A sound-absorbing and noise-reducing ceramic component

A ceramic and component technology, applied in the field of ceramic components with sound absorption and noise reduction function, can solve the problems of unsatisfactory effect, aging, low strength, etc., and achieve the effect of remarkable sound absorption and noise reduction, good absorption capacity and good weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Weigh the raw materials according to the following proportions: plastic clay 21%, kaolin 17%, feldspar powder 33%, quartz powder 15%, sawdust powder 5%, coal gangue powder 9%, a total of 200 kg of ingredients, put it into a ball mill and water ball mill for 12 hours After that, use a mud press to dehydrate to obtain a plastic mud cake. Put the mud cake into a vacuum mud mill to practice mud to remove air bubbles in the mud and make the water in the mud uniform, improve the plasticity of the mud, and circulate the mud. After three times, the obtained mud sticks were placed in an aging room for 24 hours. If necessary, plasticizers and body enhancers can be added to the mud.

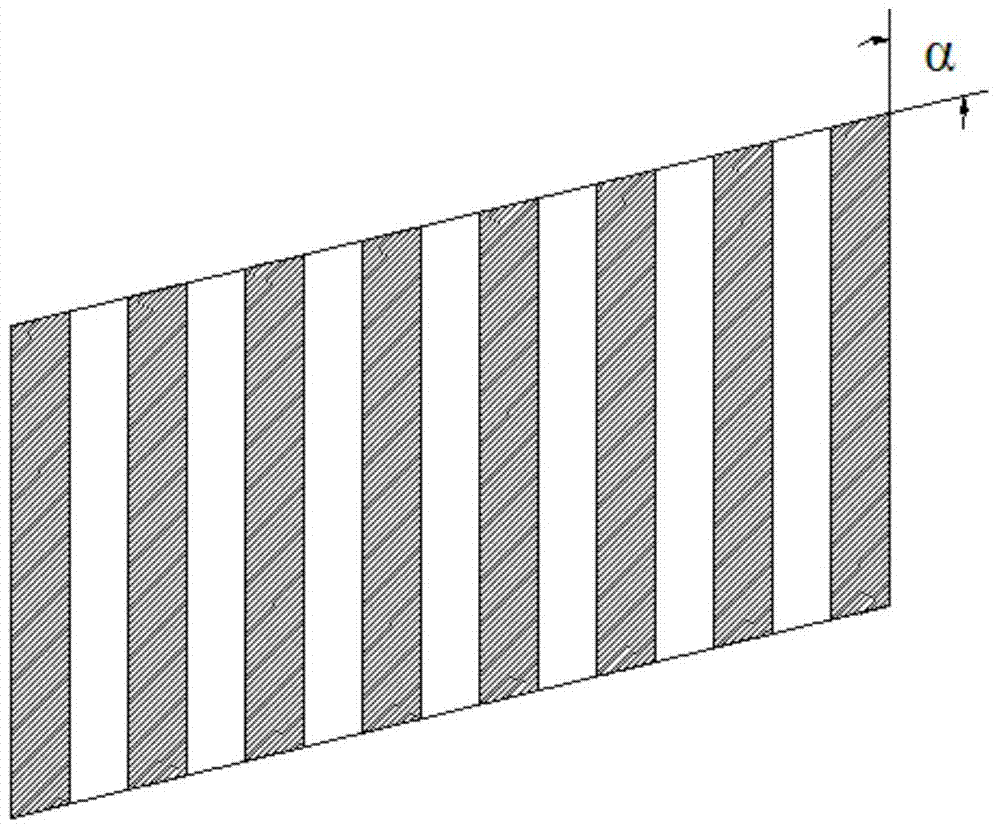

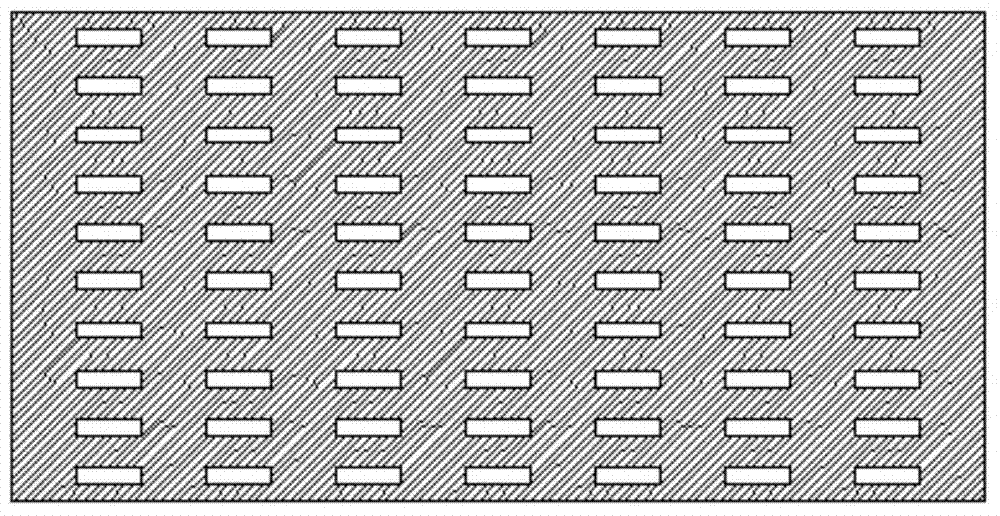

[0049] Put the stale mud sticks into a vacuum extruder, extrude the square honeycomb ceramic billet with a side length of 120 mm. The channel density in the honeycomb ceramic is 200 holes per square inch, and the channel cross-section is square. Use a cutter The ceramic blank is cut into a sound-absorb...

