Method and device for liquefying natural gas via refrigeration of single mixed refrigerant

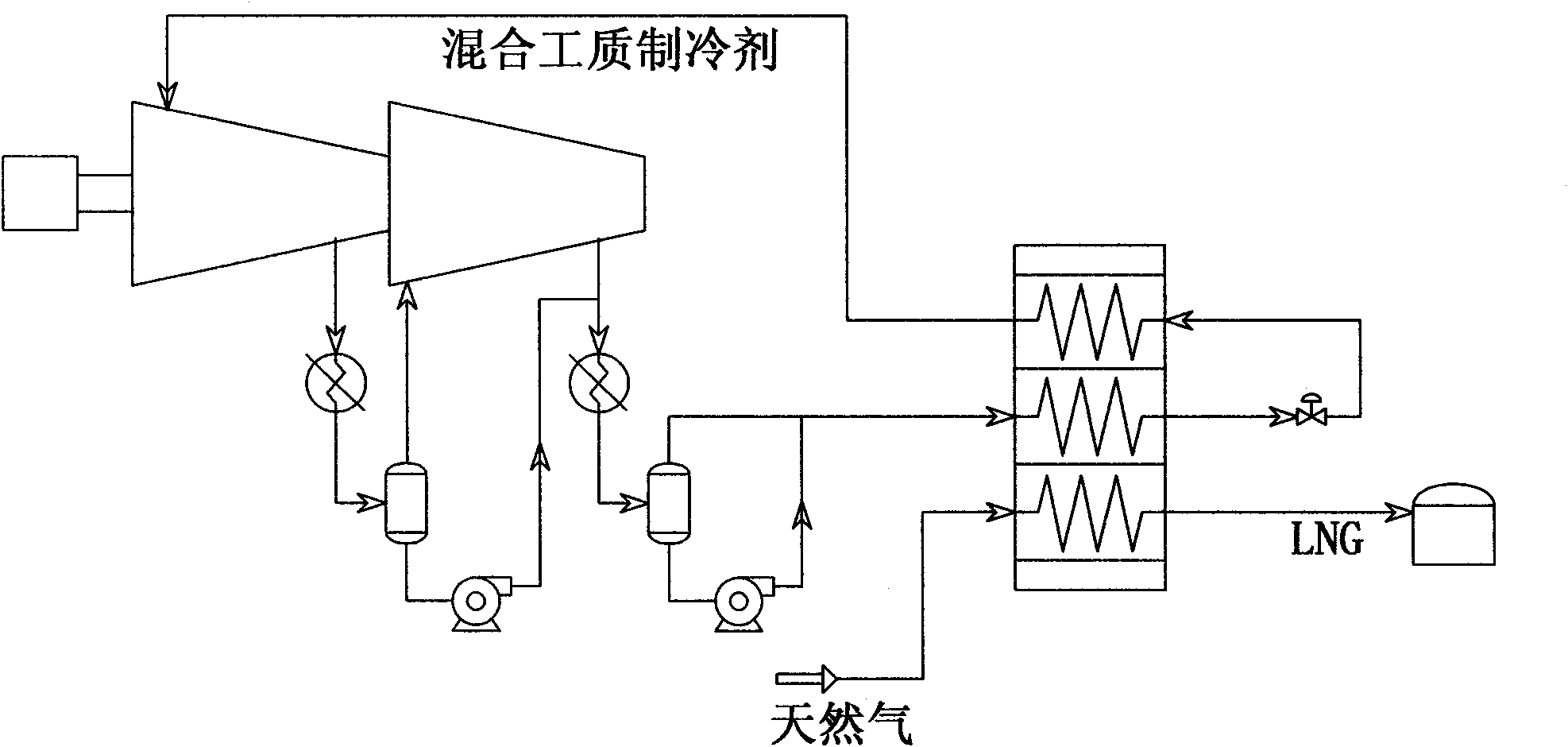

A technology of liquefied natural gas and mixed working fluid, which is applied in refrigeration and liquefaction, liquefaction, refrigerator and other directions, can solve the problems of high energy consumption of the device and poor adaptability to variable load operation, so as to reduce power consumption and increase equipment investment. , the effect of reducing the degree of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

