Polybutadiene grafted isoprene rubber and preparation method thereof, vulcanizate and rubber compound

A technology of polybutadiene and isoprene rubber, which is applied in the field of polybutadiene grafted isoprene rubber and its preparation, vulcanized rubber and mixed rubber, which can solve the problems of unfavorable heat transfer, unfavorable cold flow of raw rubber, and rubber Problems such as high liquid viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

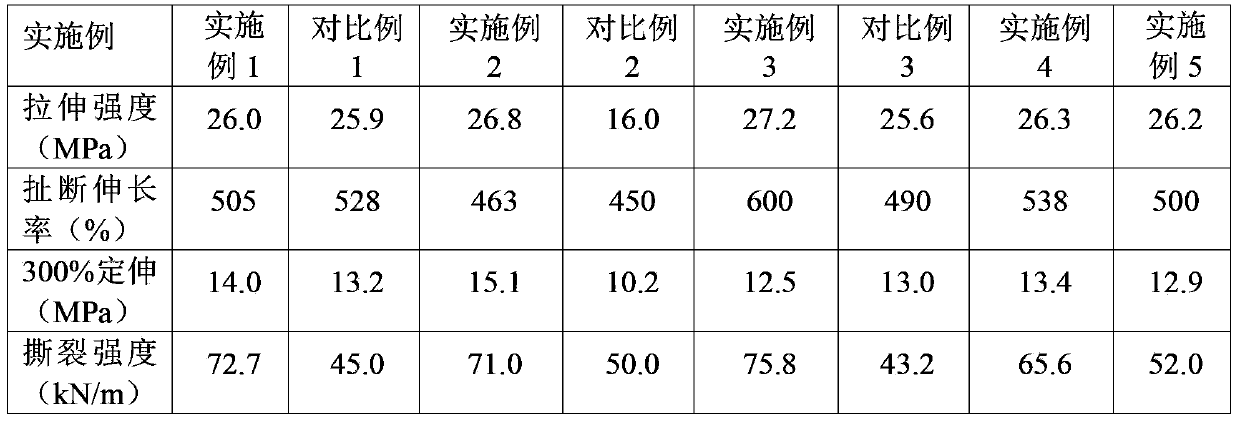

Examples

preparation example Construction

[0024] The preparation method of polybutadiene grafted isoprene rubber provided by the invention comprises the following steps:

[0025] (1) In the presence of the first catalyst, butadiene is polymerized in the first organic solvent, the conditions of the polymerization reaction are such that the number average molecular weight is 2000-10000, preferably 3000-7500, and the molecular weight distribution is 2-3 polybutadiene, and 80-95 mole % of said polybutadiene contains conjugated double bonds;

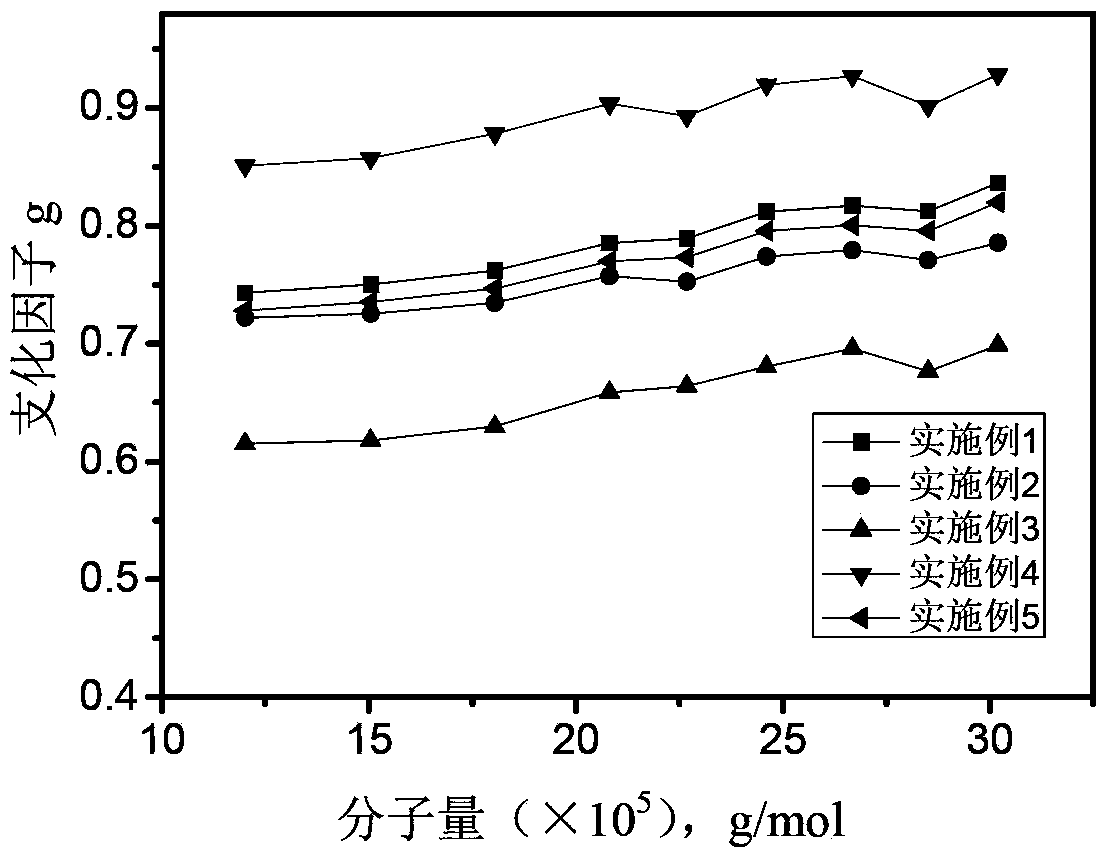

[0026] (2) In the presence of a second catalyst, the polybutadiene obtained in step (1) is contacted with isoprene in a second organic solvent, and the contact conditions are such that the polybutadiene and isoprene The diene is copolymerized to obtain a number average molecular weight of 2×10 5 -5×10 5 , preferably 3×10 5 -4×10 5 , a polybutadiene grafted isoprene rubber with a molecular weight distribution of 3-4; based on the total weight of the polybutadiene and isoprene, the...

preparation example 1

[0062] This preparation example is used to illustrate the nickel-based catalyst provided by the present invention and its preparation method.

[0063] Under nitrogen protection at 10 °C, 0.3 mol nickel naphthenate (purchased from Shanghai Minghuan Chemical Co., Ltd., the same below), 3 mol sesquiethyl aluminum chloride, 0.45 mol N-methylpyrrolidone (NMP) and 2L of hexane was mixed evenly in a dry aging tank and aged for half an hour to obtain a nickel-based catalyst with a concentration of 0.15 mol / L (calculated as nickel element).

preparation example 2

[0065] This preparation example is used to illustrate the neodymium-based catalyst provided by the present invention and its preparation method.

[0066] Under nitrogen protection, mix 180ml of 0.05mol / L hexane solution of neodymium neodecanoate, 45ml (0.45mol) isoprene and 1kg of hexane, and adjust the temperature to 10°C, add 34ml of A hexane solution of 0.8mol / L diethylaluminum chloride was aged for 15 minutes; after adding 50ml of a hexane solution of triisobutylaluminum with a concentration of 2mol / L, the aging was continued for 24h to obtain a concentration of 0.005mol / L (calculated as neodymium element) neodymium-based catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com