board and the second composite fiber board. The soundproof composite door has the advantages of high hardness and good soundabsorption and noise reduction effects, is durable and safe and environmentally friendly, and is suitable for a variety of occasions.

Owner:ZHEJIANG YIMEIDA DOOR IND

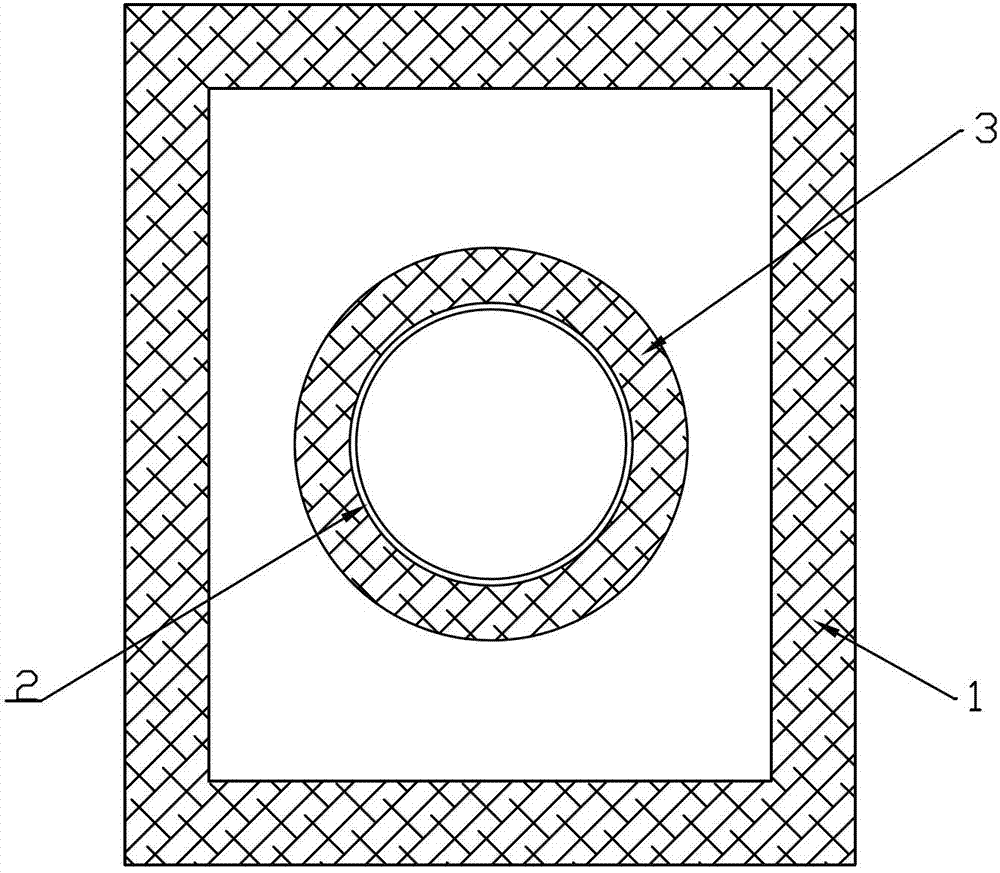

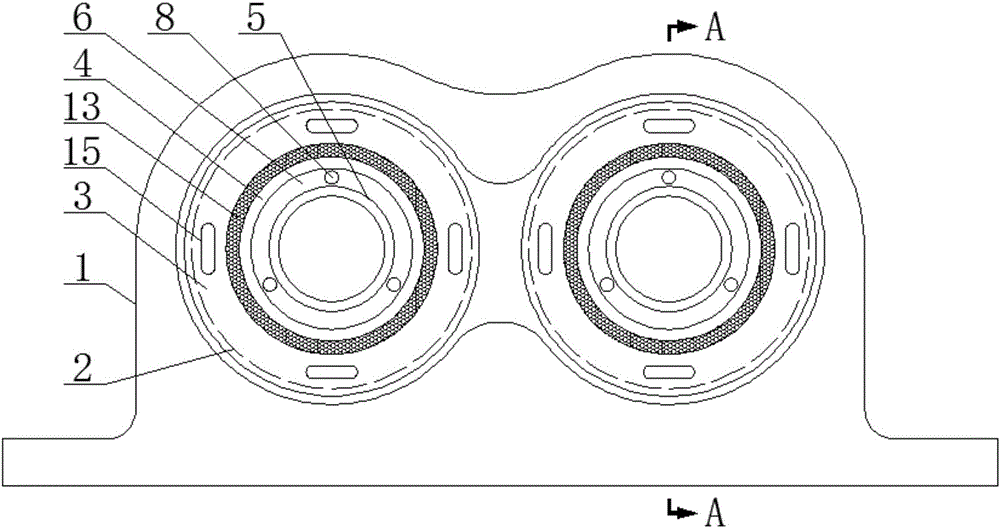

High-suitability sound absorbing and damping automobile exhaust pipe support

InactiveCN105863801AImprove adaptabilityMeet the requirementsExhaust apparatusSilencing apparatusEngineeringExhaust pipe

The invention discloses a high-suitability sound absorbing and damping automobile exhaust pipe support and relates to the mechanical field. The high-suitability sound absorbing and damping automobile exhaust pipe support comprises a support body which is provided with two installing holes; the axes of the two installing holes are parallel with each other; each installing hole is internally provided with a connection sleeve; and rubber layers are arranged between the connection sleeves and the installing holes. Each connection sleeve comprises an outer pipe, an inner pipe, front covers and rear covers, wherein the diameter of the outer pipe is large, the diameter of the inner pipe is small, the front covers and the rear covers are welded to the two ends of the outer pipe and the two ends of the inner pipe in a blocking manner, the front covers and the rear covers are all in the shape of a ring and are connected between the outer pipe and the inner pipe, the front covers are provided with a plurality of threaded holes, and the positions, close to the front covers, of the inner pipe are provided with pressing devices. A sound absorbing casing pipe is further connected between each connection sleeve and the corresponding rubber layer in a sleeving manner. The automobile exhaust pipe support has a good damping and noise lowering effect, is high in suitability and can adapt to exhaust pipes of different sizes, connection is tight, the exhaust pipes are not prone to looseness, the overall structure is compact, the weight is small, the automobile oil consumption is indirectly reduced, and the energy-saving performance is good.

Owner:波森尾气系统(沈阳)有限公司

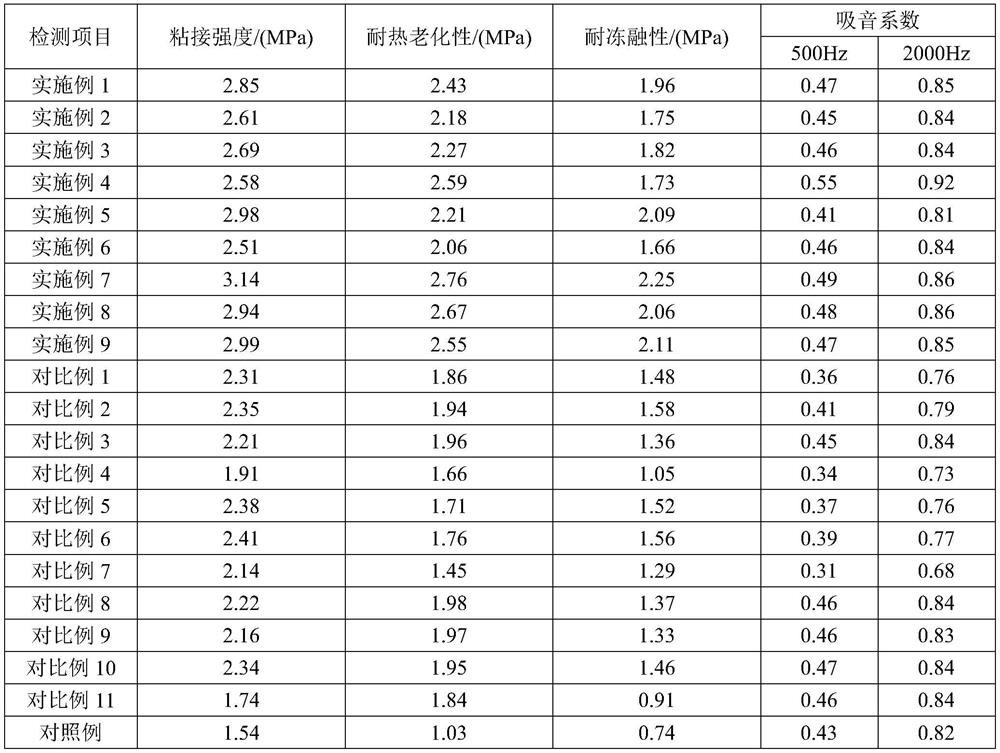

Two-component back coating material for rock plate and preparation method of two-component back coating material

ActiveCN114605885AHigh bonding strengthImprove heat aging resistanceSolid waste managementCoatingsPowder mixtureMaterials processing

Owner:河北匠工新型建筑材料有限公司

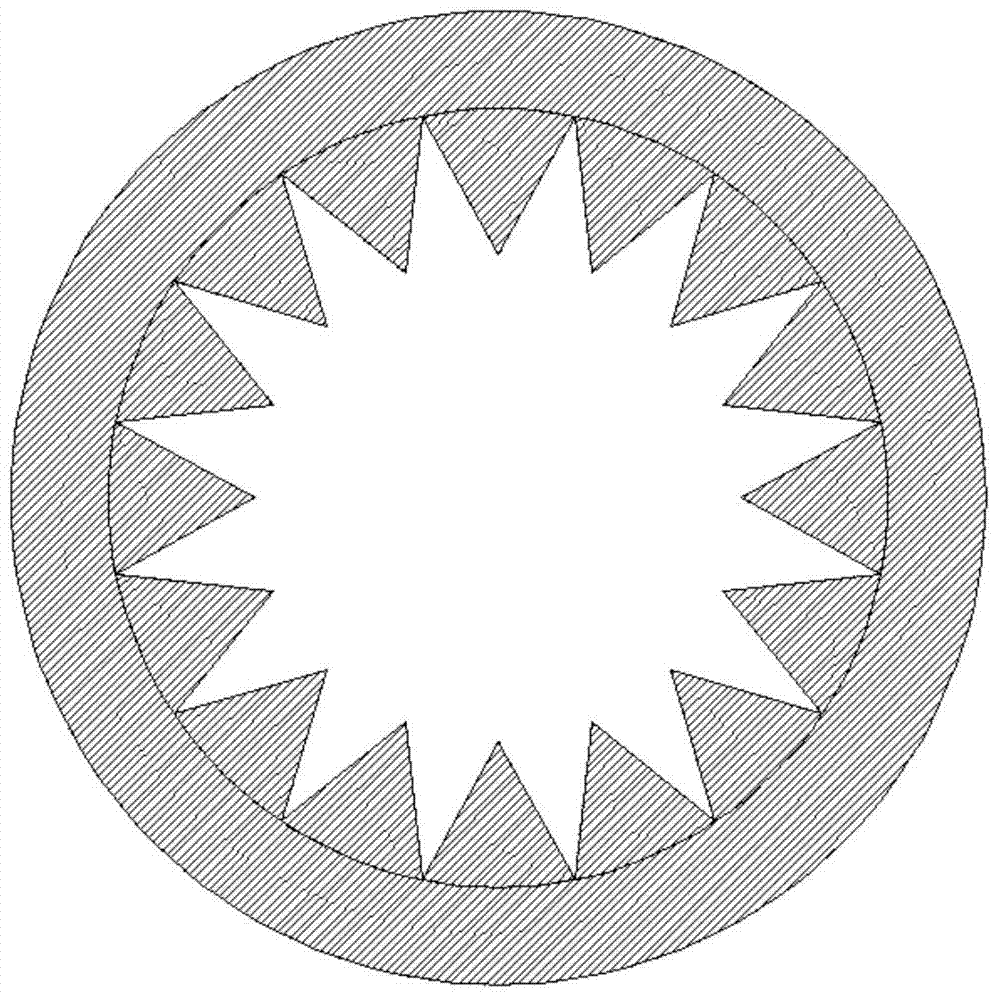

Sound-absorbing noise-reducing ceramic assembly

ActiveCN103951381APromote absorptionHigh strengthNoise reduction constructionClaywaresCeramicBuilding construction

The invention relates to a sound-absorbing noise-reducing ceramic assembly. The sound-absorbing noise-reducing ceramic assembly comprises at least one sound-absorbing noise-reducing ceramic unit; the sound-absorbing noise-reducing ceramic unit is multichannel cellular ceramic, and the channel inner wall of the multichannel cellular ceramic is in a porous structure. The ceramic assembly has excellent sound-absorbing and noise-reducing functions, and is suitable for sound-absorbing space indoor and outdoor, and is especially suitable for being used in outdoor sound-absorbing noise-reducing engineering such as highway, high speed railway, tunnel and subway, and the ceramic assembly has the obvious effect for absorbing sound and reducing noise, and has the advantages of convenient construction, good weatherability and environmental protection.

