Rubber material, and preparation method and use thereof

A technology of rubber materials and natural rubber, which is applied in the field of its preparation and rubber materials, can solve problems such as poor mechanical strength, high damping coefficient, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6、 comparative example 1~2

[0092] The following table 1 is the raw material formula in each embodiment, wherein " / " indicates that this component is not added. Wherein Comparative Example 1 is a commonly used silicone rubber composition material for the tail end lug of an exhaust pipe, and Comparative Example 2 is a commonly used ethylene-propylene rubber composition material for an exhaust pipe tail end lug.

[0093] Table 1

[0094]

[0095]

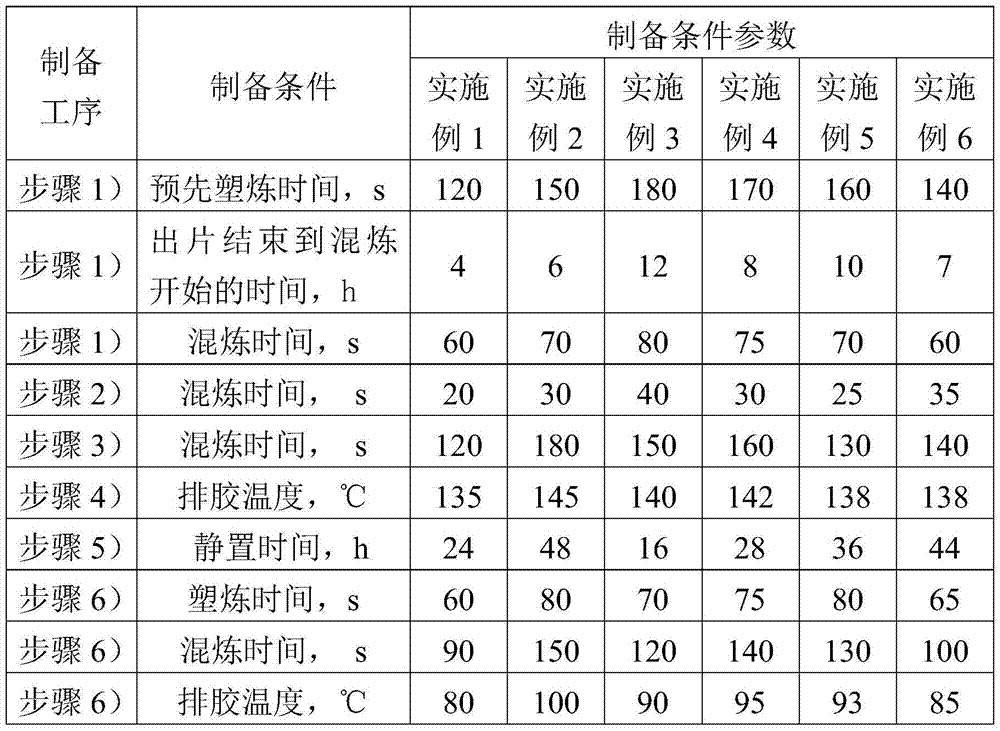

[0096] Preparation:

[0097] The following steps are prepared in conjunction with the condition parameters in Table 2;

[0098] Step 1) Pre-masticate the natural rubber with a internal mixer, and use an open mixer to produce a sheet with a thickness of 3mm, and use it within 4-12 hours; Kneading to obtain mixture A;

[0099] Step 2) Continue to put the activator zinc oxide, the stearic acid, the diaryl secondary amine anti-aging agent, the dihydroquinoline anti-aging agent, the physical anti-aging agent and the Said silane coupling agent is mixed to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com