Rubber composition for improving tearing property of rubber and application

A rubber composition and rubber technology, which is applied in the field of rubber composition for tire treads and tires, can solve the problems of increasing the amount of carbon black, reducing the processing performance of the composition, and affecting the life of the tire, so as to achieve Mooney viscosity reduction and tear-off Improvement of elongation and tear strength, compatibility enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

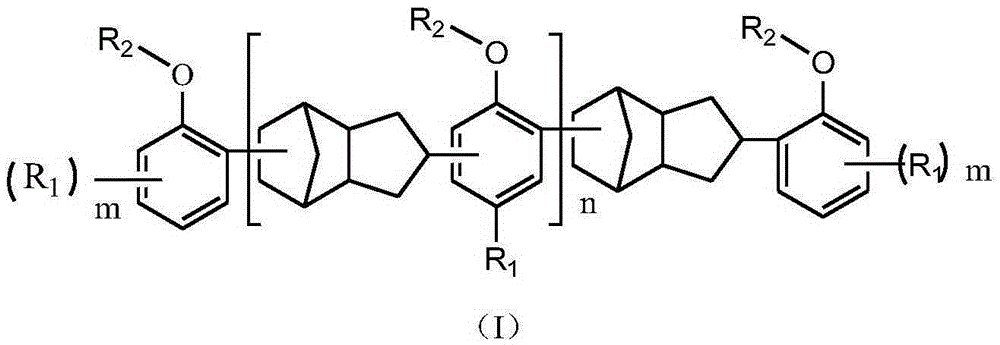

Method used

Image

Examples

Embodiment 1

[0046] Add 1mol of phenol, 60ml of toluene, BF 3 ·Et 2 O catalyst 8ml, through N 2 Protection, heat up to 70°C to completely dissolve phenol, slowly add 0.8mol of DCPD dropwise, control the reaction temperature at 110-120°C, after 2 hours of reaction, add 2mL of ethanol to quench the catalyst, change to a distillation state to evaporate the toluene solvent and then return to reflux state. Add 0.5 g of p-toluenesulfonic acid, add 0.7 mol of styrene drop by drop, continue to add 150 g of wood rosin after reacting for 2 hours, and react for 1 hour at 130°C, change the condenser from the reflux state to the distillation state, heat the reactant to 190°C, slowly Turn on the vacuum to the maximum vacuum degree and keep it for 15 minutes, after neutralizing with sodium hydroxide, discharge the material. A wood rosin-modified phenol-DCPD resin was obtained. The softening point of the resin was determined to be 125.6°C.

Embodiment 2

[0048] Add 300 g of commercially available phenol-DCPD resin and 2.5 g of hydrochloric acid to a 1000 ml round bottom flask equipped with a stirring device, a thermometer, and a reflux condenser, and heat up to 150 ° C. After the resin is completely dissolved, add 1 mol of а-pinene dropwise, After reacting for 2 hours, continue to add 200 g of tall oil rosin and gum rosin mixture. After reacting for 1 hour at 150 ° C, change the condenser from the reflux state to the distillation state, heat the reactant to 190 ° C, slowly turn on the vacuum to the maximum vacuum degree and keep it for 15 min, use After being neutralized by sodium hydroxide, the material is discharged. A rosin-modified phenol-DCPD resin was obtained. The softening point of the resin was determined to be 115.3°C.

Embodiment 3

[0050] Add 1mol of phenol, 50ml of toluene, BF 3 ·Et 2 O catalyst 8ml, through N 2 Protection, heat up to 70°C to completely dissolve phenol, slowly add 0.8mol of DCPD dropwise, control the reaction temperature at 110-120°C, after 2 hours of reaction, add 2mL of ethanol to quench the catalyst, change to a distillation state to evaporate the toluene solvent and then return to reflux state. Add 0.5 g of p-toluenesulfonic acid, add 0.6 mol of α-methylstyrene dropwise, continue to add 100 g of gum rosin after 2 hours of reaction, and after 1 hour of reaction at 130 ° C, change the condenser from the reflux state to the distillation state, and heat the reactants to At 190°C, slowly turn on the vacuum to the maximum vacuum degree and keep it for 15 minutes, neutralize with sodium hydroxide, and discharge. A wood rosin-modified phenol-DCPD resin was obtained. The softening point of the resin was determined to be 123.7°C.

