Rubber material for liner bushing of track-laying vehicle

A rubber material and vehicle technology, applied in the field of hydrogenated nitrile rubber materials, can solve problems such as the difficulty in meeting the requirements for the use of crawler-type special vehicle bushings, achieve low compression set, highlight flex resistance, and reduce compression set Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The components and detection results of embodiment one are as shown in table 1 and table 2:

[0044] Table 1

[0045] Raw materials and specifications

Based on 100 parts of rubber

HNBR

100

ZnO

5

1

N330

10

N550

15

Silica

5

ZDMA

0,5,10,15

4010NA

1

TMQ

1

CZ

0.5

DTDM

0.5

1

BIBP

1.5

HVA-2

1

DOS

5

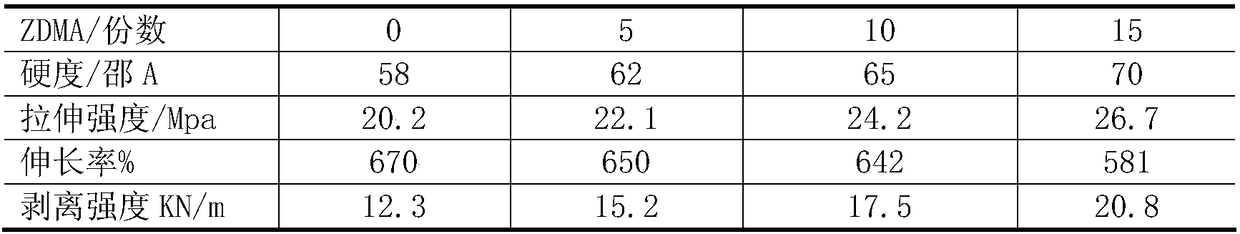

[0046] Table 2

[0047]

[0048] It can be seen from Table 2 that as the ZDMA content increases, the peel strength and tensile strength also increase.

Embodiment 2

[0049] Components and detection results of embodiment two are as shown in table 3 and table 4:

[0050] table 3

[0051] Raw materials and specifications

Based on 100 parts of rubber

HNBR

100

ZnO

5

1

N330

10

N550

12

Silica

5

ZDMA

10

4010NA

1

TMQ

1

CZ

0.5

DTDM

0.5

1

BIBP

1.5,3,4.5

HVA-2

1

DOS

3

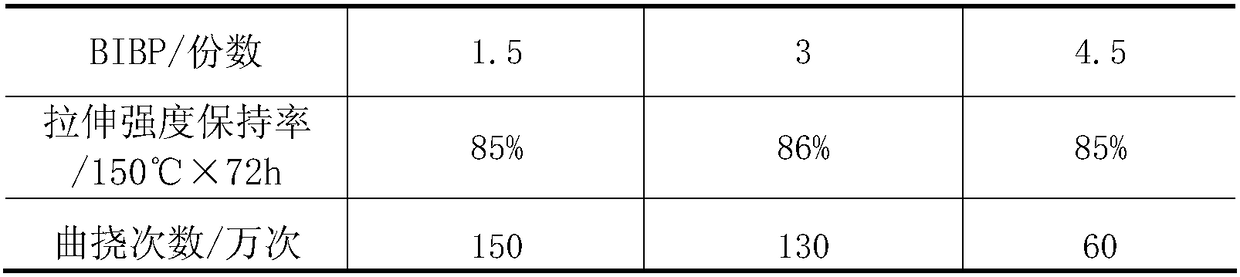

[0052] Table 4

[0053]

[0054] The flex test is Demecia type.

[0055] It can be seen from Table 4 that the number of flexures decreases with the increase of BIBP content. After 150℃×72h hot air aging, there is still a tensile strength retention rate of more than 85%, and it has excellent aging resistance.

[0056] Based on the above experimental results, in order to achieve the purpose of the present invention and meet the requirements for use of special tracked vehicle bushings, the hardness i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com