Owner:佛山中科产业技术研究院

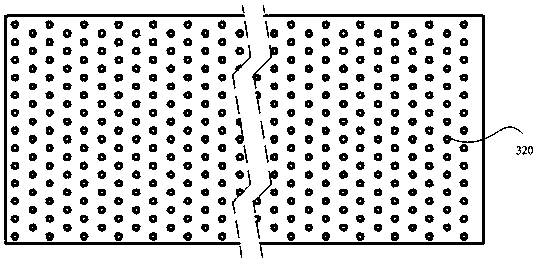

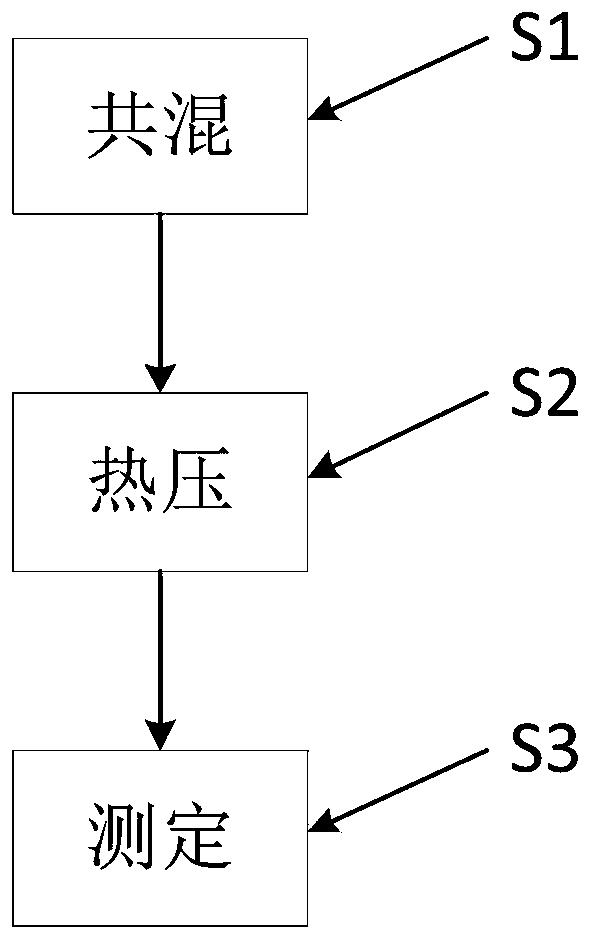

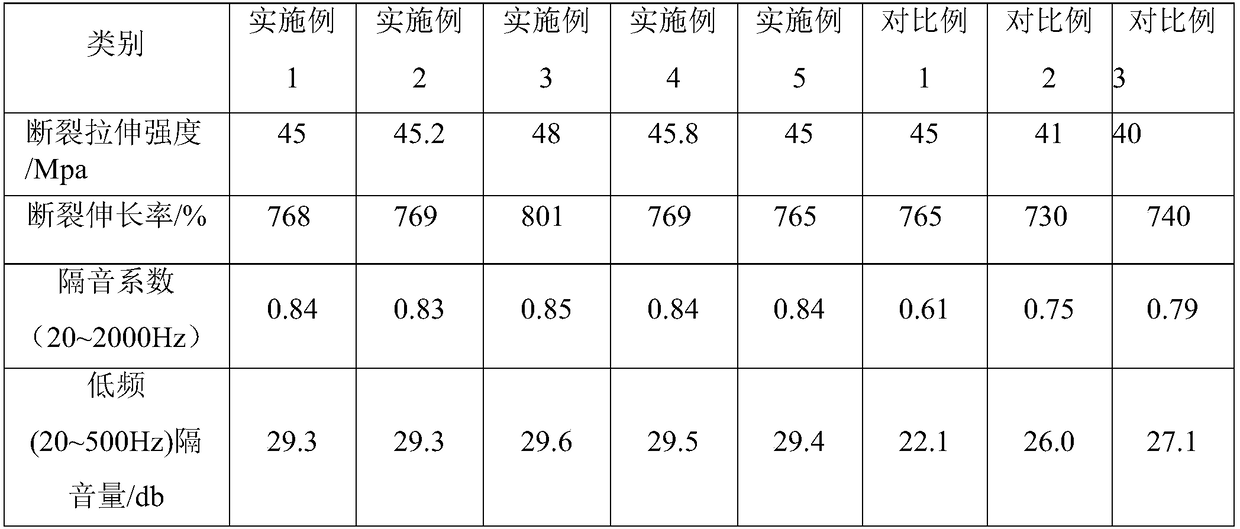

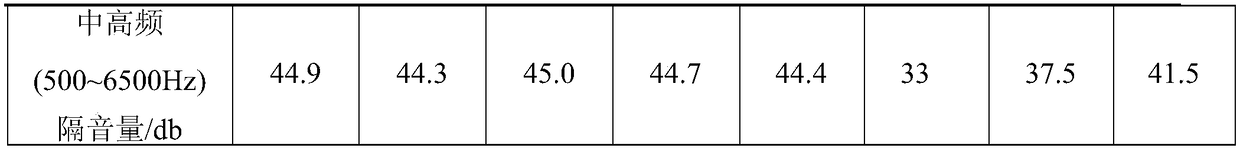

Preparation method for sound absorption and noise reduction material used for pneumatic tyres

InactiveCN109927198ASound absorption and noise reduction effect is goodImprove fatigue resistanceSound producing devicesFiberPolyester

The invention relates to a preparation method for a sound absorption and noise reduction material used for pneumatic tyres. The preparation method comprises the following steps that HXNBR is added toperform mixing after the temperature of a double-roller open mixing machine is set to be constant, then hollow polyester fiber is added, after the mixing is performed evenly, graphene fiber is added to continue to perform the mixing, and an HXNBR / hollow polyester fiber / graphene fiber mixture is obtained; the mixture is placed into a mold to be put into a slab vulcanizing machine and taken out after being pressed, then cooling demolding is performed, and an HXNBR / hollow polyester fiber / graphene fiber composite material is obtained; and the composite material is placed into the mold to be pressed and bonded with a nonwoven material after being placed into a constant temperature oven for preheating, and the sound absorption and noise reduction material is obtained. The preparation method forthe sound absorption and noise reduction material used for the pneumatic tyres is simple in step and easy to operate; by means of the preparation method for the sound absorption and noise reduction material used for the pneumatic tyres, the obtained sound absorption and noise reduction material has good sound absorption and noise reduction effect, and tyre noise is reduced by 10% or above; and bymeans of the preparation method for the sound absorption and noise reduction material used for the pneumatic tyres, the graphene fiber is introduced in, the fatigue resistance of the sound absorptionand noise reduction material is improved, and the service life of the sound absorption and noise reduction material is prolonged.

Owner:JIANGSU GENERAL SCI TECH

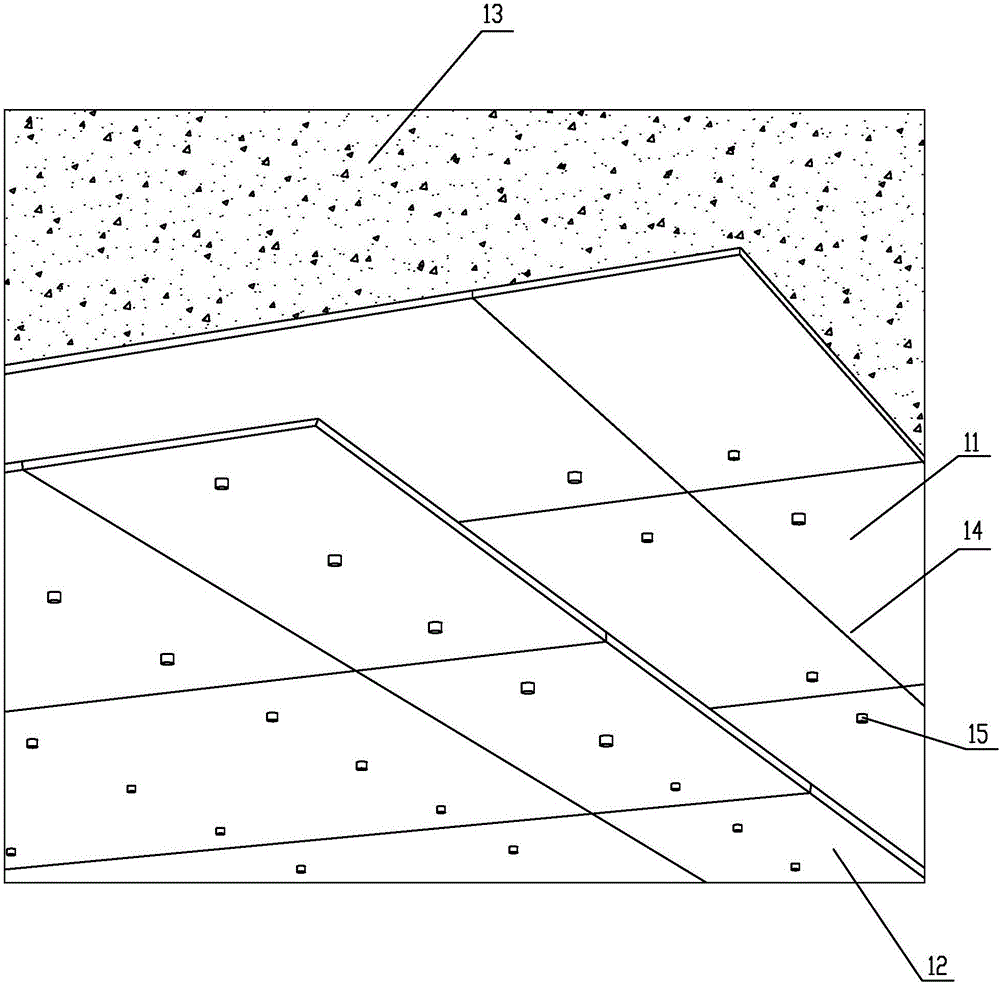

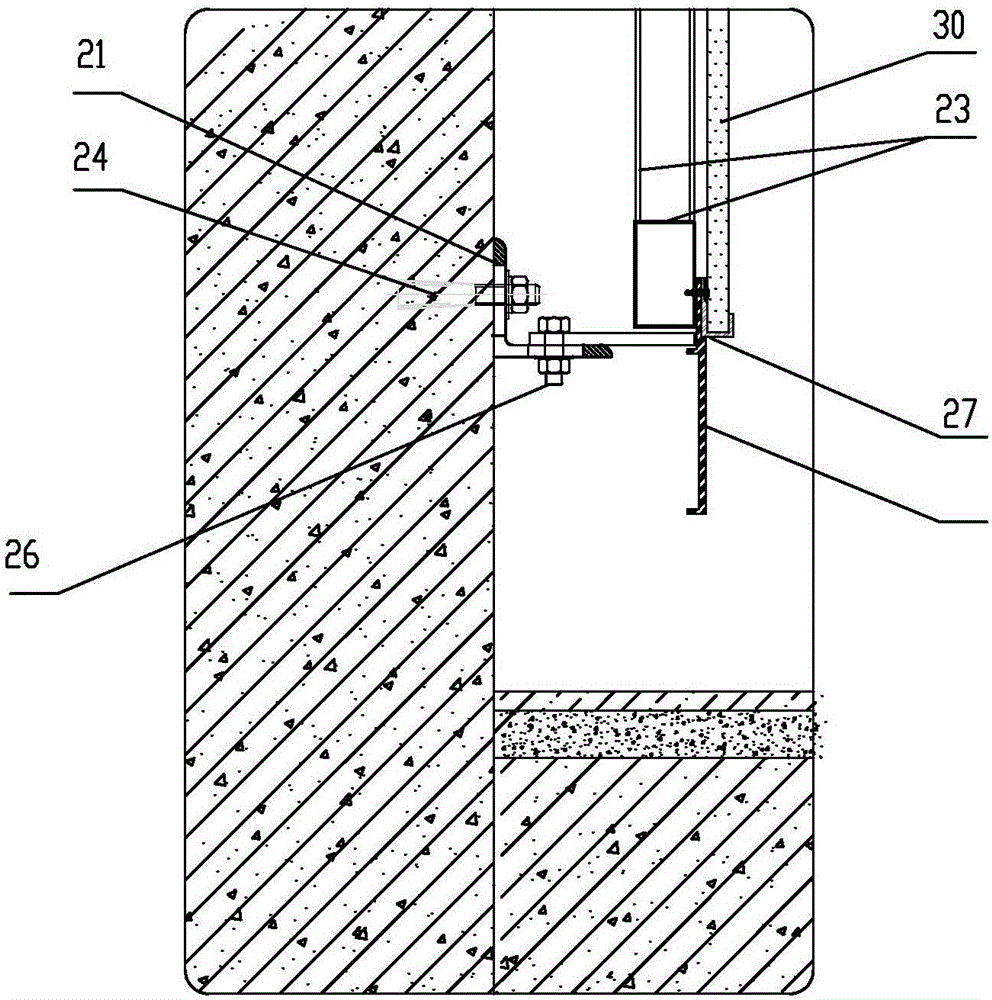

Fireproof plate for tunnel and mounting structure and construction method thereof

InactiveCN107524460AImprove flame retardant performanceImprove fire performanceUnderground chambersDust removalCalcium hydroxideAluminium hydroxide

The invention discloses a fireproof plate for a tunnel and further discloses a mounting structure and construction method of the fireproof plate for the tunnel. A top plate body at least comprises the following raw material components of, by mass, 3.5%-5% of timber, 3%-5.5% of cement bags, 32%-45% of quartz powder, 22%-32% of cement, 10%-20% of calcium hydroxide, 3%-5% of aluminium hydroxide and 0.5%-1% of bentonite; a side wall fireproof plate body at least comprises the following raw material components of, by mass, 4%-5.5% of timber, 2%-3.5% of cement bags, 40%-55% of quartz powder, 30%-45% of cement, 2%-4% of aluminium hydroxide and 0.6%-1.2% of bentonite. The fireproof plate adopting the material components is good in flame retarding effect, high in product strength and good in toughness and bending resistant performance. The fireproof security level of the tunnel is effectively promoted, and the sound absorption and noise reduction effects and the visual effect are all better.