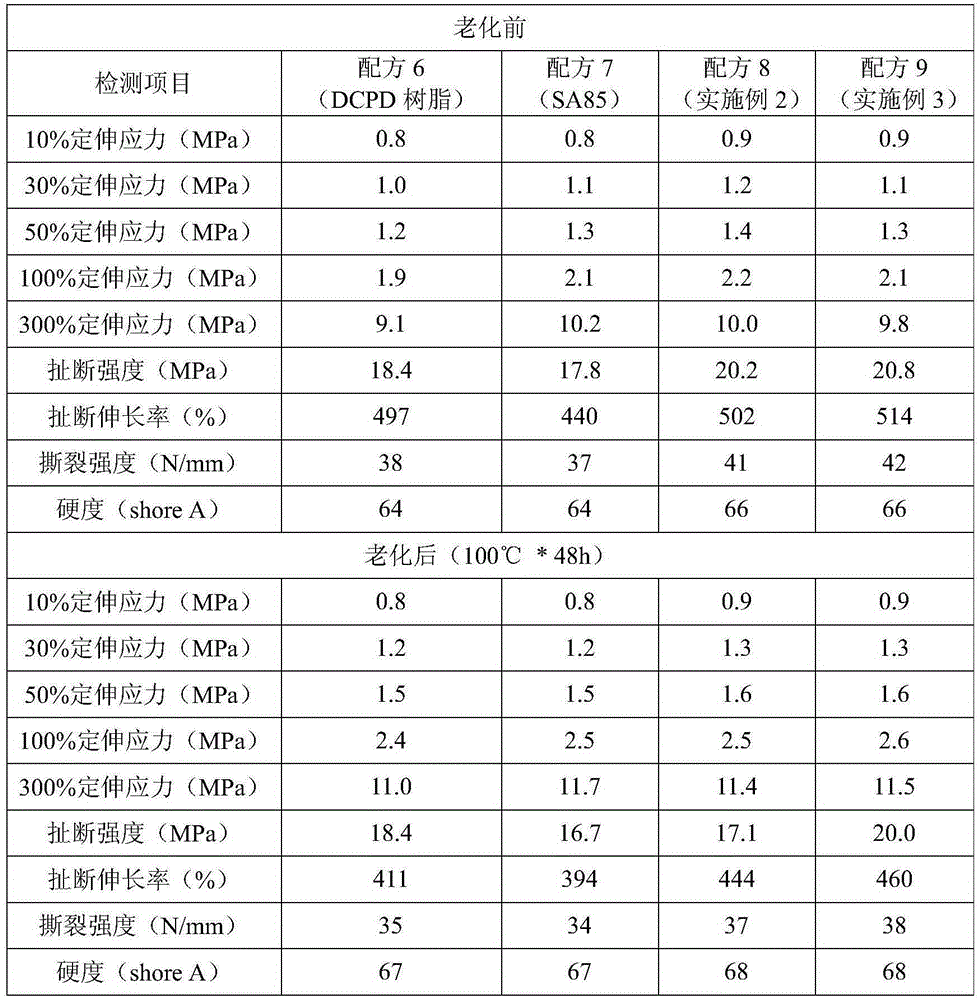

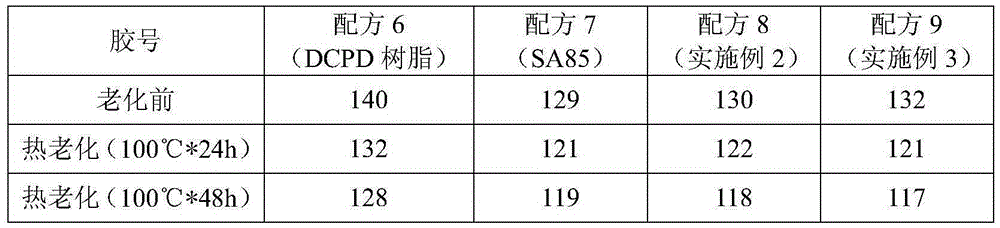

[0051] 2. Preparation and performance test of rubber com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com