Hot pressing and forming mold of PP and PET two-component non-woven fabric sound insulation cotton

A thermoforming, two-component technology, used in the production of sound insulation cotton, can solve the problems of poor sound absorption and heat insulation effect, low mechanical strength and hardness, large molding shrinkage rate, etc. The effect of sound absorption and noise reduction is good, and the effect of frequency dependence is increased

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

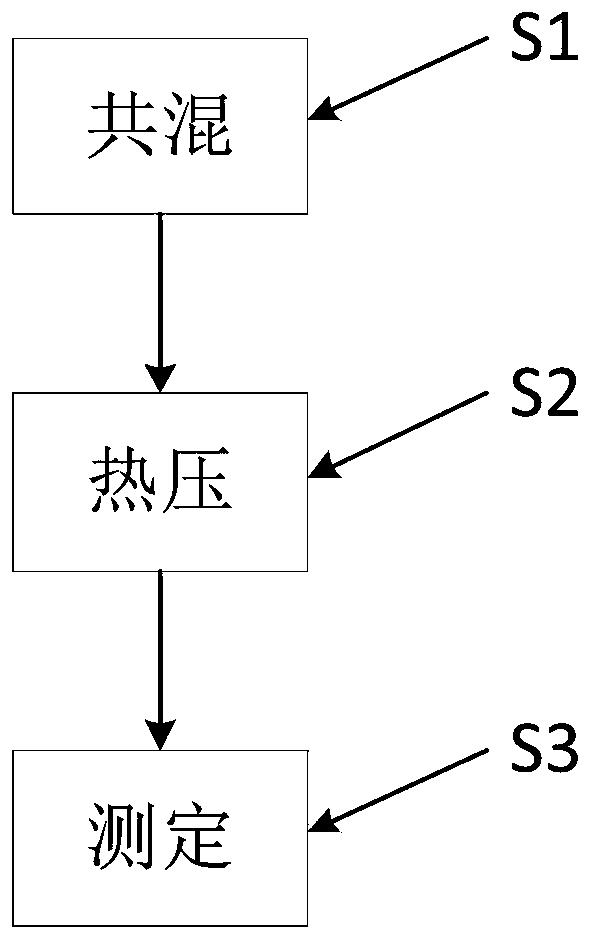

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation of this embodiment will be described below in conjunction with the accompanying drawings.