Owner:广州市威保秀壁板业有限公司

Processing technique for noise-reducing steel pipe

The invention relates to a processing technique for a noise-reducing steel pipe. The processing technique comprises the following steps: (1) inserting a tubular mould into a seamless steel pipe and causing a gap between the seamless steel pipe and the mould to be 2-3mm; (2) filling the gap in the step (1) with a mixture of aluminum powder and foaming agent; (3) heating the steel pipe to be at 680 DEG C, keeping for 2 minutes, drawing out the mould and immediately cooling; (4) blowing down waste residue in the pipeline. The mould is made of a thermal shrinkage material and contracts under a high-temperature state; dolomite dust is selected as the foaming agent; the processing technique for the noise-reducing steel pipe has the beneficial effects that the sound wave energy in the pipe is absorbed, the processing technique is simple, the production cost is low, the sound-absorbing and noise-reducing effect is good, and the processing technique is easily popularized.

Owner:NANTONG ZHIBANG NEW MATERIAL TECH

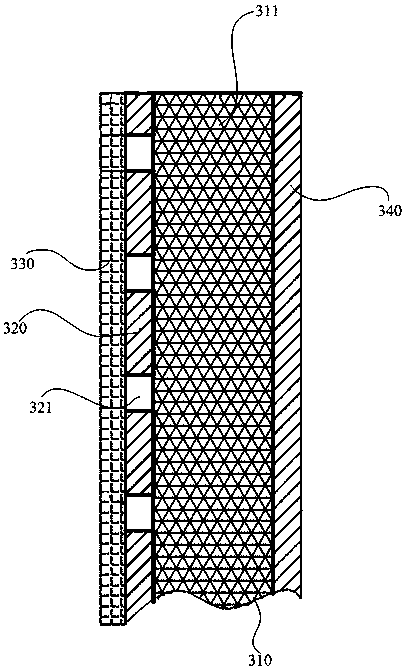

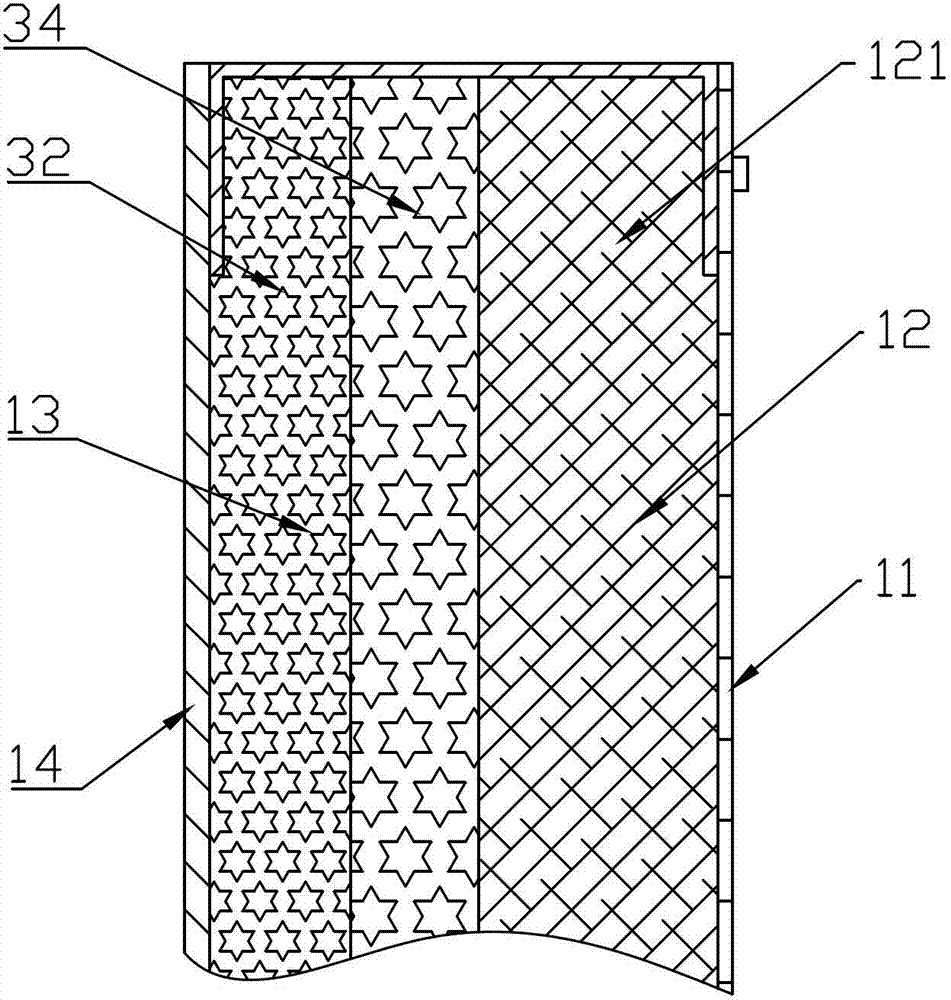

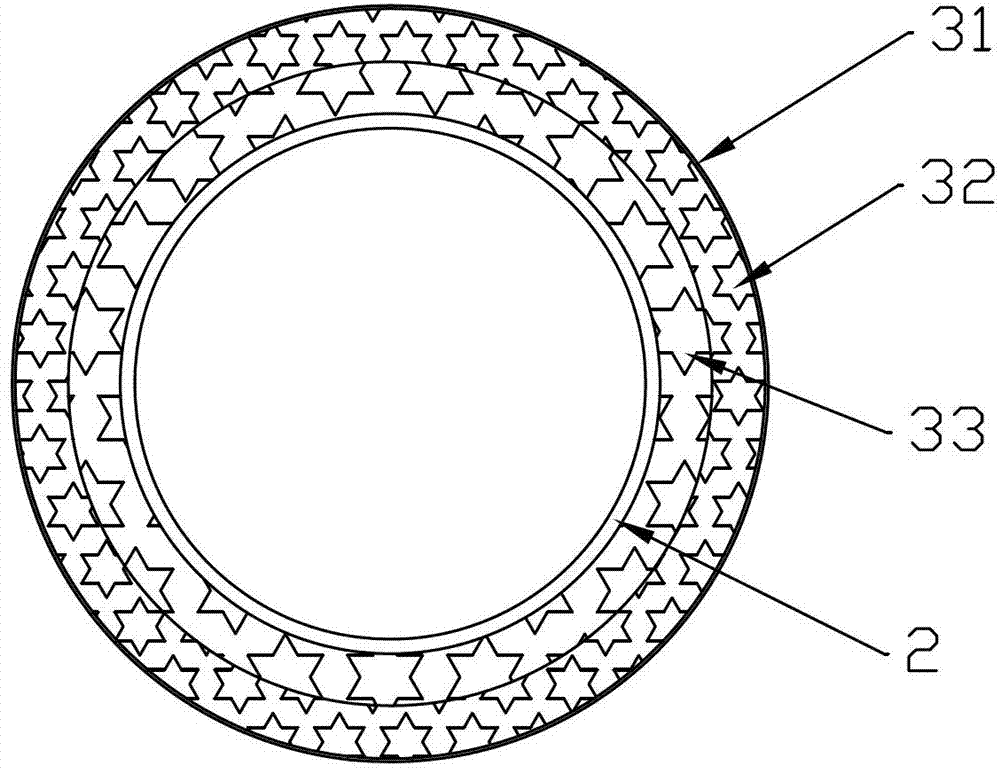

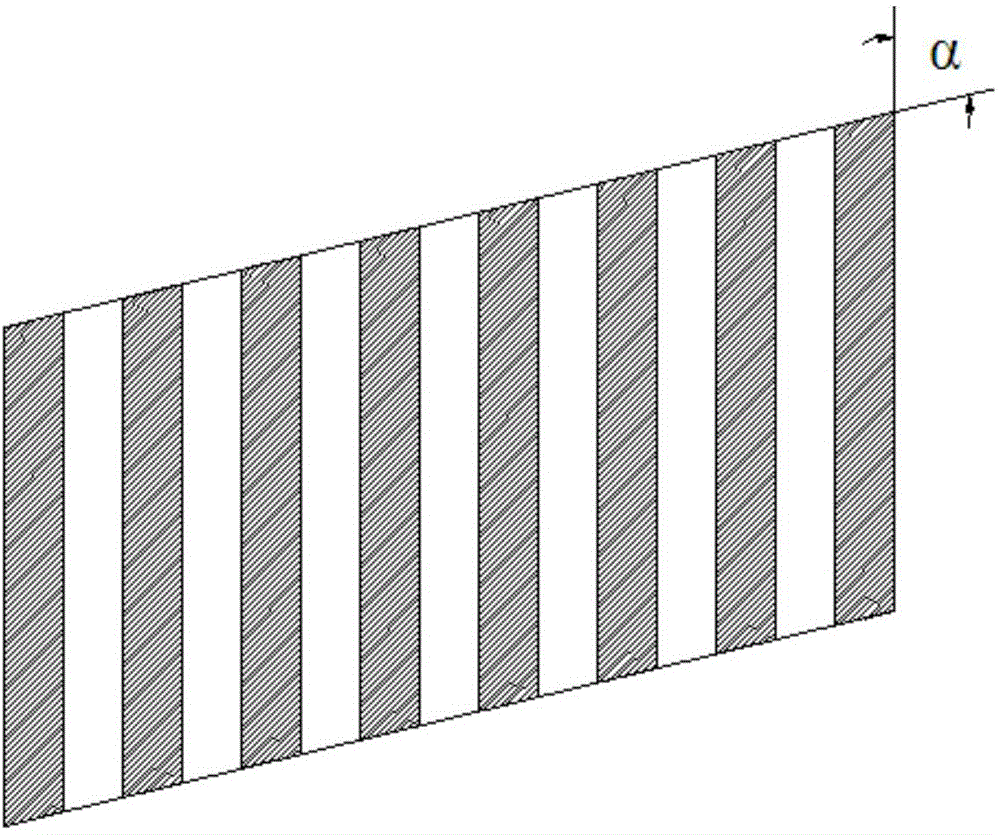

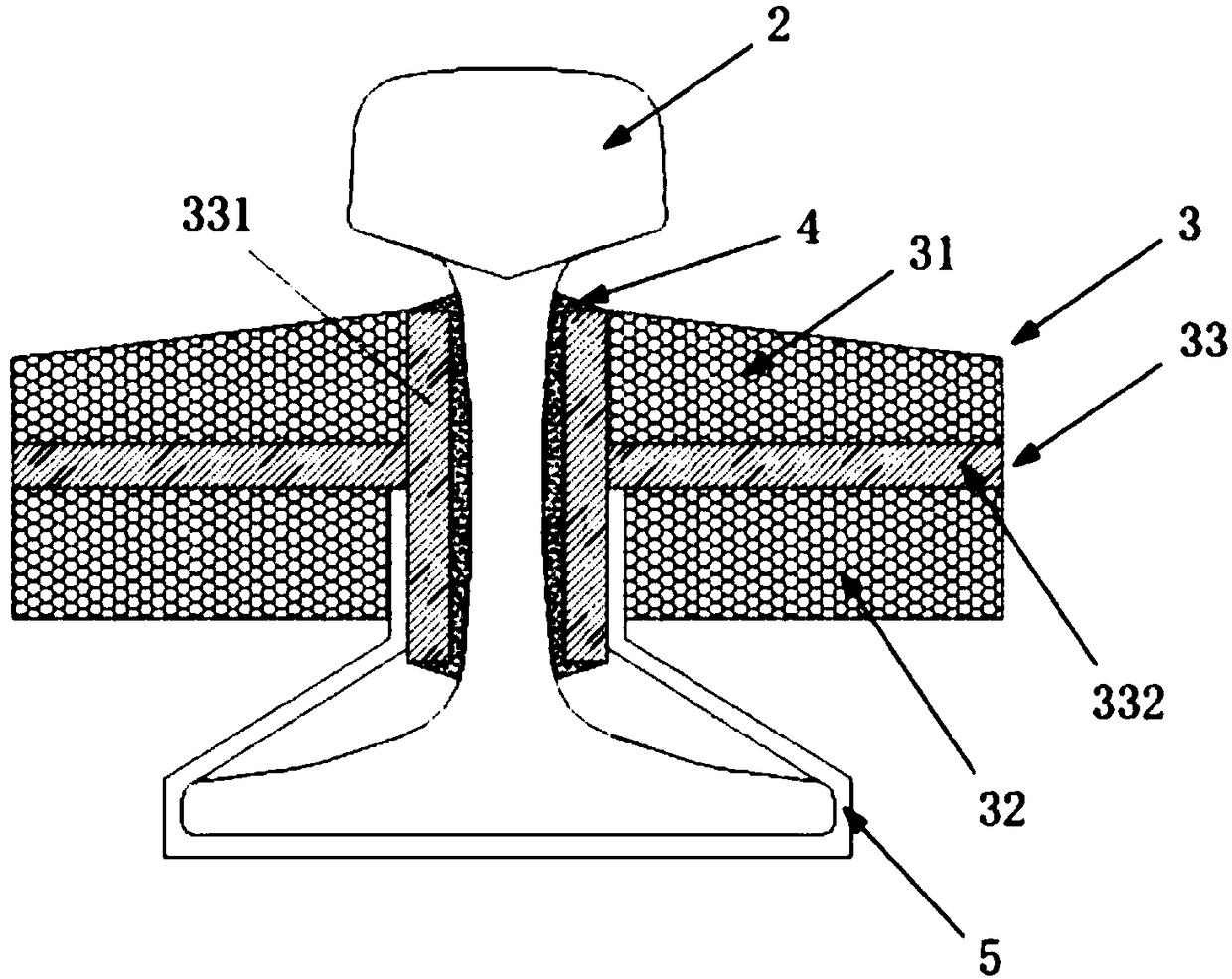

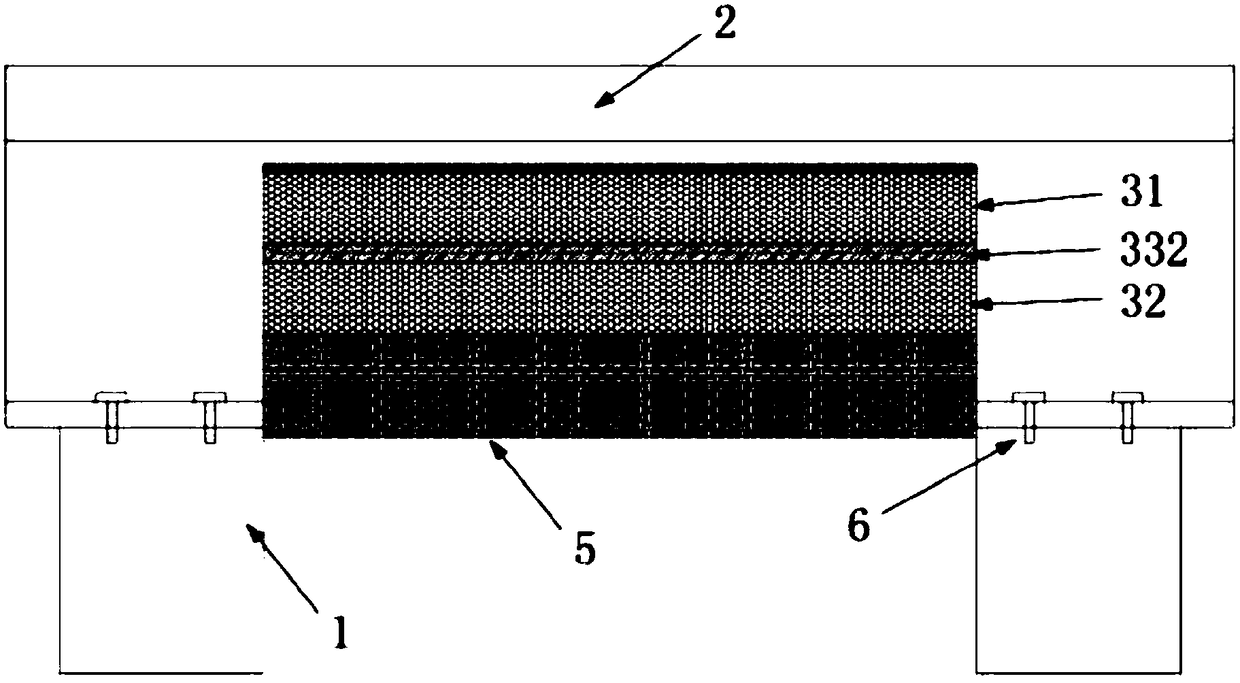

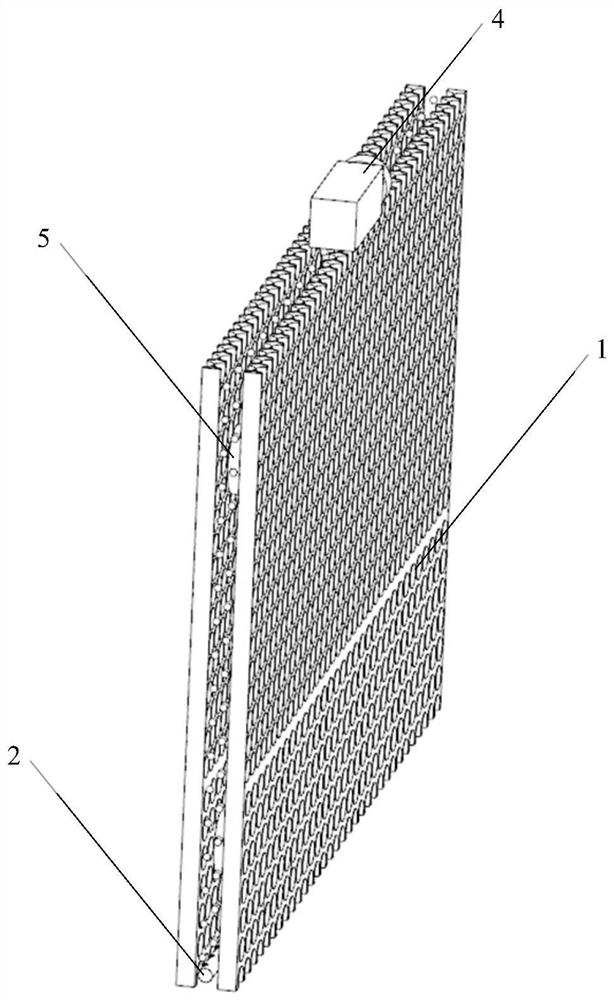

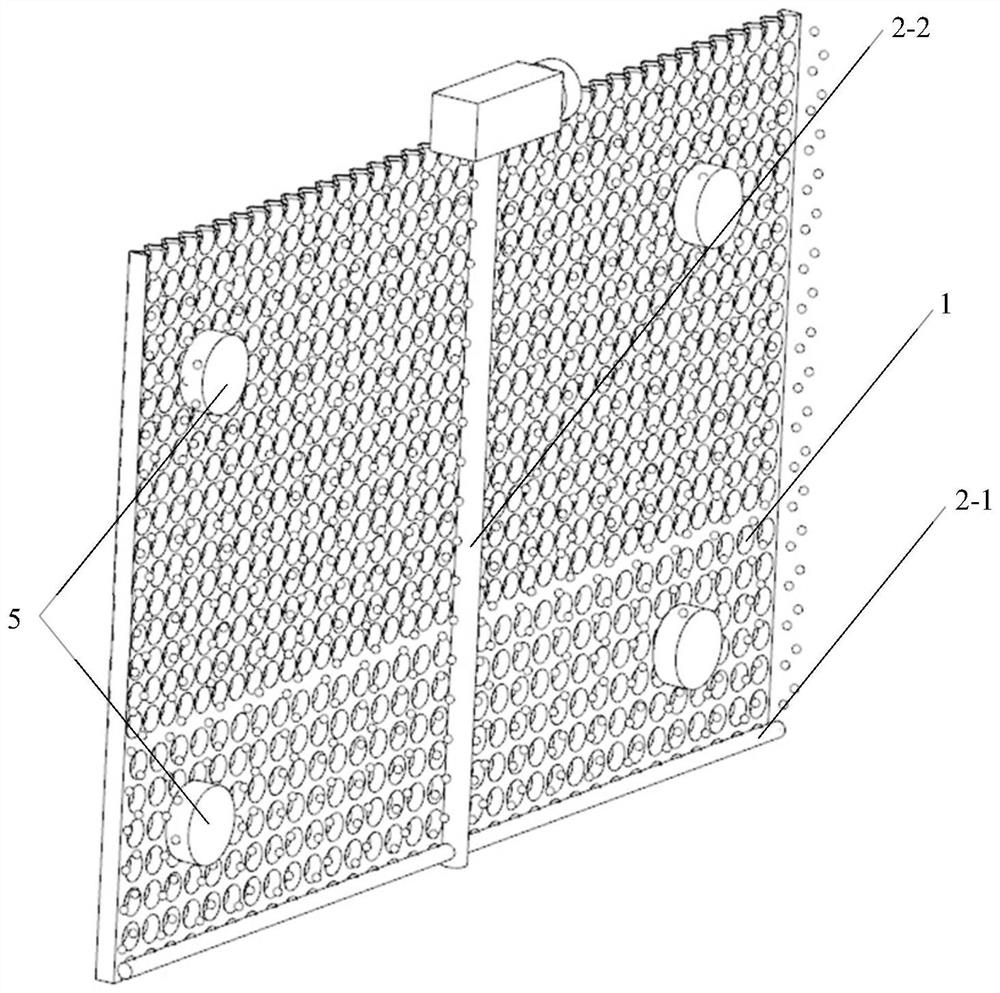

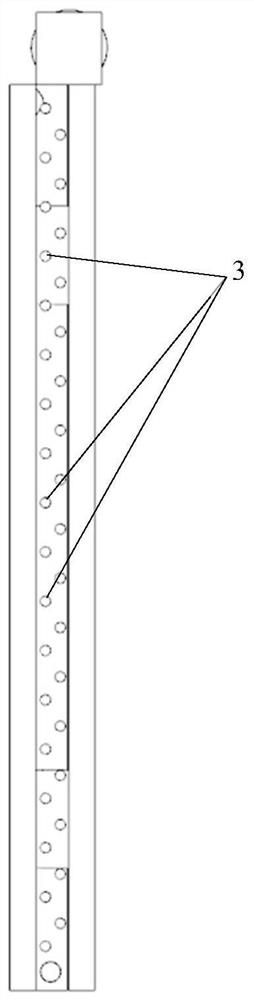

A double-sided sound-absorbing and noise-reducing device for a railway track and its installation method

ActiveCN106906701BEasy to implementSound absorption and noise reduction effect is goodRailway tracksEngineeringNoise reduction

The invention discloses a double-faced sound absorption and noise reduction device of a railway track, and an installation method thereof. The railway track comprises a plurality of sleepers (1) and steel rails (2) erected on the plurality of sleepers (1), the sound absorption and noise reduction device is installed on the steel rail (2) on a suspended segment between adjacent sleepers (1), the sound absorption and noise reduction device comprises two double-faced sound absorption boards (3), the two double-faced sound absorption boards (3) are respectively adhered on two sides of the steel rail (2) on the suspended segment through adhesion layers (4), each double-faced sound absorption board (3) comprises an upper sound absorption panel (31) and a lower sound absorption panel (32), the upper sound absorption panel (31) is arranged toward the upper side of the railway track, and the lower sound absorption panel (32) is arranged toward the bottom of the railway track. The sound absorption and noise reduction device has the advantages of easy implementation, low cost and good sound absorption and good noise reduction effect.

