High-dispersity white carbon black and preparation method thereof

A white carbon black, mass fraction technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as poor processing performance and poor dispersion performance, and achieve the effect of improving dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

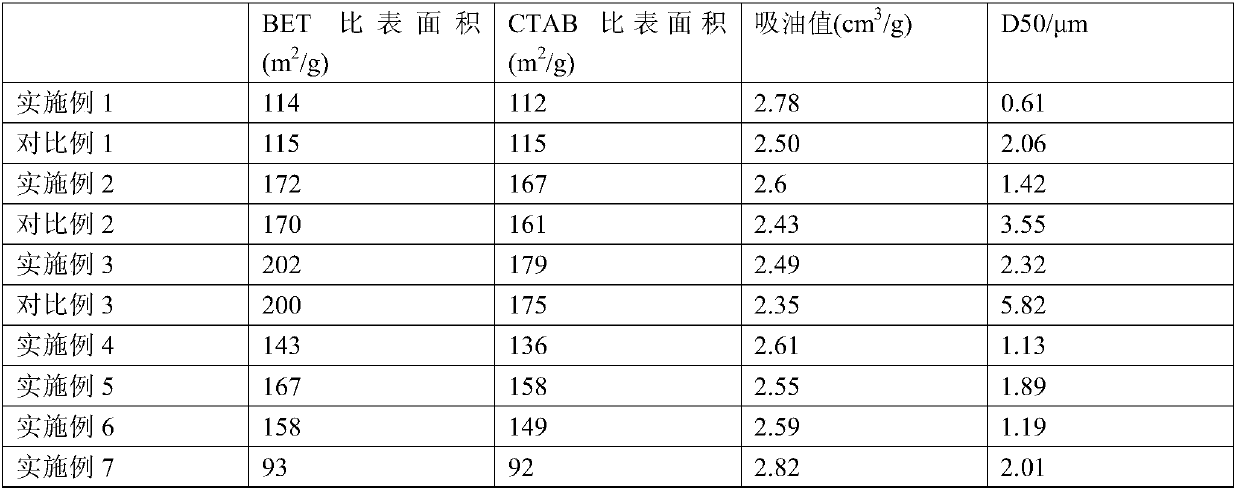

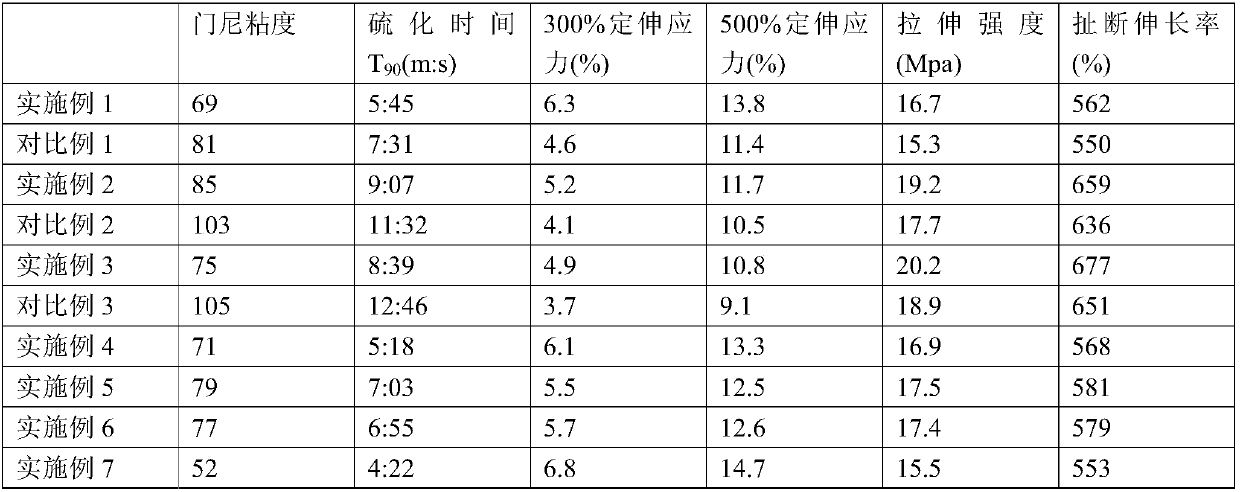

Examples

Embodiment 1

[0061] The present embodiment provides a kind of method for preparing white carbon black, and its specific method is:

[0062] (1) Preparation of reaction bottom liquid: add water to the reaction kettle, use oil bath heating to control the temperature of water at 88°C, add a certain amount of water glass solution, prepare a reaction bottom liquid with a water glass concentration of 0.09mol / L, and then Add the dehydrated alcohol of 0.7% (accounting for the percentage of reaction bottom liquid mass) wherein, stir evenly, and keep its temperature constant at 88 ℃, wherein, the water glass total amount that uses in the described precipitation reaction includes consumption in the preparation of bottom liquid amount.

[0063] (2) Reaction stage: in the reaction bottom liquid of step (1), add the concentrated sulfuric acid and water glass solution simultaneously, carry out reaction, keep stirring during; Wherein, in the whole reaction stage, reaction temperature remains constant, and...

Embodiment 2

[0075] The present embodiment provides a kind of method for preparing white carbon black, and its specific method is:

[0076] (1) Preparation of reaction bottom liquid: add water to the reaction kettle, use oil bath heating to control the temperature of water at 80°C, add a certain amount of water glass solution, prepare a reaction bottom liquid with a water glass concentration of 0.11mol / L, and then Add the dehydrated alcohol of 1.55% (accounting for the percentage of reaction bottom liquid quality) wherein, stir evenly, and keep its temperature constant at 80 ℃, wherein, the water glass total amount that uses in the described precipitation reaction includes consumption in the preparation of bottom liquid amount.

[0077] (2) Reaction stage: in the reaction bottom liquid of step (1), add the concentrated sulfuric acid and water glass solution simultaneously, carry out reaction, keep stirring during; Wherein, in the whole reaction stage, reaction temperature remains constant,...

Embodiment 3

[0089] The present embodiment provides a kind of method for preparing white carbon black, and its specific method is:

[0090] (1) Preparation of reaction bottom liquid: add water to the reaction kettle, use oil bath heating to control the temperature of water at 75°C, add a certain amount of water glass solution, prepare a reaction bottom liquid with a water glass concentration of 0.20mol / L, and then Add the dehydrated alcohol of 2.8% (accounting for the percentage of reaction bottom liquid quality) wherein, stir evenly, and keep its temperature constant at 75 ℃, wherein, the water glass total amount that uses in the described precipitation reaction includes consumption in the bottom liquid preparation amount.

[0091] (2) Reaction stage: in the reaction bottom liquid of step (1), add the concentrated sulfuric acid and water glass solution simultaneously, carry out reaction, keep stirring during; Wherein, in the whole reaction stage, reaction temperature remains constant, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com