Suspension spring for refrigeration compressor

A technology of refrigeration compressors and coil springs, applied in the direction of springs/shock absorbers, coil springs, mechanical equipment, etc., can solve the problems of hitting the shell, low spring stiffness, sudden movement, etc., and achieve the effect of reducing dynamic stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

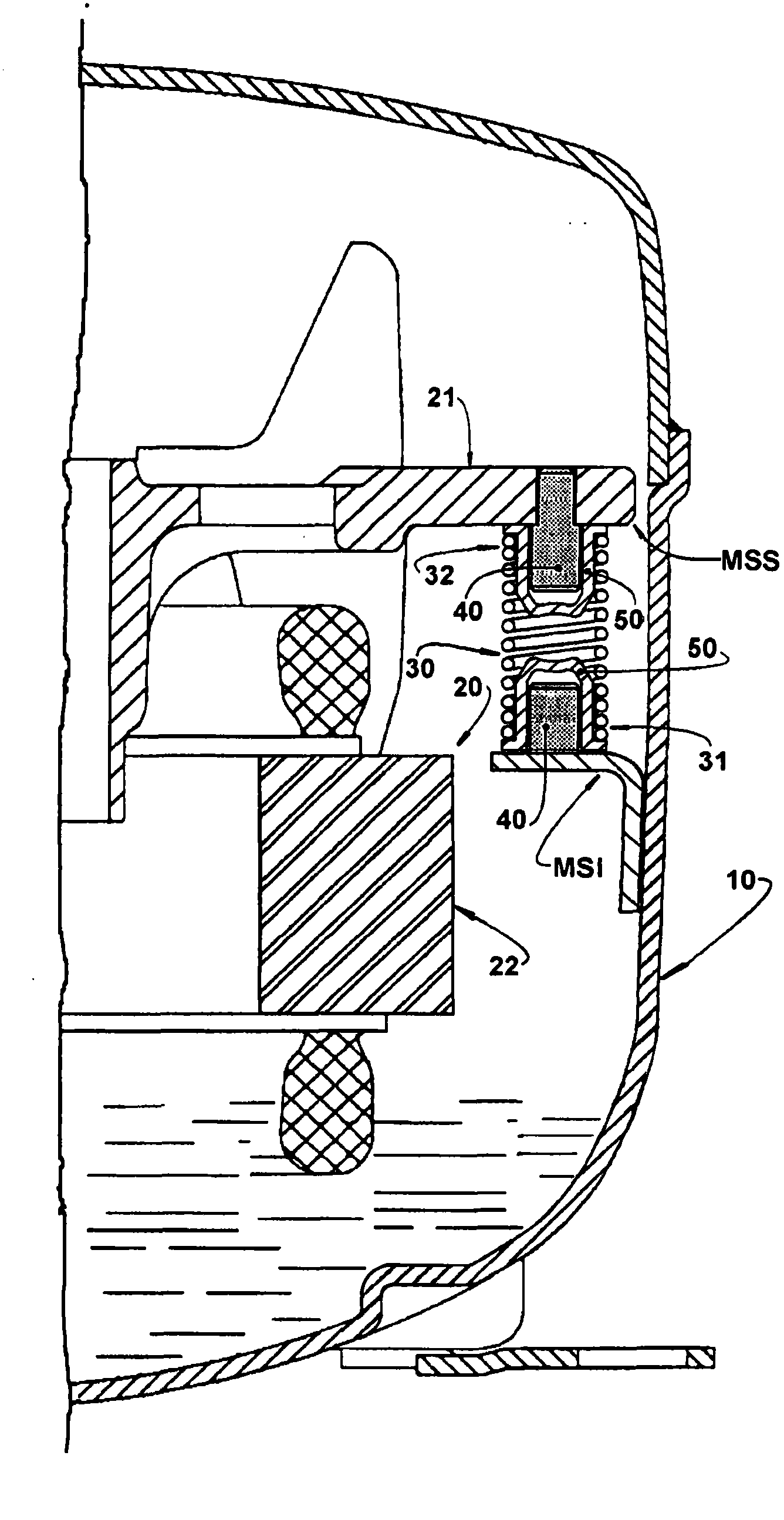

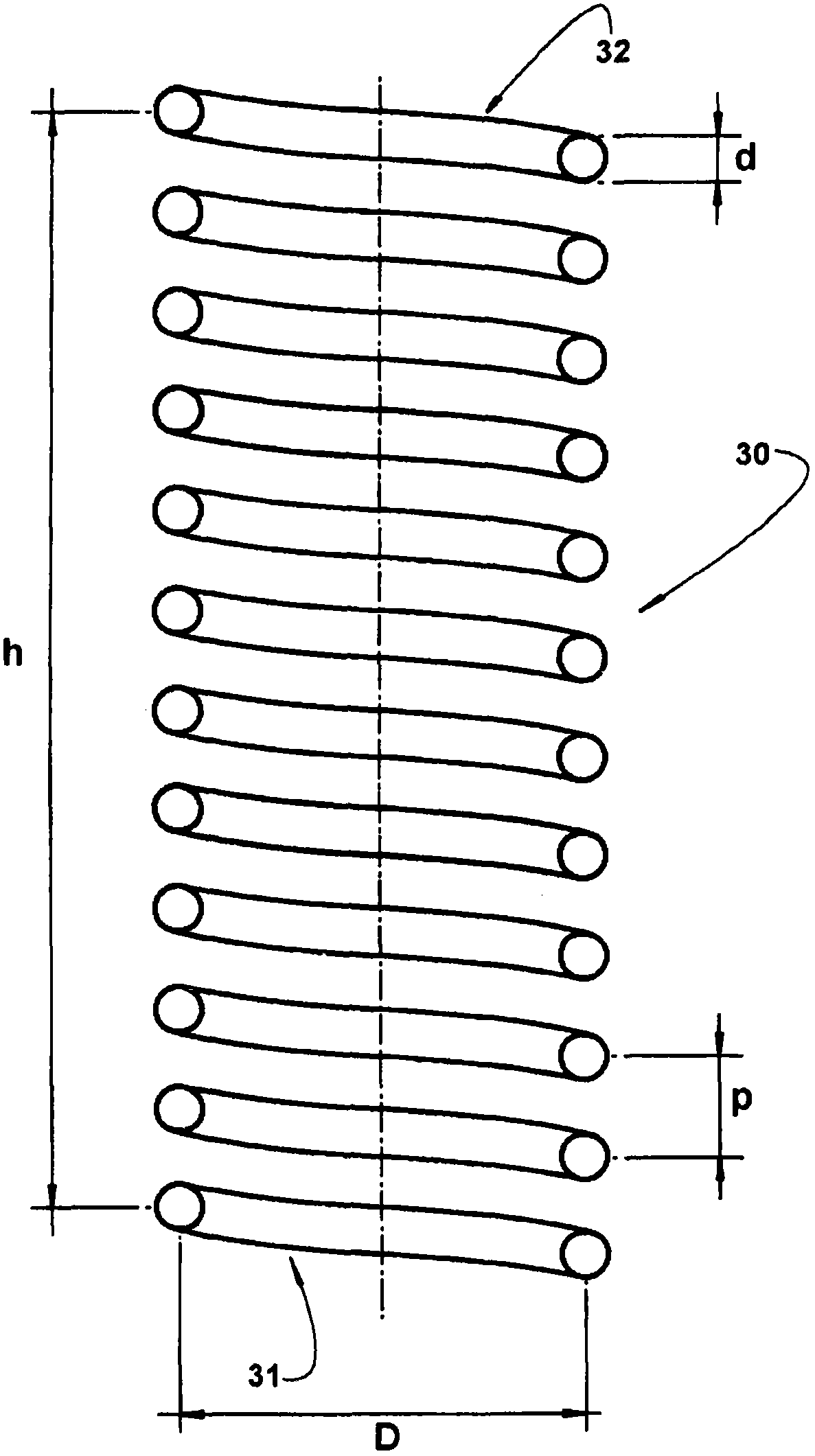

[0026] As previously described and illustrated, the helical spring obtained according to the present invention is applied to a refrigeration compressor of the vertical shaft type, as shown in Figure 1, which includes a fixed assembly 20 formed by a block 21, the stator 22 of the electric motor of the compressor is fixed Attached to block 21. The fixing assembly 20 is mounted inside the housing 10 by means of a suspension system comprising helical springs 30 operating in compression, each spring having a lower end 31 and an upper end 32, only one of which is shown in FIG. a spring. A lower end 31 and an upper end 32 of the coil spring are coupled to adjacent portions of the housing 10 and the fixing assembly 20, respectively.