Owner:CENT SOUTH UNIV

Bubble curtain/foam board composite device for underwater sound absorption and noise reduction and noise reduction method

PendingCN112967706ASound absorption and noise reduction effect is goodImprove sound absorption and noise reduction effectSound producing devicesWater flowEngineering

The invention discloses a bubble curtain / foam board composite noise reduction method for underwater sound absorption and noise reduction. The method comprises the following steps: enabling bubbles to move upwards between two opposite porous surfaces of two foam boards to form a bubble curtain, and realizing the combination of bubble curtain noise reduction and foam material noise reduction. By means of the porous surface of the foam board, bubbles can be continuously refined through collision of the foam board and the foam board in the bubble rising process, and therefore the sound absorption and noise reduction effects of the bubble curtain are further enhanced; and the foam plate can support the bubble curtain, the influence of airflow and water flow on the bubble curtain is weakened, and the noise reduction effect is stabilized.

Owner:清研特材科技(洛阳)有限公司

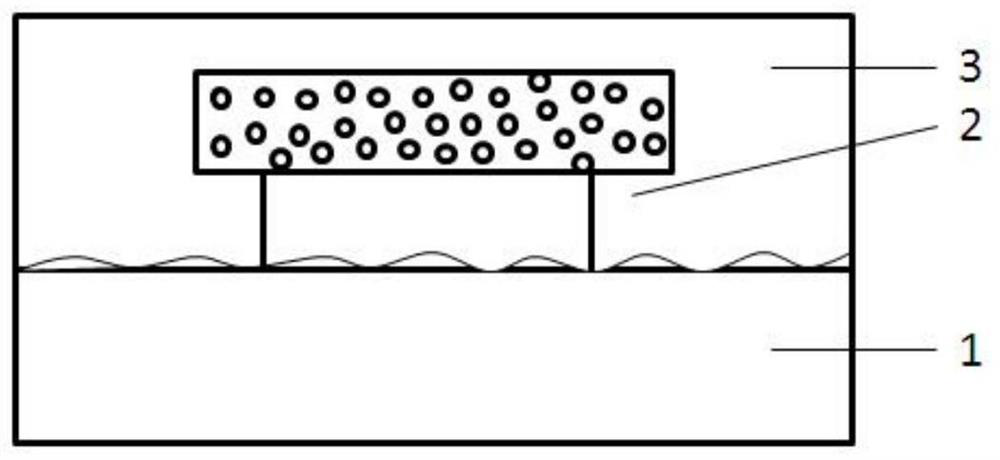

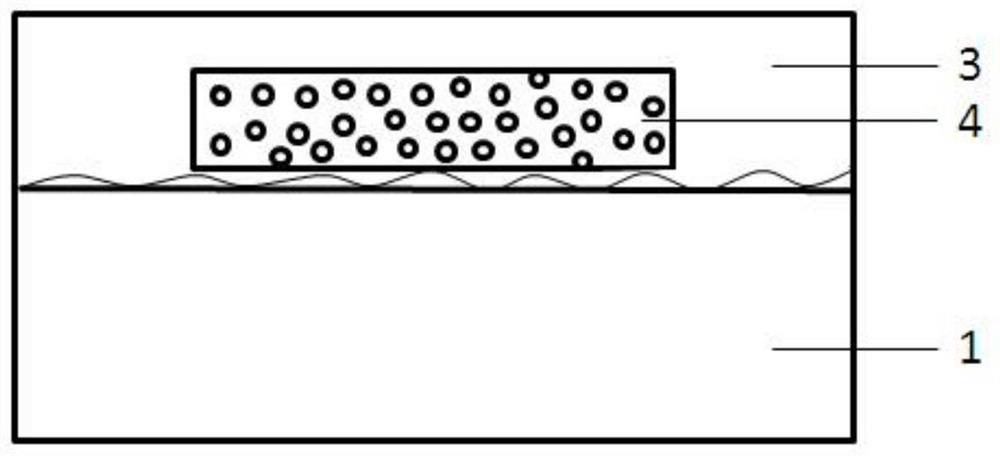

A kind of preparation method of engine cover

ActiveCN107973891BImprove shielding effectIncrease reflective areaDomestic articlesMicro perforated plateInjection moulding

The invention provides a preparation method for an engine cover lid. The method comprises the following steps: after a skin layer generating agent is subjected to reaction and injection moulding, a skin layer with a wavy structure is obtained; a micro perforated plate is placed on the wavy surface of the skin layer, a foam layer generating agent is poured on the micro perforated plate, and mold closing is carried out; and after molding is performed, mold opening is carried out, and therefore the engine cover lid is obtained. The engine cover lid provided by the invention includes a foam layerand the skin layer covering the foam layer, wherein the foam layer is rich in foam and the micro perforated plate, so that noise generated by an engine can be better absorbed; the wavy surface of theskin layer can reflect the noise from the engine back to the foam layer, thereby prolonging the standing time of the noise in the foam layer, giving play to better sound-absorbing and noise-reducing effects, and facilitating acquirement of better mute of a cab; and at the same time, the non-wavy surface of the skin layer has a good appearance, so that the visual requirements of users can be met.