Embodiment 2

[0051] Weigh the raw materials according to the following proportions: plastic clay 21%, kaolin 14%, feldspar powder 23%, quartz powder 25%, carbon powder 6%, fly ash 11%, a total of 200 kg of ingredients, put it into a ball mill and water ball mill for 12 hours After that, use a mud press to dehydrate to obtain a plastic mud cake. Put the mud cake into a vacuum mud mill to practice mud, remove air bubbles in the mud and make the water in the mud uniform, improve the plasticity of the mud, and circulate the mud. After three times, the obtained mud sticks were placed in an aging room for 24 hours. If necessary, plasticizers and body enhancers can be added to the mud.

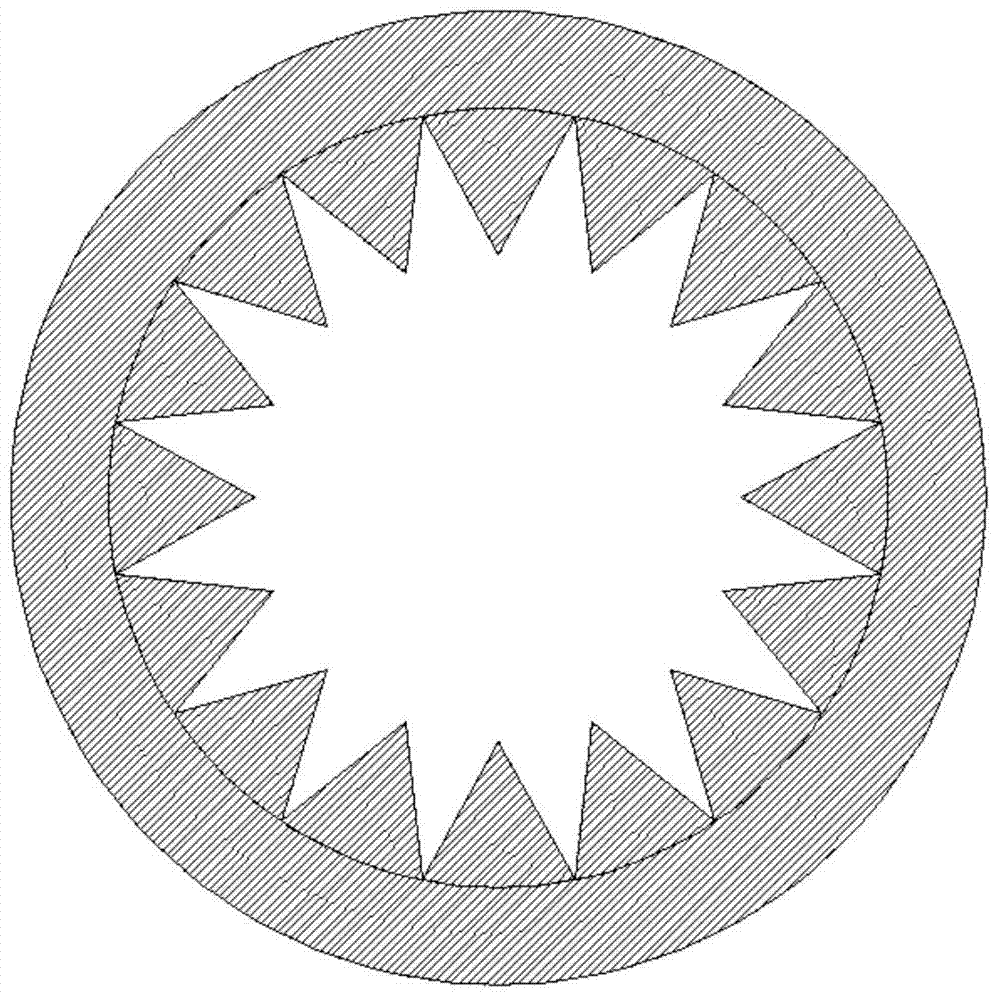

[0052] Put the stale mud sticks into a vacuum extruder to extrude a square honeycomb ceramic billet with a side length of 120 mm. The channel density in the honeycomb ceramic is 64 holes per square inch, and the channel cross-sectional shape is polygonal (such as image 3 ), use a cutter to cut the billet into a so...

Embodiment 3

[0056] Weigh the raw materials according to the following proportions: plastic clay 18%, clay 20%, feldspar powder 36%, quartz powder 20%, sawdust powder 6%, a total of 200 kilograms of ingredients, put in a ball mill and water ball mill for 12 hours, then use a mud press Dehydrate to obtain plastic mud cakes, put the mud cakes in a vacuum mud mixer to practice mud, remove the air bubbles in the mud and make the water in the mud uniform, improve the plasticity of the mud, and after three cycles of mud practice, the obtained The mud sticks are placed in the stale room for 24 hours.

[0057] Put the stale mud sticks into a vacuum extruder to extrude a rectangular honeycomb ceramic billet with a side length of 150×100 mm. The channel density in the honeycomb ceramic is 400 holes per square inch, and the channel cross-sectional shape is circular. Use a curved cutter to cut the billet into a sound-absorbing and noise-reducing honeycomb ceramic body with an angle of α=90° and a thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com