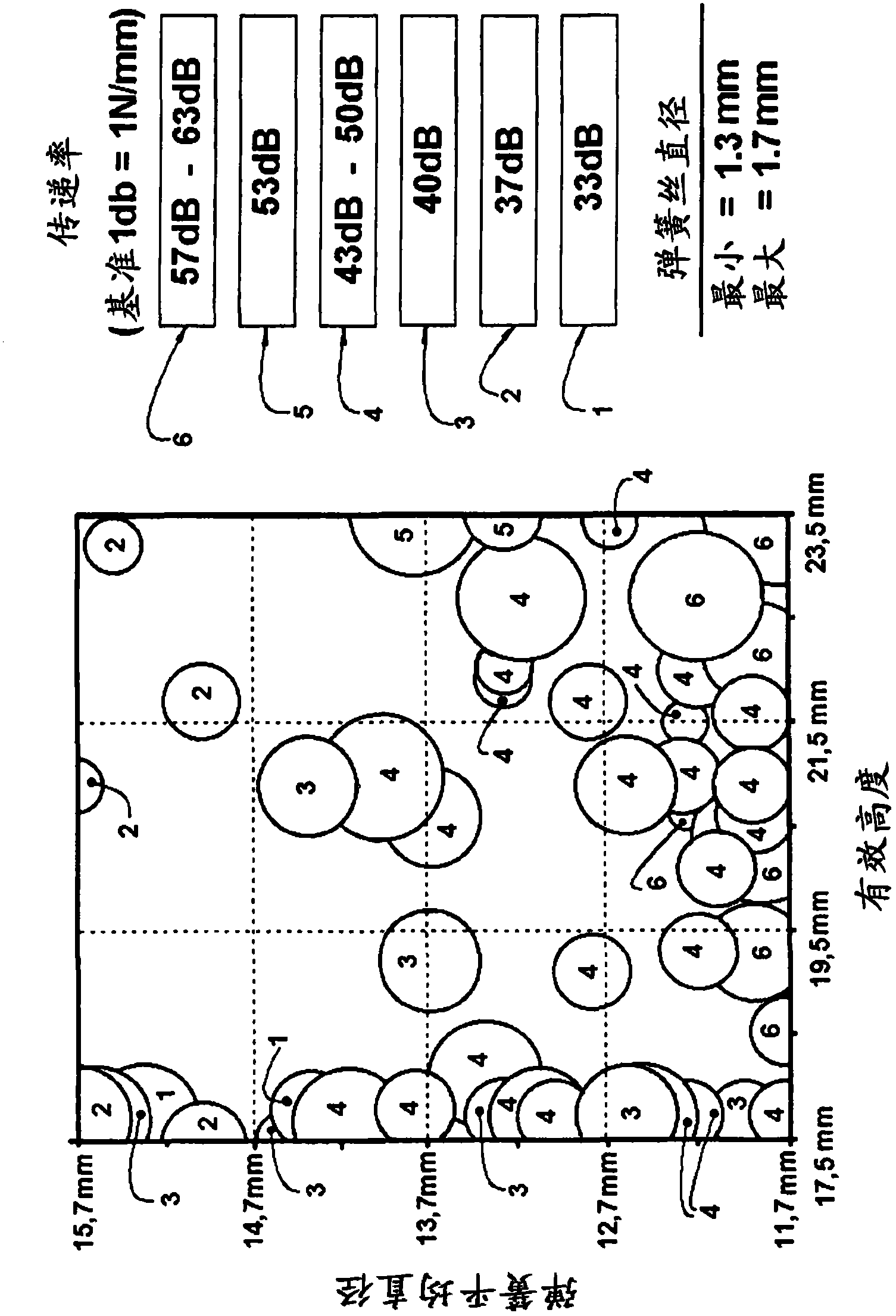

[0027] According to the present invention, for a predetermined size range of one of the spring parameters defined by the spring average diameter D, coil pitch p, spring wire diameter and spring effective height h, in each pair of parameters of the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com