Owner:芜湖飞利汽车零部件有限公司

Non-woven fabric wheel cover and one-time forming method thereof

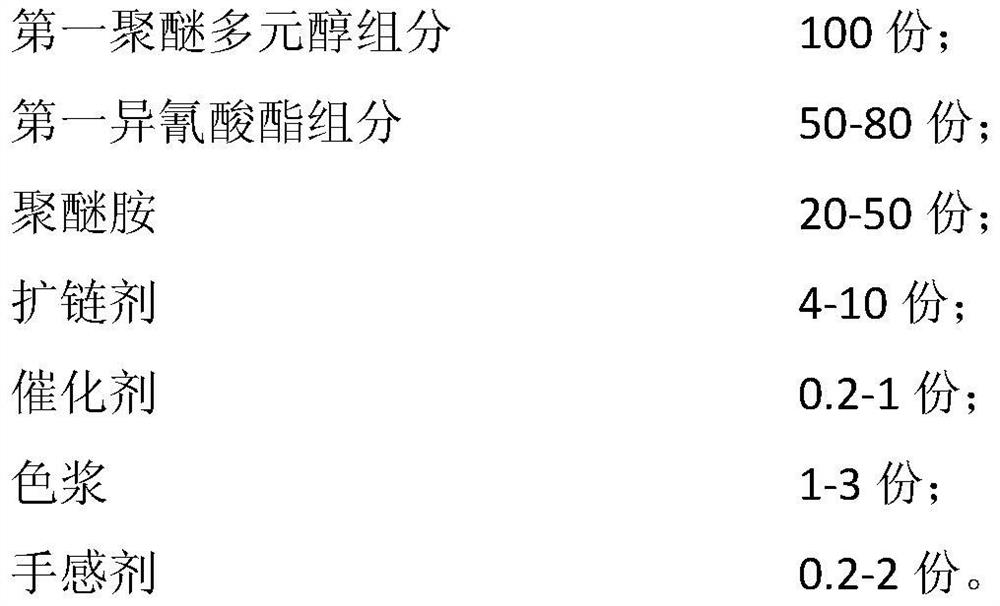

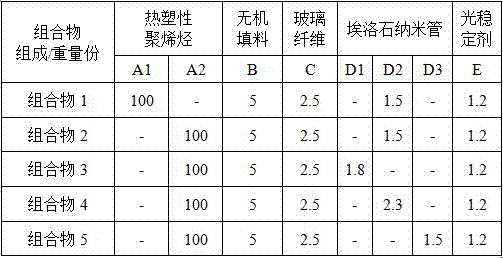

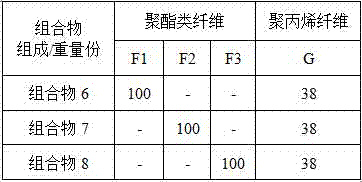

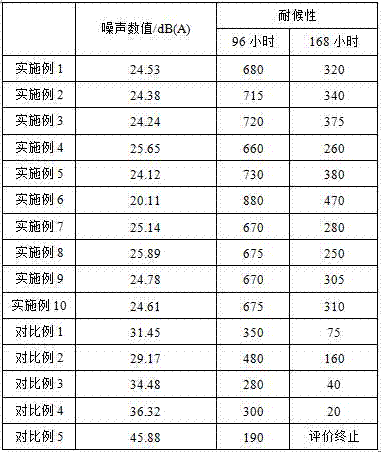

The invention provides a nonwoven fabric wheel casing which at least comprises a thermoplastic plastic frame and a nonwoven fabric located in the thermoplastic plastic frame.The thermoplastic plastic frame keeps the overall shape of the nonwoven fabric wheel casing and is connected with a bumper bar and an automobile body.The thermoplastic plastic frame is prepared from, by weight, 100 parts of thermoplastic polyolefin, 0.05-15 parts of inorganic filler, 0.01-5 parts of glass fiber, and 0.01-5 parts of halloysite nanotubes.The nonwoven fabric is prepared from, by weight, 100 parts of polyester fiber and 20-45 parts of polypropylene fiber.The nonwoven fabric is stable in performance, good in sound insulation effect, capable of being used in common conditions and capable of better meeting special requirement of rain, snow and other severe weather and complex road conditions for the wheel casing.

Owner:上海天原集团胜德塑料有限公司

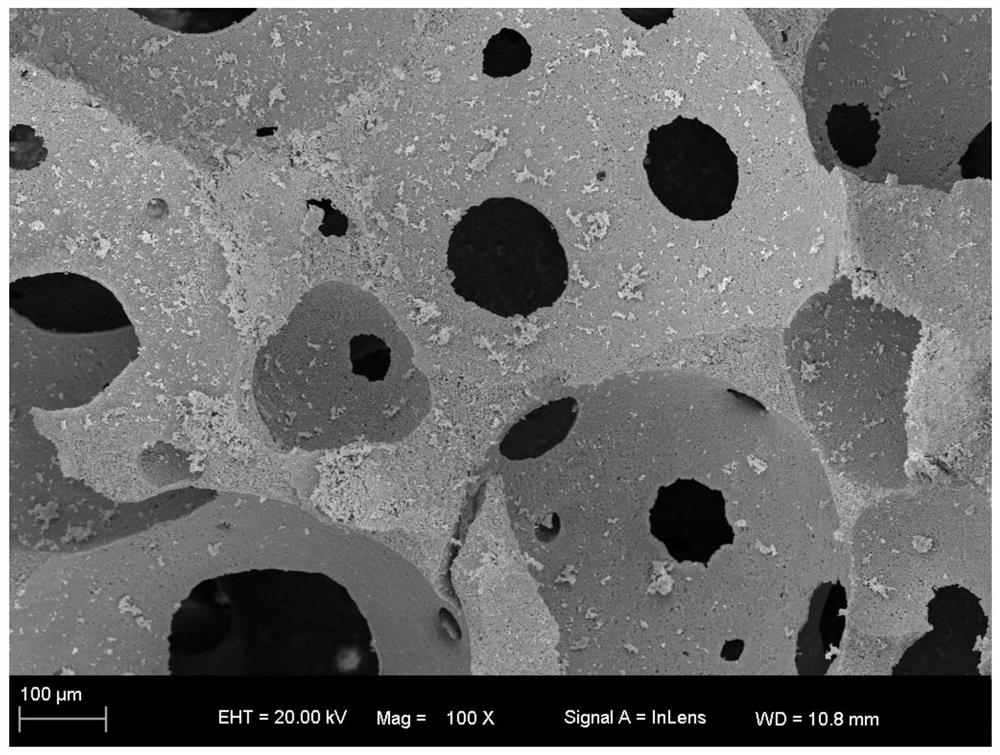

A sound-absorbing and noise-reducing porous ceramic used in substations

The invention discloses a sound-absorbing and noise-reducing porous ceramic used in substations. Its preparation includes the following steps: S1: mixing an adhesive A, albite and commercial alumina to obtain a mixed powder a; S2: mixing the mixed powder a Add deionized water to mix, add dispersant and gelling agent B to the slurry, and ball mill at 250 rpm for 3~5h to obtain slurry b; S3: ball mill slurry b for 6~12h, then add foaming agent C, ball milling for 20-30 minutes, heating in a water bath at 80°C for 8-12 minutes, and pouring into a mold; S4: drying at room temperature for 4-6 hours, demoulding, and drying in an oven at 70°C for 5-8 hours to obtain green embryos; S5 : Heat up to 200°C at a speed of 3°C / min, keep warm for 30~40min, then raise the temperature to 1350~1450°C at a speed of 3~4°C / min, keep warm for 2~4min, then cool to room temperature with the furnace.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD JINHUA POWER SUPPLY CO +3

soundproof composite door

ActiveCN108590470BHigh hardnessSound absorption and noise reduction effect is goodNoise insulation doors/windowsConstructions elementsFiberMortise and tenon

The invention discloses a soundproof composite door. The soundproof composite door comprises a door panel and a door frame, the door panel comprises an inner soundproof board, an outer soundproof board disposed under the inner soundproof board and a frame which is connected with the inner soundproof board and the outer soundproof board through mortise and tenon and used for fixing the door panel.A first composite fiber board which is attached to the inner soundproof board and used for increasing the strength of the door panel is arranged on the lower surface of the inner soundproof board, anda second composite fiber board which is attached to the outer soundproof board and used for increasing the strength of the door panel is arranged on the upper surface of the outer soundproof board. Asound absorbing sponge layer is arranged between the first composite fiber board and the second composite fiber board. The soundproof composite door has the advantages of high hardness and good soundabsorption and noise reduction effects, is durable and safe and environmentally friendly, and is suitable for a variety of occasions.

Owner:ZHEJIANG YIMEIDA DOOR IND

Preparation method of polyester imide enamelled wire insulating varnish

InactiveCN107603466AImprove impact resistanceImprove mechanical propertiesCoatingsPolyesterMechanical property

The invention discloses a preparation method of polyester imide enamelled wire insulating varnish. The preparation method comprises the following steps: firstly, taking calcium chloride and sodium hydrogen phosphate as raw materials, taking ammonium bicarbonate as a pore-foaming agent and carrying out spray drying to obtain porous hydroxyapatite; secondly, dispersing the porous hydroxyapatite intowater to obtain porous hydroxyapatite suspension, mixing the porous hydroxyapatite suspension with styrene-butadiene latex, and carrying out centrifugal spray drying by using a centrifugal spray drier to obtain porous hydroxyapatite-butadiene styrene rubber hybrid powder; finally, mixing the porous hydroxyapatite-butadiene styrene rubber hybrid powder with polyester imide resin and carrying out high-temperature reaction in an organic solvent, thus obtaining the polyester imide enamelled wire insulating varnish. The polyester imide enamelled wire insulating varnish prepared by the preparationmethod disclosed by the invention has the advantages of high impact resistance, good mechanical performance and high insulation reliability; in addition, the polyester imide enamelled wire insulatingvarnish has good effects of vibration reduction and noise reduction.