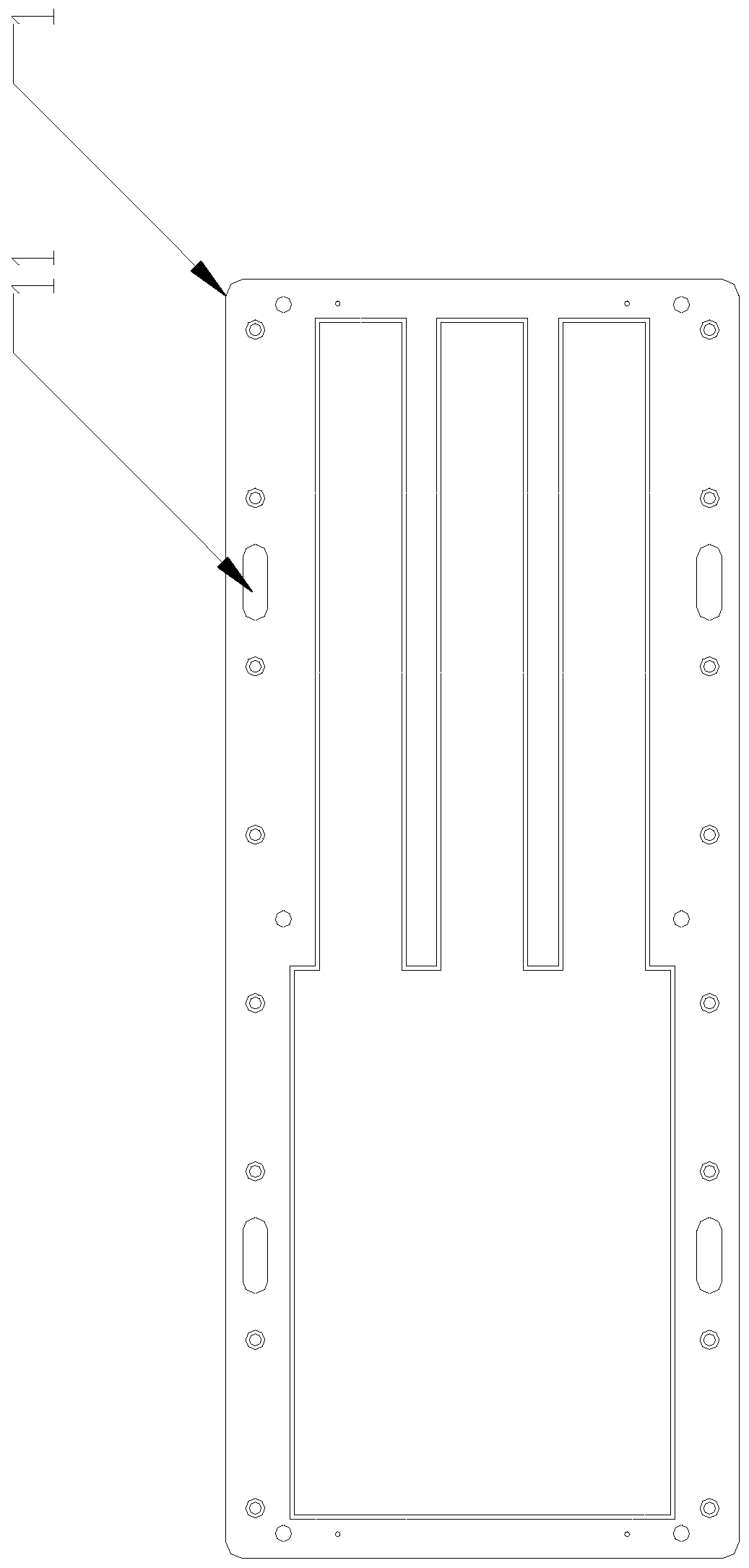

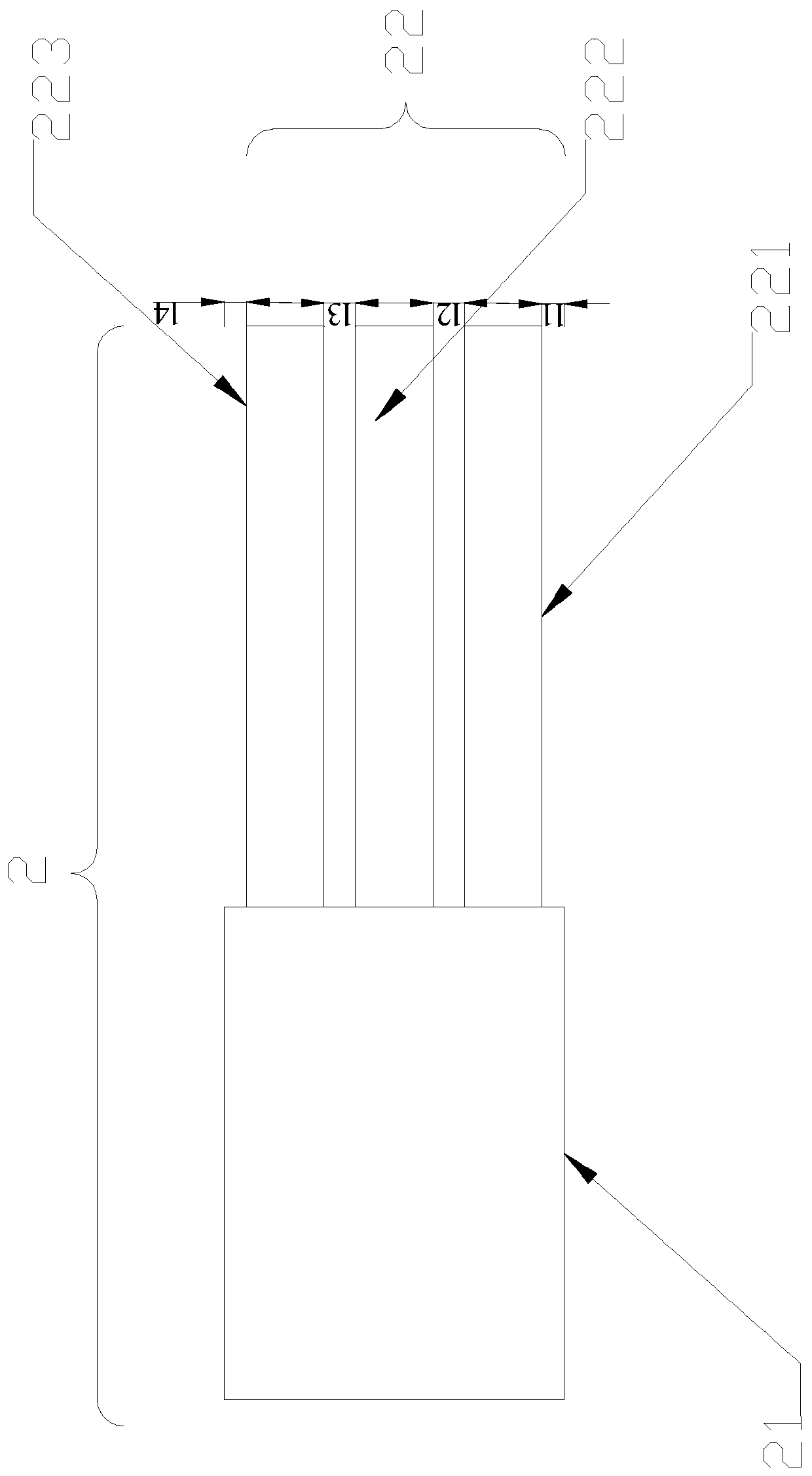

[0028] figure 1 It is a schematic diagram of the present invention, figure 2 for figure 1 Schematic diagram of the middle plate. combine figure 1 , figure 2 , a PP and PET two-component non-woven sound insulation cotton thermocompression molding mold, including a base 1. The base 1 is provided with a plurality of positioning pin holes 11 for fixing the base 1 on the fixed mold of the heat press.

[0029] The base 1 is marked with an annular dividing line for installing the plate 2 . The board 2 includes a rectangular first press plate 21 and a strip-shaped second press plate 22 for injecting PP and PET two-component samples. The thickness of the sheet 2 is 5 mm. The length of the first platen 21 is 652mm. The width of the first platen 21 is 452mm. The front side of the sample on the first pressing plate 21 is adhesive.

[0030] The total l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com