Composite conical rubber spring and rigidity design method thereof

A rubber spring and conical technology, which is applied in the field of composite conical rubber spring and its stiffness design, can solve the problems of limited space of conical spring, increased structural burden of the frame, high sealing performance of the built-in airbag, etc., and achieves vertical stiffness improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

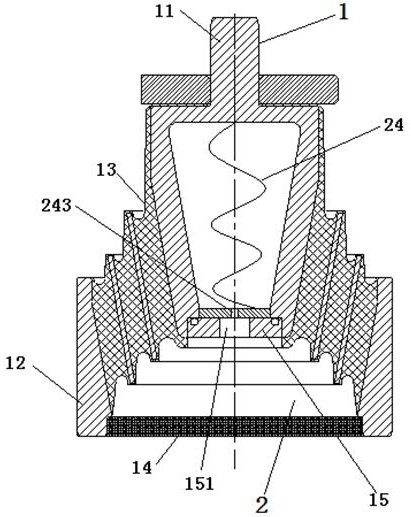

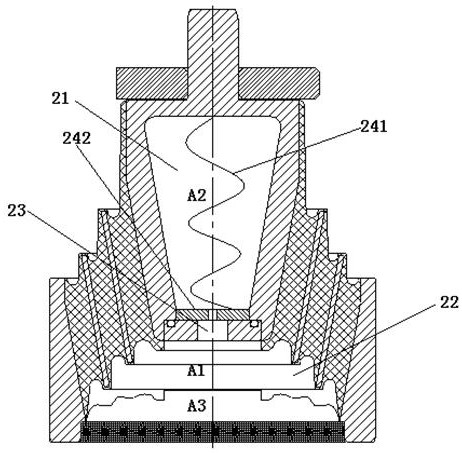

[0022] Combine below Figure 1~2 The embodiments of the present invention will be described in detail.

[0023] The composite conical rubber spring includes a conical rubber spring 1, which is characterized in that: the hydraulic damping mechanism 2 is sealed in the conical rubber spring 1, and the hydraulic damping mechanism 2 generates dynamic pressure with the vertical load of the conical rubber spring 1. Damping, providing dynamic stiffness to conical rubber spring 1.

[0024] The above-mentioned composite conical rubber spring is provided with a hydraulic damping mechanism 2 in the conical rubber spring 1 , and this design can give full play to the elastic support function of the rubber body in the conical rubber spring 1 and the dynamic hardening effect of the hydraulic damping mechanism 2 . When the rail vehicle crosses the curve at low speed, the excitation frequency of the composite conical rubber spring is low. At this time, the elastic support of the rubber body it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com