Owner:铜陵市永创变压器电子有限公司

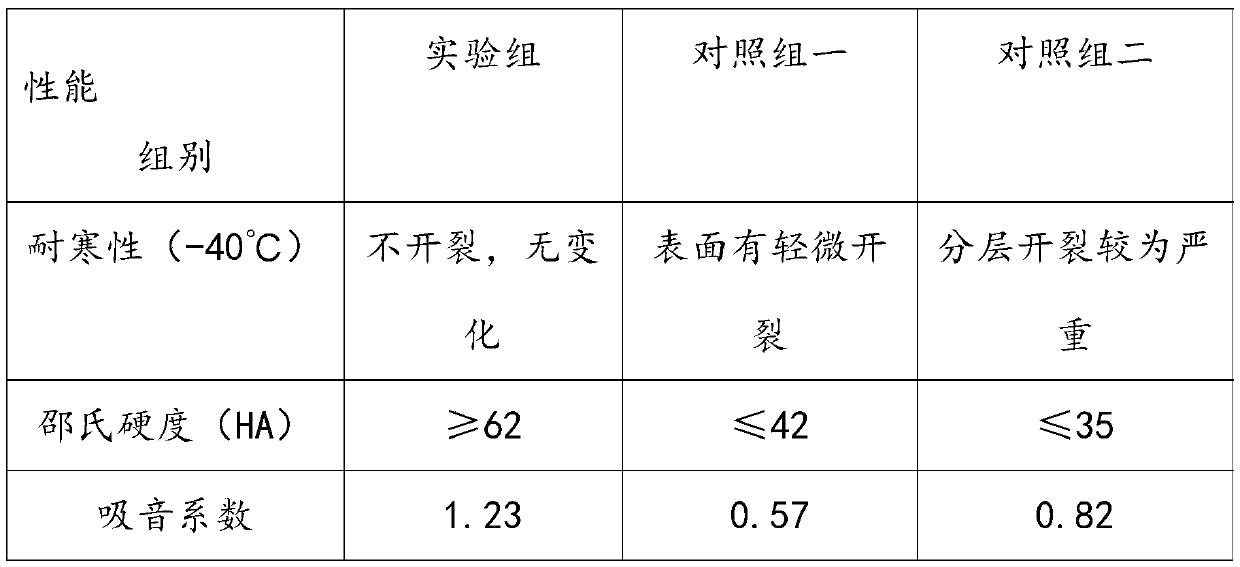

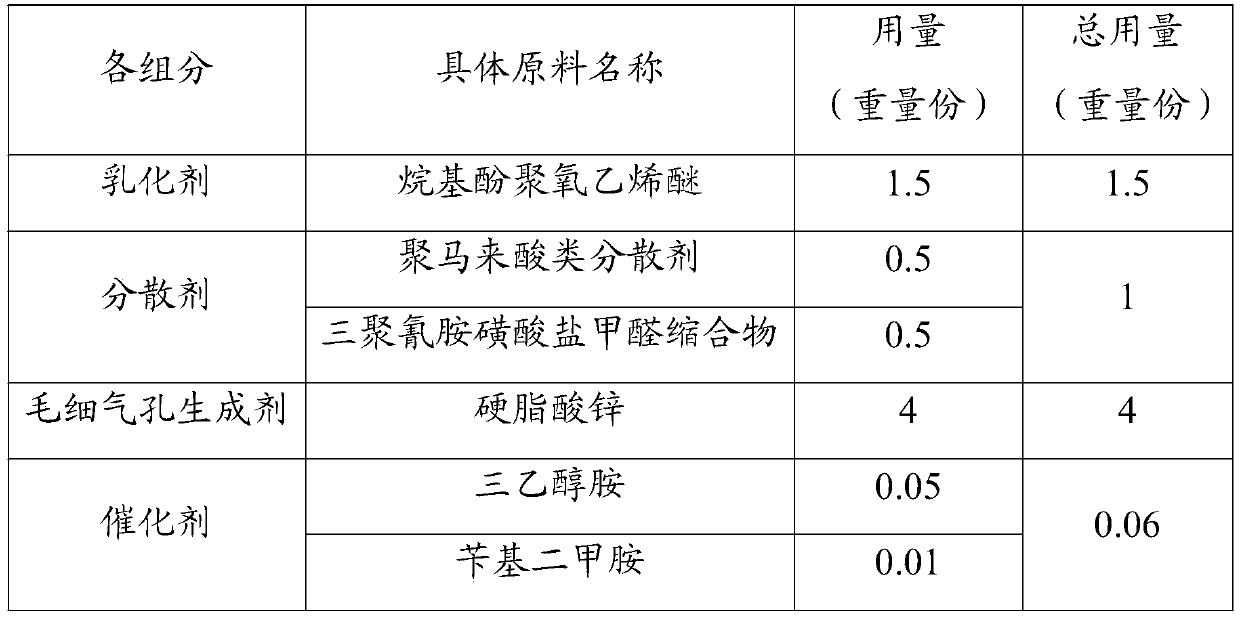

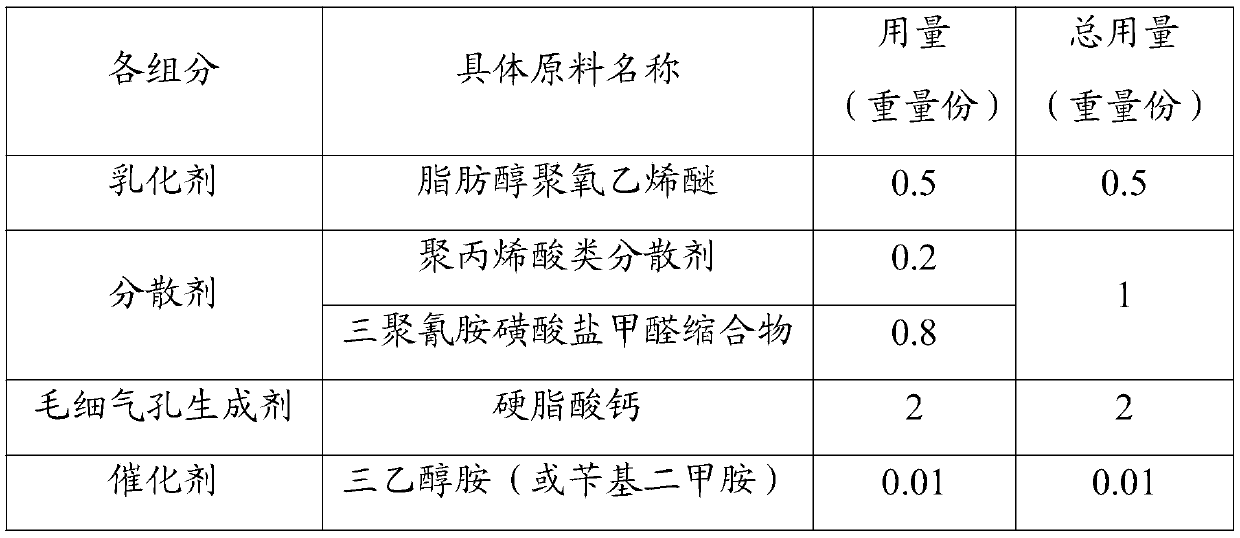

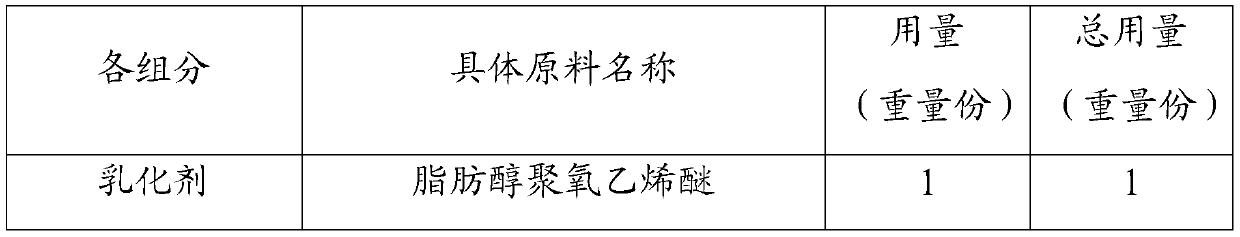

Permeable asphalt admixture, permeable asphalt and permeable asphalt pavement

The invention discloses a permeable asphalt admixture, permeable asphalt and a permeable asphalt pavement. The preparation raw materials of the permeable asphalt admixture comprise the following components in parts by weight: 0.5 to 1.5 parts of an emulsifying agent, 1 part of a dispersing agent, 2 to 4 parts of a capillary pore forming agent and 0.01 to 0.06 part of a catalyst. The permeable asphalt is prepared by uniformly mixing the permeable asphalt admixture and asphalt. The permeable asphalt pavement contains the permeable asphalt admixture. According to the permeable asphalt admixture,the permeable asphalt and the permeable asphalt pavement, the problems of early loosening, easiness in gap blockage in use, low strength, great construction difficulty and high cost in the existing permeable asphalt pavement are solved, and the permeable asphalt pavement has the advantages that the construction performance is excellent, the cost is low, the constructed permeable asphalt pavement is compact in structure and high in strength, gaps are not easily blocked in use, the continuous permeability is high, and the anti-fouling and anti-blockage performance is high.

Owner:武乡县泓晨万聚环保科技有限公司

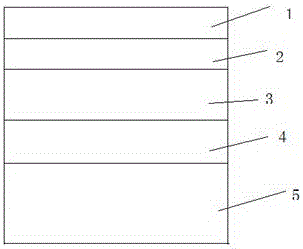

Fireproof sound-absorption noise-reduction rock wool board

InactiveCN106088505AImprove fire performanceSound absorption and noise reduction effect is goodCovering/liningsConstructions elementsCyanoacrylateGlass fiber

The invention discloses a fireproof sound-absorption noise-reduction rock wool board which is formed by combining a protection layer, a fireproof layer, a sound-absorption layer, a noise-reduction layer and a base layer. The protection layer is an insulation protection layer, the fireproof layer adopts polyvinyl chloride rubber, the sound-absorption layer adopts glass fiber sound-absorption cotton, the noise-reduction layer adopts centrifugal glass wool, the base layer is a rock wool board, and the protection layer, the fireproof layer, the sound-absorption layer, the noise-reduction layer and the base layer are bound through cyanoacrylate. In this way, the fireproof sound-absorption noise-reduction rock wool board can have a good fireproof effect and have good sound-absorption and noise-reduction effects.

Owner:常熟嘉淀新材料科技有限公司

A sound-absorbing and noise-reducing ceramic component

ActiveCN103951381BPromote absorptionHigh strengthNoise reduction constructionClaywaresAcoustic noise reductionCeramic

The invention relates to a sound-absorbing noise-reducing ceramic assembly. The sound-absorbing noise-reducing ceramic assembly comprises at least one sound-absorbing noise-reducing ceramic unit; the sound-absorbing noise-reducing ceramic unit is multichannel cellular ceramic, and the channel inner wall of the multichannel cellular ceramic is in a porous structure. The ceramic assembly has excellent sound-absorbing and noise-reducing functions, and is suitable for sound-absorbing space indoor and outdoor, and is especially suitable for being used in outdoor sound-absorbing noise-reducing engineering such as highway, high speed railway, tunnel and subway, and the ceramic assembly has the obvious effect for absorbing sound and reducing noise, and has the advantages of convenient construction, good weatherability and environmental protection.