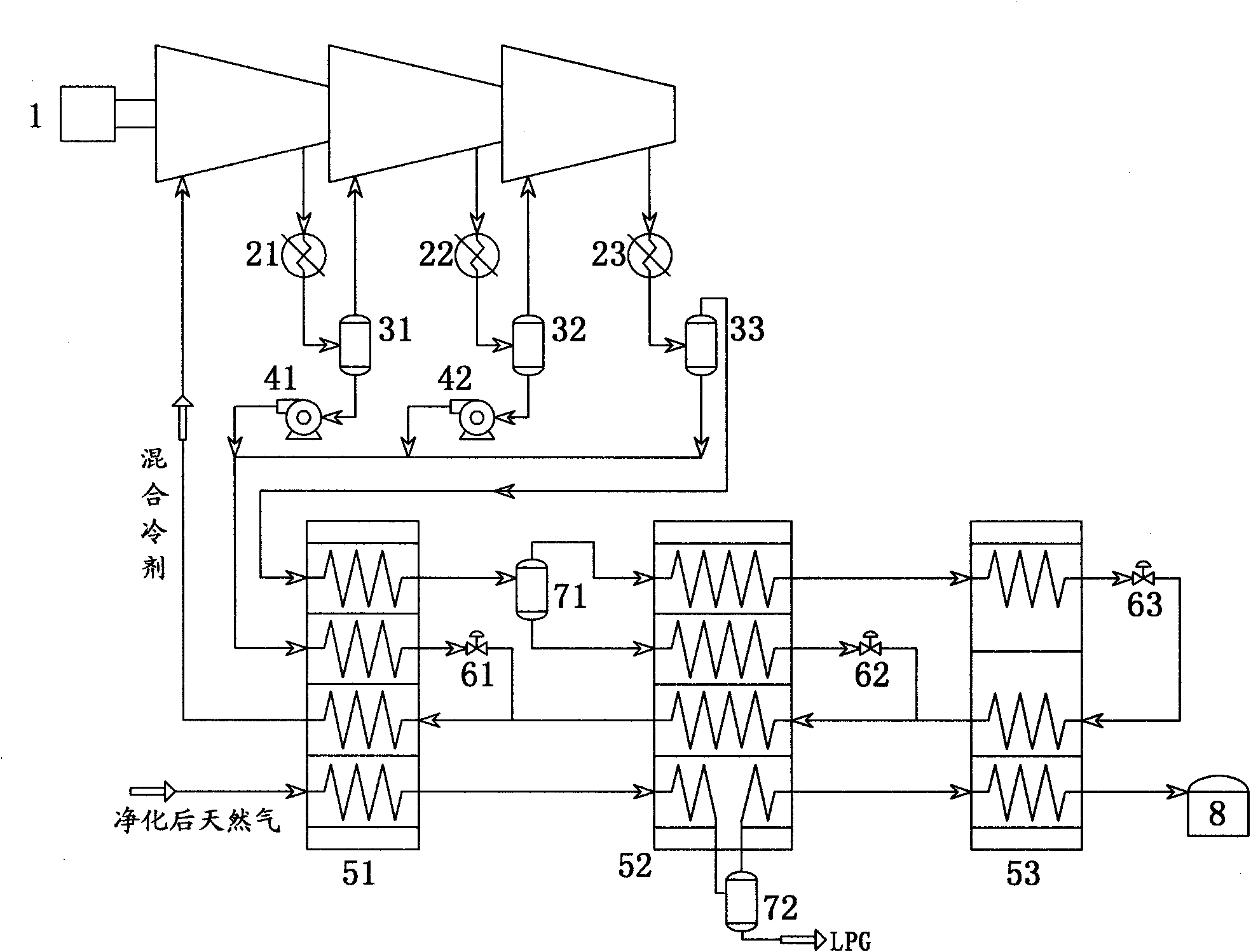

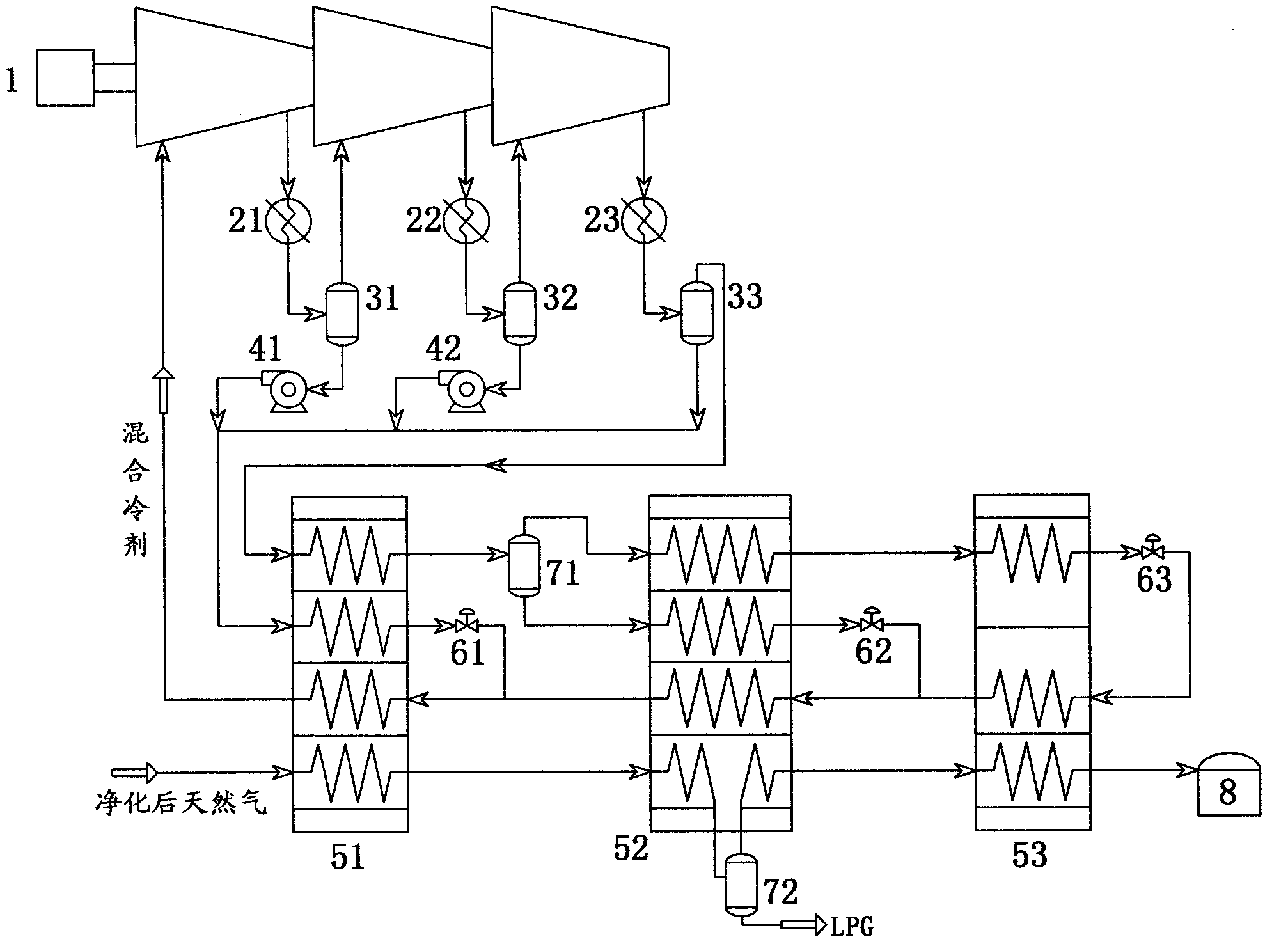

[0028] Further explain below in conjunction with accompanying drawing:

[0029] Such as figure 2 As shown, the purified raw natural gas first enters the first-stage plate-fin heat exchanger 51 and is pre-cooled to -20 to -40°C; then continues to enter the second-stage plate-fin heat exchanger 52 and is cooled to -50 to After -60°C, it enters the heavy hydrocarbon separator 72 for gas-liquid separation, and the gas phase stream separated from the top of the heavy hydrocarbon separator 72 continues to enter the secondary heat exchanger 52 until it is cooled to -80~-100°C; stage plate-fin heat exchanger 53, in which it is subcooled to -145~-165°C, and the subcooled liquefied natural gas stream is throttled by the throttle valve 63 to obtain LNG products, and sent to the LNG storage tank 8 store.

[0030] Mixed refrigerant cycle:

[0031] The mixed working medium composed of C1~C5 and N2 enters the inlet of compressor 1 after a reasonable ratio, is compressed to 0.6~1MPa for a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com