Run flat tyre sidewall supporting rubber and a preparing method thereof

A run-flat tire and support rubber technology, which is applied in the field of tires, can solve problems such as unstable performance, and achieve high modulus, improved heat aging resistance, and excellent heat aging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The run-flat tire sidewall support rubber includes raw materials with the following weights:

[0028] Natural rubber STR20#30Kg, butadiene rubber BR9000 40Kg, butadiene rubber VCR412 30Kg; carbon black N550 25Kg, white carbon black 20Kg, silane coupling agent 2Kg, indirect method zinc oxide 5Kg, stearic acid 1Kg, anti-aging agent RD 1Kg, anti-aging Agent 4020 2Kg, tert-butylphenol alkyne resin 2Kg, insoluble sulfur 7020 2.5Kg, CZ accelerator 4.25Kg, 4,4`-dimorpholine disulfide 2.0Kg, anti-reversion agent 2Kg, anti-scorch agent CTP 0.15Kg.

[0029] The preparation method of this run-flat tire side support rubber, comprises the steps:

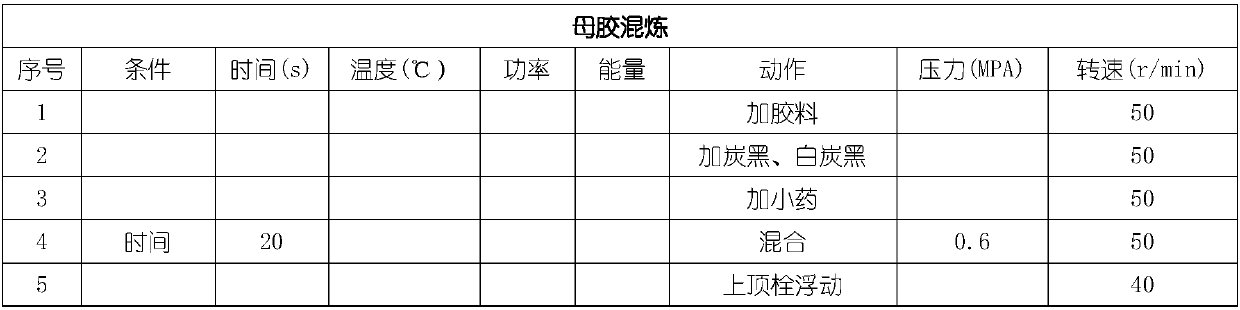

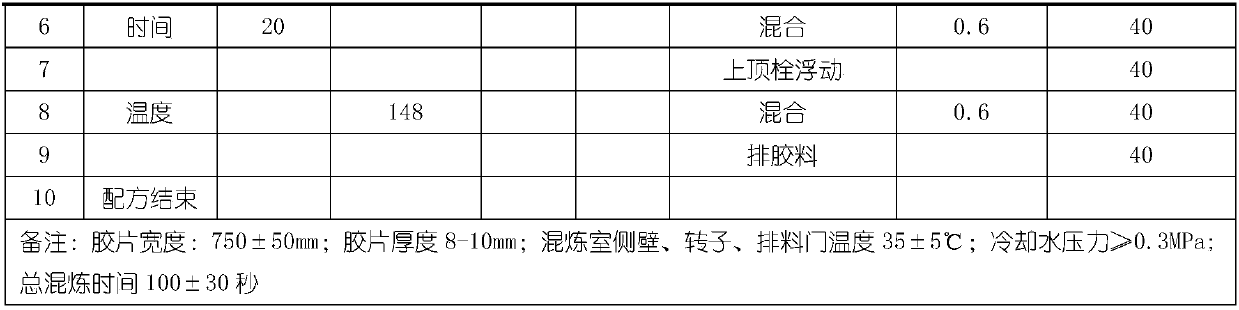

[0030] (1) Masterbatch mixing

[0031] Take the natural rubber SMR20# of the above weight, butadiene rubber BR9000, butadiene rubber VCR412, carbon black N550, white carbon black, silane coupling agent, indirect zinc oxide, stearic acid, anti-aging agent, tert-butylphenol alkyne resin Put it into the XM370 internal mixer, press the top b...

Embodiment 2

[0045] The run-flat tire sidewall support rubber includes raw materials with the following weights:

[0046] Natural rubber STR20#25Kg, butadiene rubber BR9000 45Kg, butadiene rubber VCR412 30Kg; carbon black N550 20Kg, white carbon black 15Kg, silane coupling agent 1.5Kg, indirect zinc oxide 4Kg, stearic acid 0.5Kg, antioxidant RD 0.5 Kg, anti-aging agent 4020 1.5Kg, tert-butylphenol alkyne resin 1.5Kg, insoluble sulfur 7020 2.4Kg, CZ accelerator 4Kg, 4,4`-dimorpholine disulfide 2.2Kg, anti-reversion agent 1.9Kg, anti-scorch Agent CTP 0.1Kg.

[0047] The preparation method of the run-flat tire sidewall support rubber is the same as in Example 1, and will not be described in detail here.

Embodiment 3

[0049] The run-flat tire sidewall support rubber includes raw materials with the following weights:

[0050]Natural rubber STR20#35Kg, butadiene rubber BR9000 35Kg, butadiene rubber VCR412 30Kg; carbon black N550 30Kg, white carbon black 25Kg, silane coupling agent 2.5Kg, indirect zinc oxide 6Kg, stearic acid 1.5Kg, antioxidant RD 1.5 Kg, anti-aging agent 4020 2.5Kg, tert-butylphenol alkyne resin 2.5Kg, insoluble sulfur 7020 2.6Kg, CZ accelerator 4.5Kg, 4,4`-dimorpholine disulfide 2.0Kg anti-reversion agent 2.1Kg, anti-scorch Agent CTP 0.2Kg.

[0051] The preparation method of the run-flat tire sidewall support rubber is the same as in Example 1, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com