Owner:佛山中科产业技术研究院

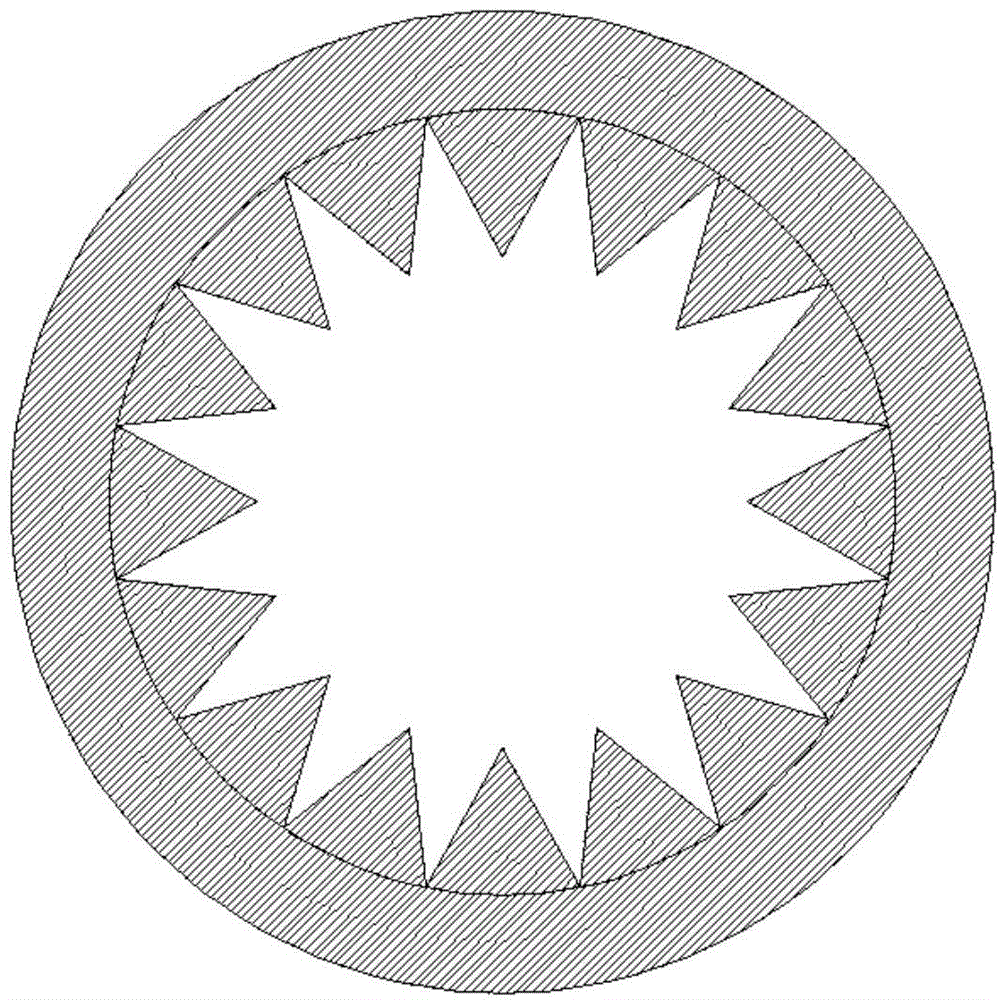

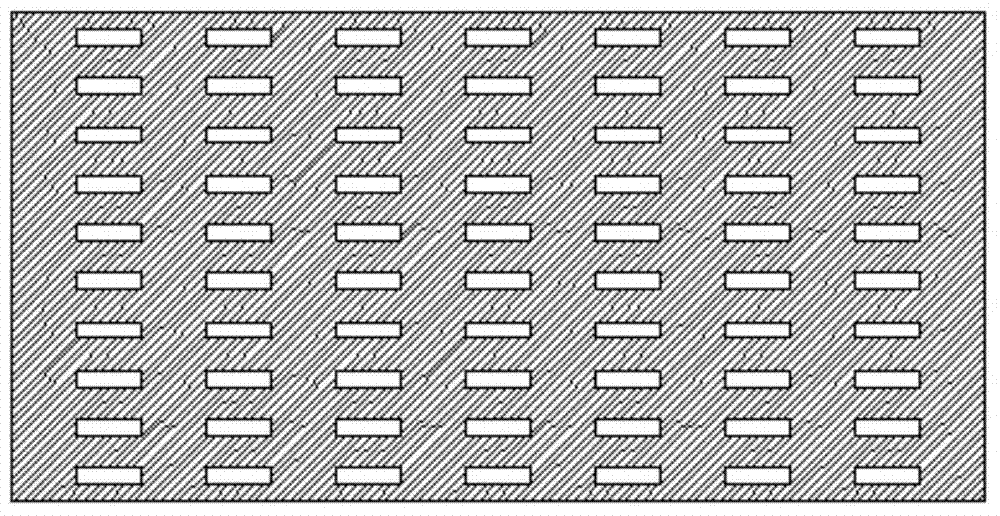

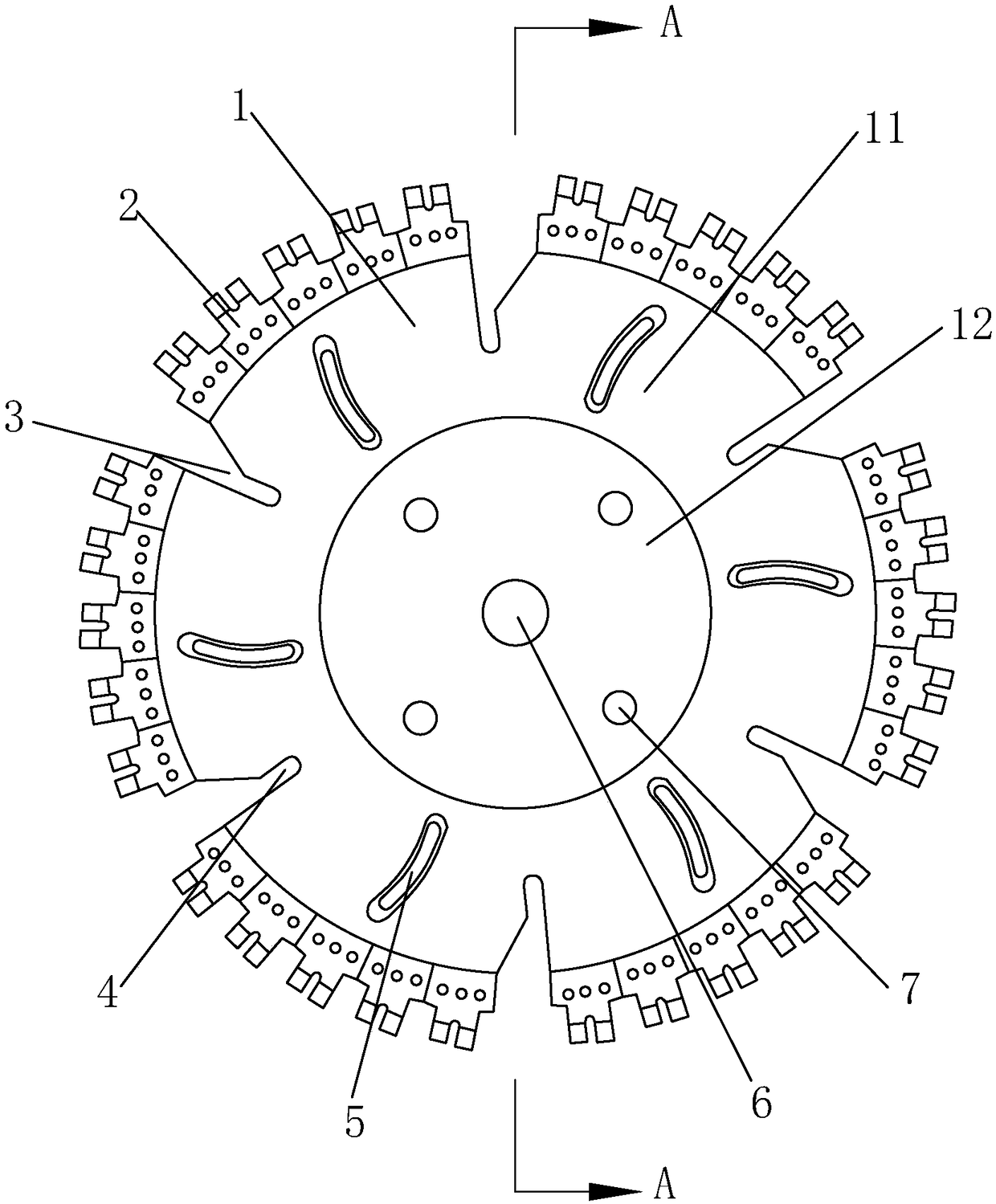

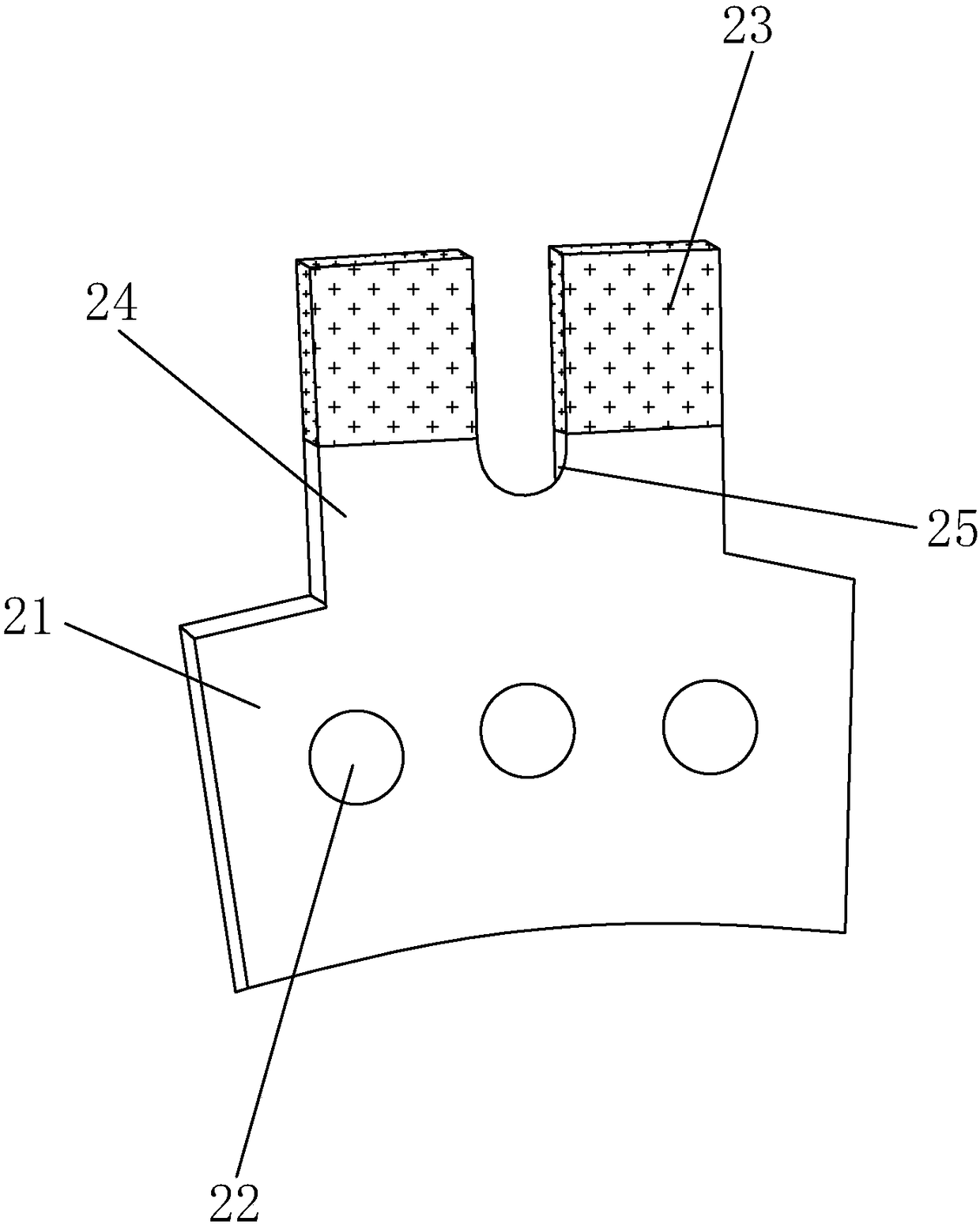

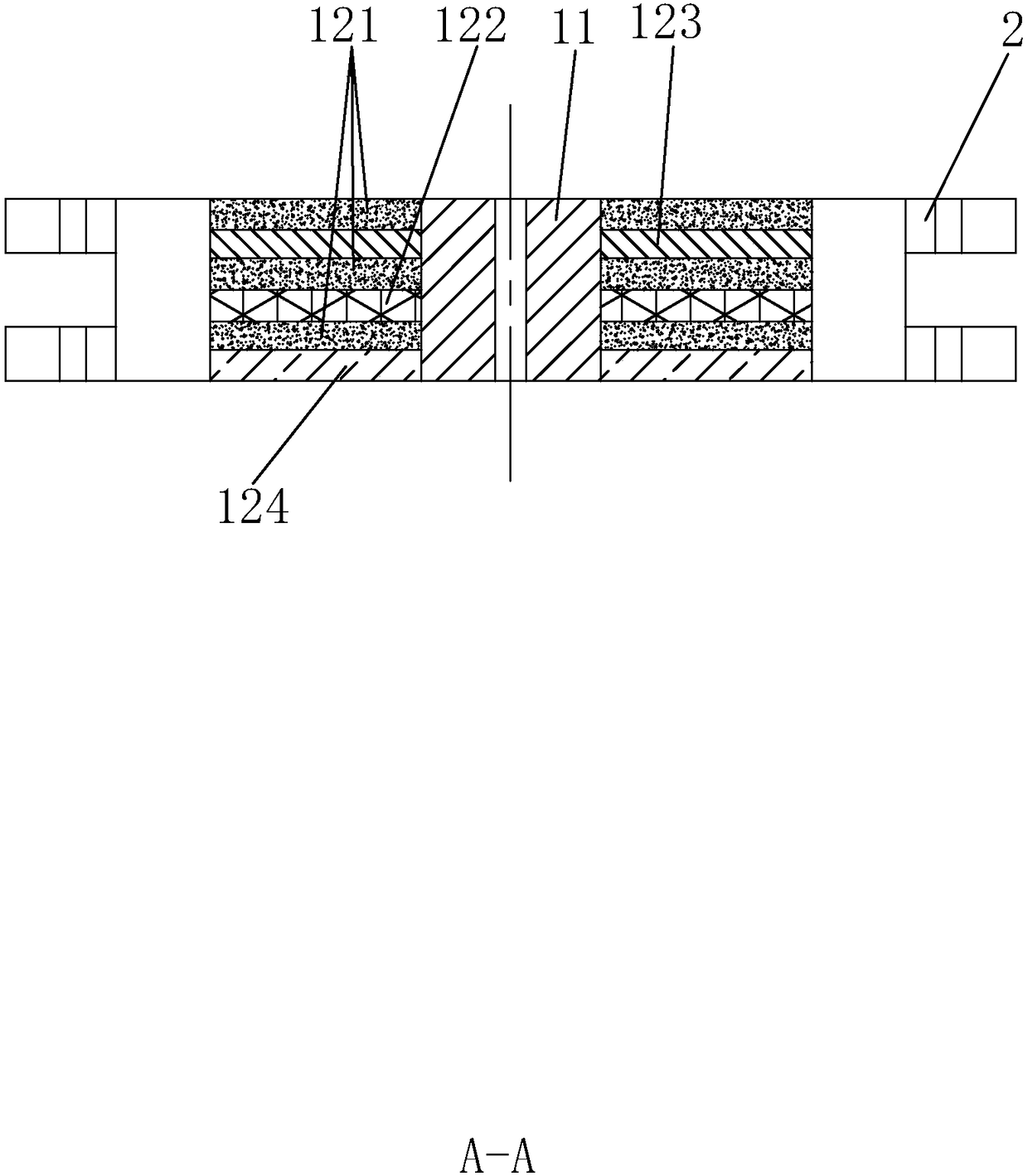

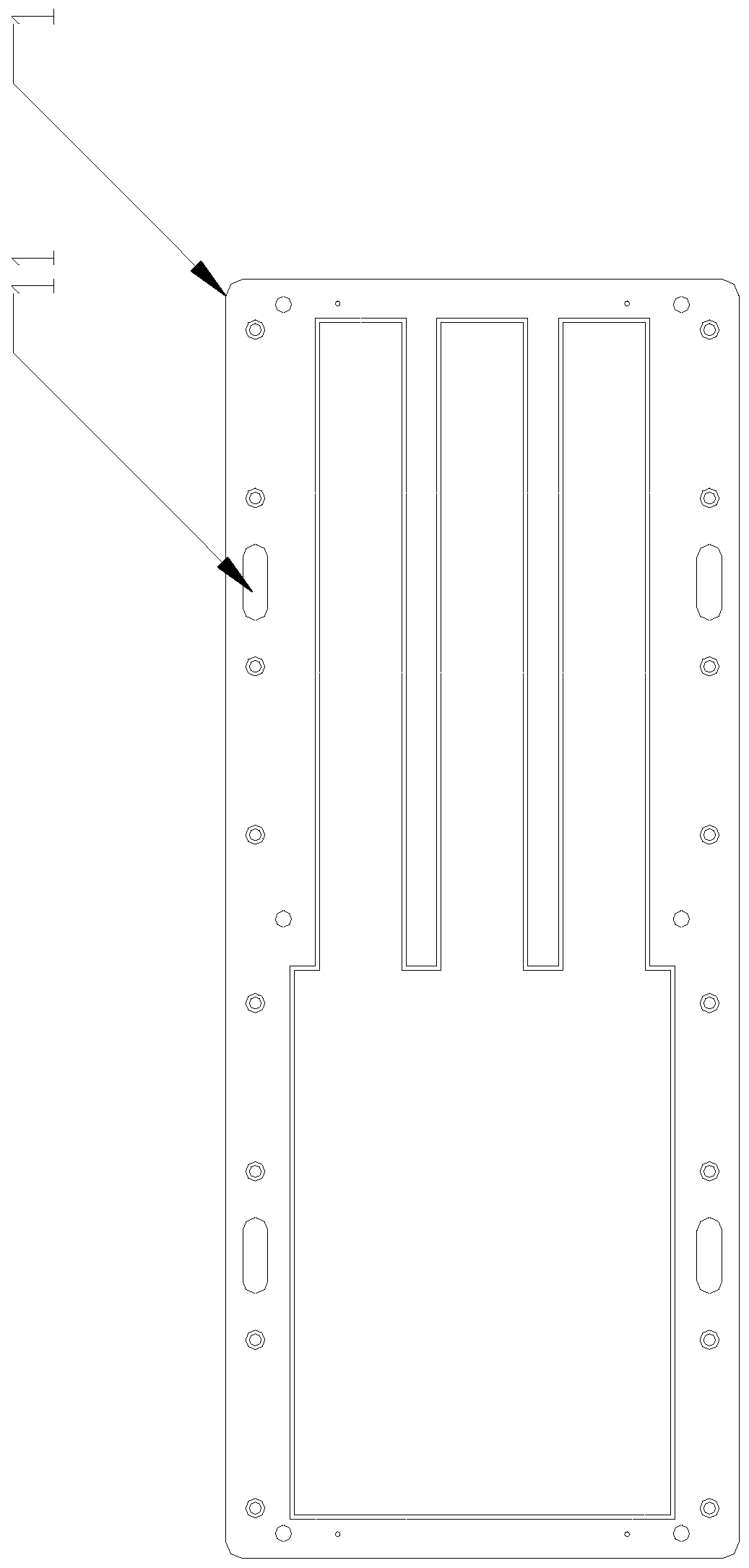

Processing Technology of Environment-friendly and Energy-saving Stone Saw Blade

ActiveCN106945183BReduce quality problemsHigh strengthStone-like material working toolsEpoxyGlass fiber

The invention provides an environmentally-friendly energy-saving stone saw blade and a machining process thereof, and relates to the field of cutting tools. In order to overcome defects in the prior art, the environmentally-friendly energy-saving stone saw blade which has the advantages that the noise is reduced through noise suppression, the deadweight is light, the energy is saved through weight reduction, the efficiency is high, the environmentally-friendly property is achieved, the structure is simple, and the operation is simple and convenient as well as the machining process of the environmentally-friendly energy-saving stone saw blade are provided. The environmentally-friendly energy-saving stone saw blade comprises a saw blade body and saw teeth which are annularly distributed on the edge of the saw blade body, wherein the saw blade body comprises a metal part and a composite part; the composite part sleeves the metal part, and comprises a carbon fiber, a glass fiber, and two or three mixtures of the carbon fiber and the glass fiber; the carbon fiber, the glass fiber, and two or three mixtures of the carbon fiber and the glass fiber are laid in a layer manner, thereby forming a carbon fiber layer, a glass fiber layer and a mixed layer; and the space between every two adjacent layers is coated with epoxy resin glue, thereby forming a bonding layer. The machining process comprises the following steps: preparing materials; laying the composite materials of the composite part; and compacting the composite part.

Owner:上海三足鼎新材料股份有限公司

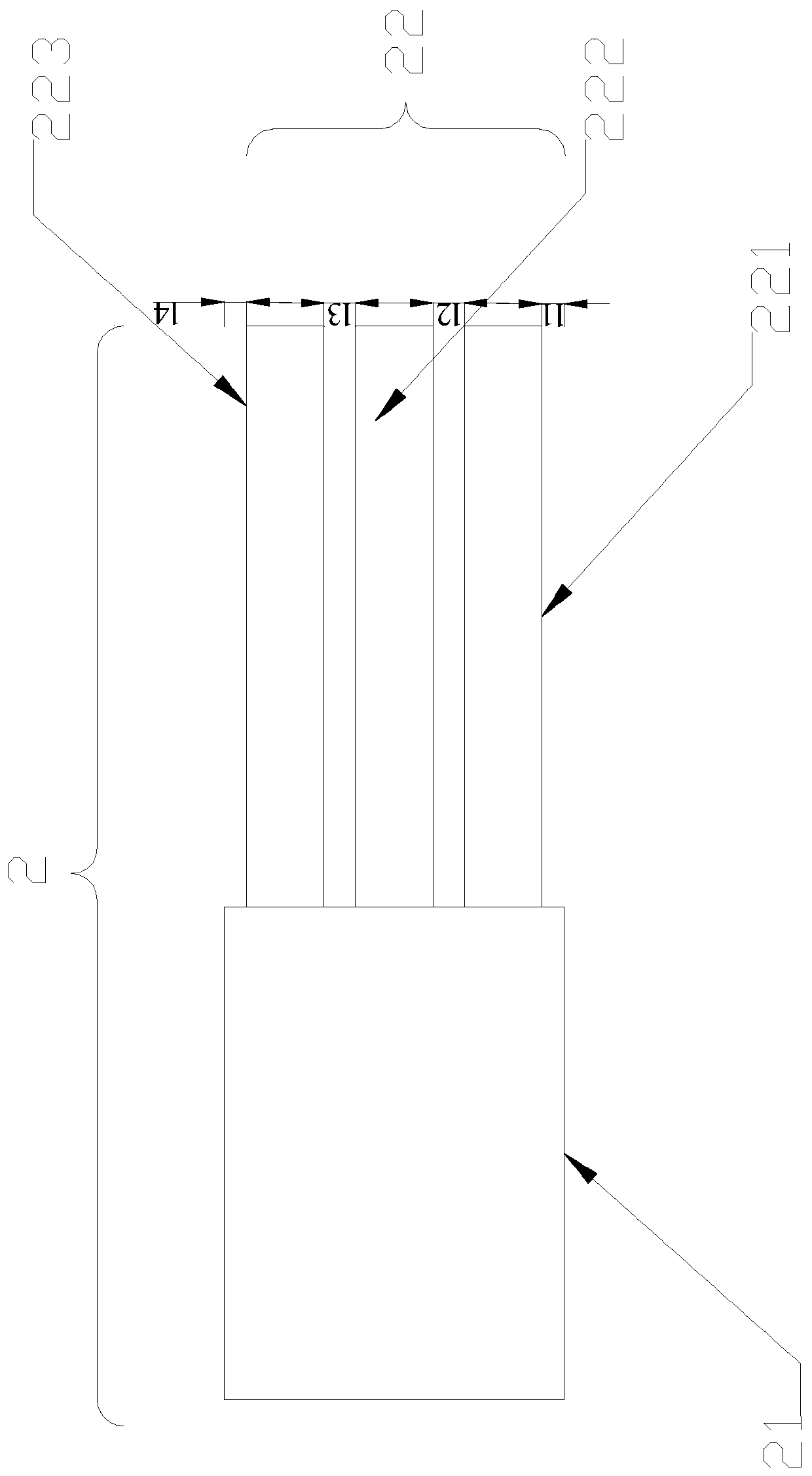

Hot pressing and forming mold of PP and PET two-component non-woven fabric sound insulation cotton

InactiveCN109878011AImproves dry sliding wear performanceIncrease dynamic elastic responseEngineeringTest material

The invention relates to a hot pressing and forming mold of PP and PET two-component non-woven fabric sound insulation cotton. The hot pressing and forming mold comprises a base, and the base is marked with a circular dividing line for mounting a sheet material; the sheet material comprises a rectangular first pressing plate and a strip-shaped second pressing plate for injecting PP and PET two-component test materials; the length of the first pressing plate is 652mm; the width of the first pressing plate is 452mm; the total length of the second pressing plate is 770mm; the width of the secondpressing plate is 422mm; the second pressing plate comprises a first limit plate, a second limit plate, and a third limit plate; the distance between the side of the first pressing plate and the sideof the first limit plate is l1, and l1 = 30 mm; the distance between the side of the first limit plate and the side of the second limit plate is l2, and l2 = 41.5 mm; the distance between the side ofthe second limit plate and the side of the third limit plate is l3, and l3 = 41.5 mm; and the distance between the side of the third limit plate and the side of the first pressing plate is l4, and l4= 30mm. The hot pressing and forming mold can reduce input of the labor cost, and greatly improve the production efficiency.

