High-conductivity and low-hardness NBR (nitrile-butadiene rubber) blended rubber and preparation method thereof

A low-hardness, high-conductivity technology, applied in the field of rubber formulations, can solve the problems of high production cost, complicated preparation process, and low production efficiency, and achieve the effect of improving conductivity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

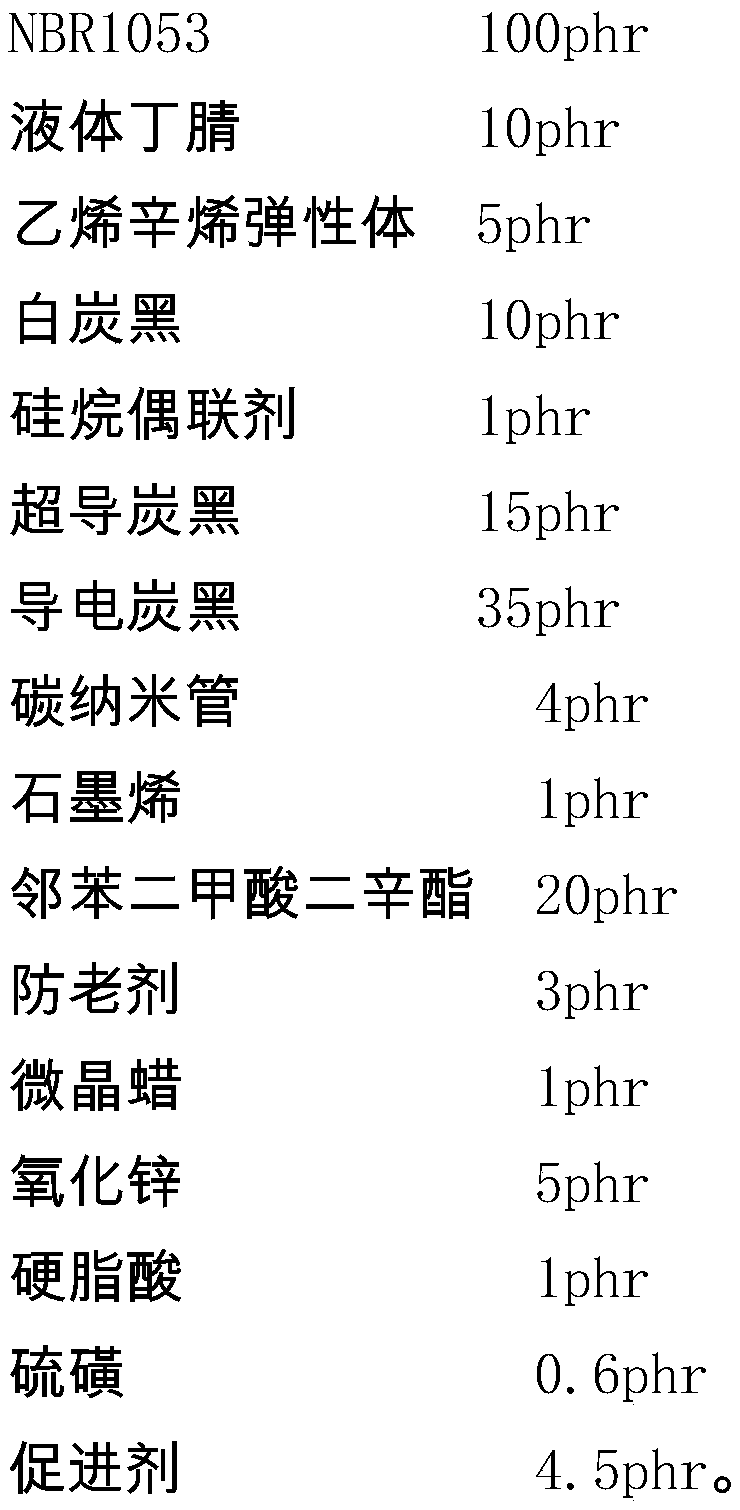

[0024] Formula (mass parts phr)

[0025]

[0026]

[0027] Steps: (1) Set the initial temperature of the internal mixer to 70°C and the rotational speed to 65rpm, then put the nitrile rubber into the internal mixer and masticate for 1.5 minutes, then put in the active agent, anti-aging agent, white carbon black, Liquid nitrile rubber, dioctyl phthalate and 1 / 2 metered portion of conductive carbon black and all carbon nanotubes and graphene, put in the remaining conductive carbon black after banburying for 1.5min, and then banbury for 1.5min, Lift the upper bolt of the internal mixer for cleaning, and then internally mix to about 140°C to remove the glue;

[0028] (2) Adjust the roller pitch of the open mill to 1.5mm, re-mill the film from the internal mixer for 2-3 times, cover the rolls, then put in sulfur and accelerator, turn the rubber three times on the left and right, and then turn the film on the open mill Adjust the roller distance to 0.2mm for thin pass 6-8 tim...