Owner:苏州壬和控股有限公司

Acoustic damping composite material and preparation method thereof

InactiveCN109338713APlay the role of noise reduction and sound absorptionImprove mechanical propertiesFibre treatmentSound proofingTextile fiberCarbon nanotube

The invention discloses an acoustic damping composite material and a preparation method thereof. The acoustic damping composite material comprises the following raw materials in parts by weight: 15 to20 parts of textile fiber, 10 to 15 parts of mixed sol, 1 to 2 parts of a surfactant, 20 to 25 parts of thermoplastic polyurethane, 10 to 15 parts of melamine, 5 to 10 parts of lignocellulose, 4 to 6parts of white carbon black, 1 to 2 parts of carbon nanotubes, 1 to 2 parts of acetyl tributyl citrate, 1 to 2 parts of boron nitride, 1 to 2 parts of hydroxypropyl starch, 1 to 2 parts of glycerinum, and 8 to 10 parts of normal octane. The acoustic damping composite material is simple in preparation technology, and cheap and available in the raw materials, avoids the use of environment-harmful lead, and is good in sound absorption and noise reduction effect.

Owner:李明珠

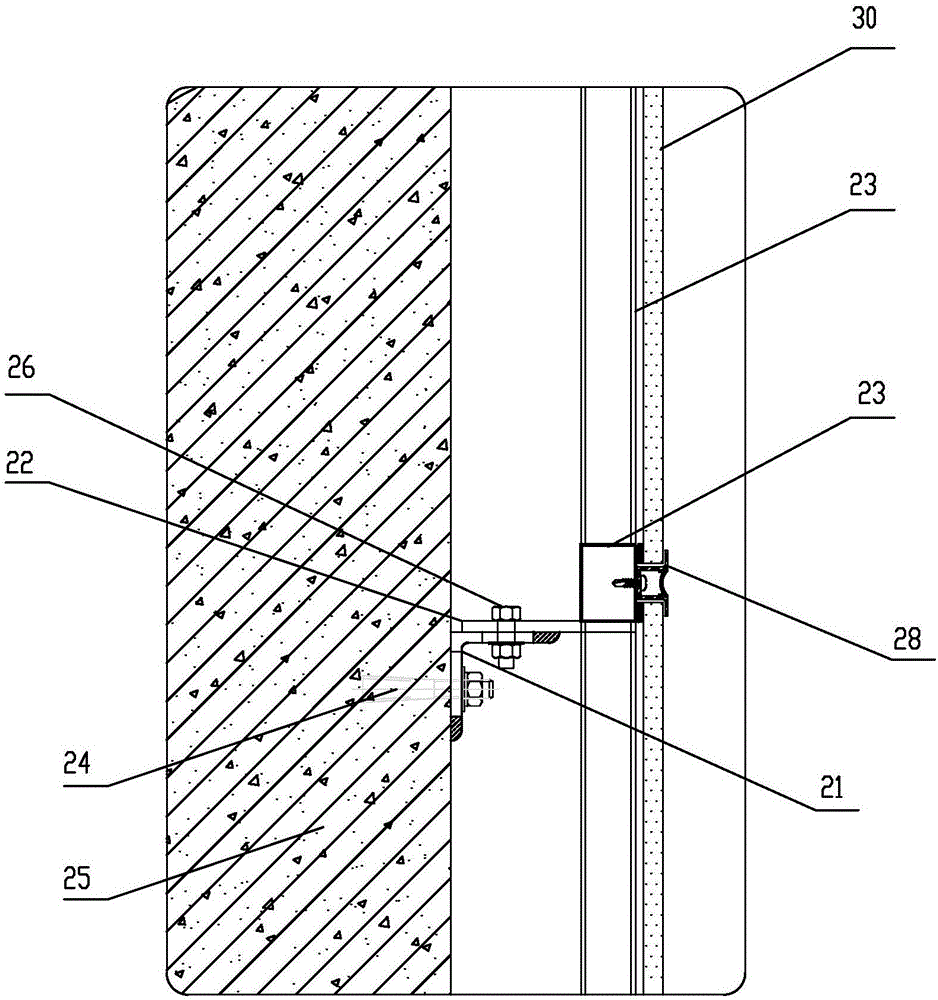

Ceiling with sound insulation and noise reduction functions

InactiveCN114232881ASimple structureSound absorption and noise reduction effect is goodCeilingsHeat proofingEngineeringMechanical engineering

The invention discloses a ceiling with sound insulation and noise reduction functions, the ceiling comprises a first plate body, a second plate body and a middle plate body located between the first plate body and the second plate body, the first plate body is fixedly connected with the middle plate body, the second plate body is fixedly connected with the middle plate body, and the second plate body is fixedly connected with the middle plate body. The first plate body is connected with an external wall body, the ceiling further comprises a first sound insulation layer, the first sound insulation layer is installed at the end, away from the middle plate body, of the second plate body, the first sound insulation layer is fixedly connected with the second plate body, and a plurality of sound absorption pads are further arranged in the first sound insulation layer; according to the ceiling with the sound insulation and noise reduction functions, the first sound insulation layer is arranged, the sound absorption pads are arranged in the internal gaps of the first sound insulation layer, the sound absorption pads absorb and reduce the noise emitted from the outside, and the ceiling is simple in structure and remarkable in sound absorption and noise reduction effect.

Owner:徐州恒仁机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com