Embodiment approach 2

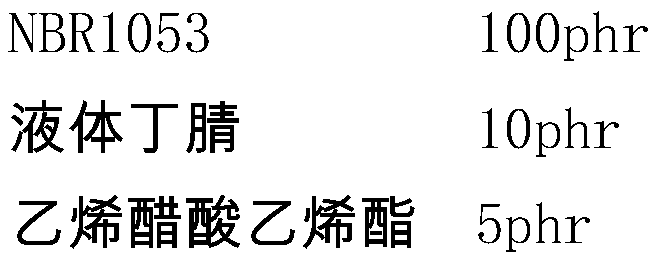

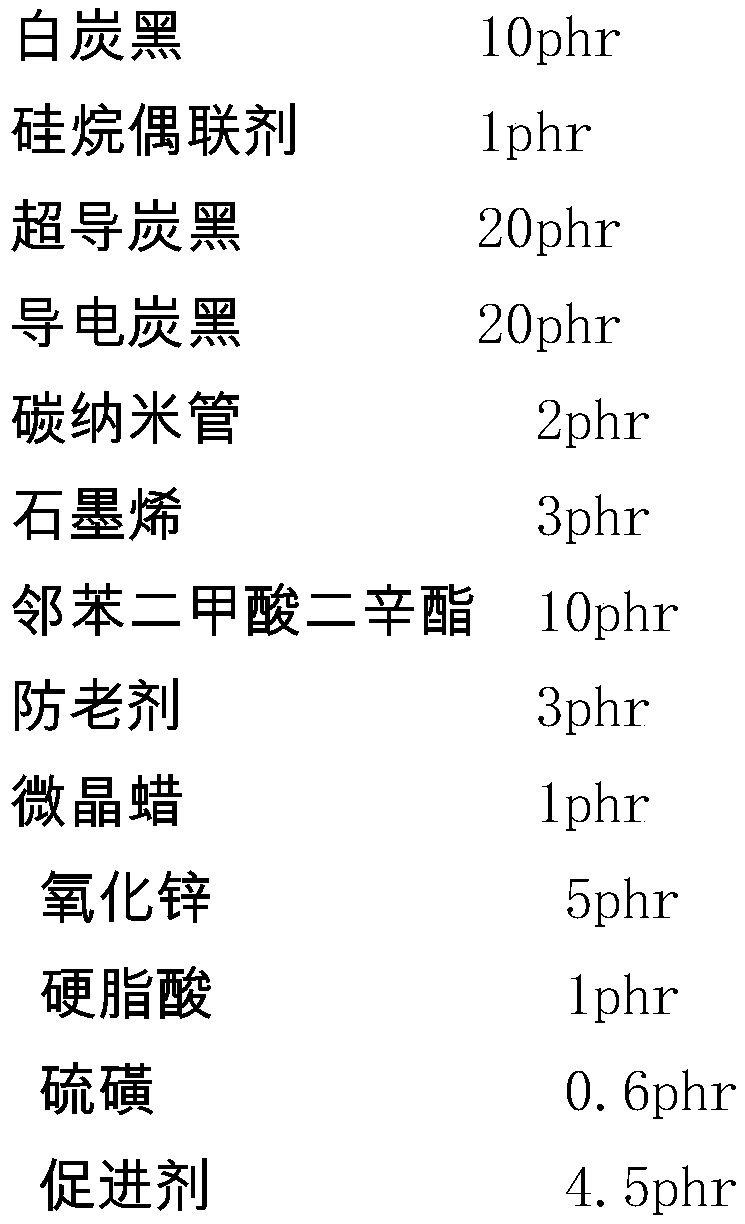

[0030] Formula (mass parts phr)

[0031]

[0032]

[0033] The main steps:

[0034](1) Set the initial temperature of the internal mixer to 70°C and the rotational speed to 65rpm, then put the nitrile rubber into the internal mixer and masticate for 1.5min, then put in the active agent, anti-aging agent, white carbon black, liquid butyl Nitrile rubber, dioctyl phthalate, and 1 / 2 metered portion of conductive carbon black and all carbon nanotubes and graphene, put in the remaining conductive carbon black after 1.5 minutes of banburying, and then banbury for 1.5 minutes, lift the compactor Clean the top bolt on the mixer, and then banbury to about 140°C to remove the glue;

[0035] (2) Adjust the roller pitch of the open mill to 1.5mm, re-mill the film from the internal mixer for 2-3 times, cover the rolls, then put in sulfur and accelerator, turn the rubber three times on the left and right, and then turn the film on the open mill Adjust the roller distance to 0.2mm for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com