Full-terrain tire tread rubber reinforced and filled with diatomite and preparation method of tread rubber

A technology of tire tread and diatomite, which is applied in the direction of special tires, tire parts, transportation and packaging, etc., can solve the problems of unfavorable production and environmental protection, long rubber mixing time, high price of white carbon black, etc., and achieve the vulcanization time Short, low price, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A diatomite reinforced all-terrain tire tread rubber, comprising the following raw materials in parts by mass: 25 parts of 20# standard rubber, 150265 parts of styrene-butadiene rubber, 900010 parts of butadiene rubber, 20 parts of diatomaceous earth, 50 parts of precipitated white carbon black, 2 parts of ordinary sulfur, 4 parts of zinc oxide, 3 parts of stearic acid, 0.5 parts of accelerator CZ, 0.25 parts of accelerator TMTD, 0.5 parts of accelerator NOBS, 1 part of antioxidant MB, 1 part of anti-aging agent SPC, 10 parts of engine oil, 1.4 parts of coupling agent KH570, 2 parts of glycerol;

[0027] The preparation method of the above-mentioned all-terrain tire tread rubber specifically includes the following steps: use an open mill to plasticize the 20# standard rubber, then add styrene-butadiene rubber 1502 and butadiene rubber 9000, mix evenly, adjust the roller distance and the rubber stop To control the proper accumulation of glue, add zinc oxide, stearic acid...

Embodiment 2

[0035] A diatomite-reinforced and filled all-terrain tire tread rubber, comprising the following raw materials in parts by mass:

[0036] 20# standard rubber, 25 parts; styrene-butadiene rubber 1502, 65 parts; butadiene rubber 9000, 10 parts; diatomaceous earth, 30 parts; precipitated white carbon black, 50 parts; stearic acid, 3 parts; accelerator CZ, 0.5 parts; accelerator TMTD, 0.25 parts; accelerator NOBS, 0.5 parts; antioxidant MB, 1 part; antioxidant SPC, 1 part; engine oil, 10 parts; Joint agent KH570, 1.6 parts; glycerol, 2 parts.

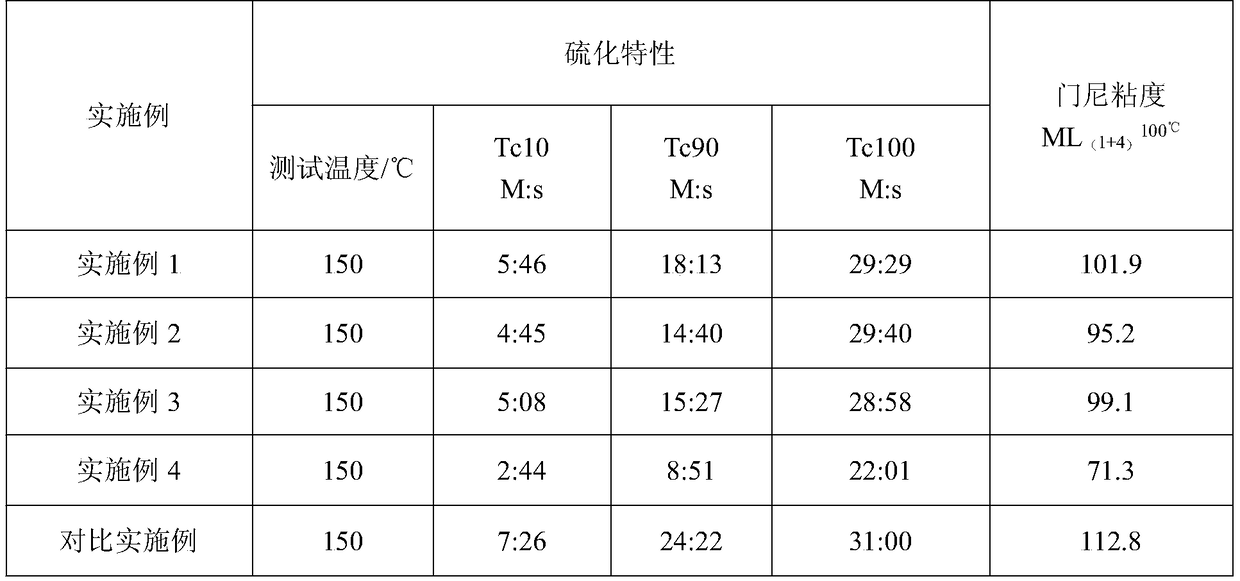

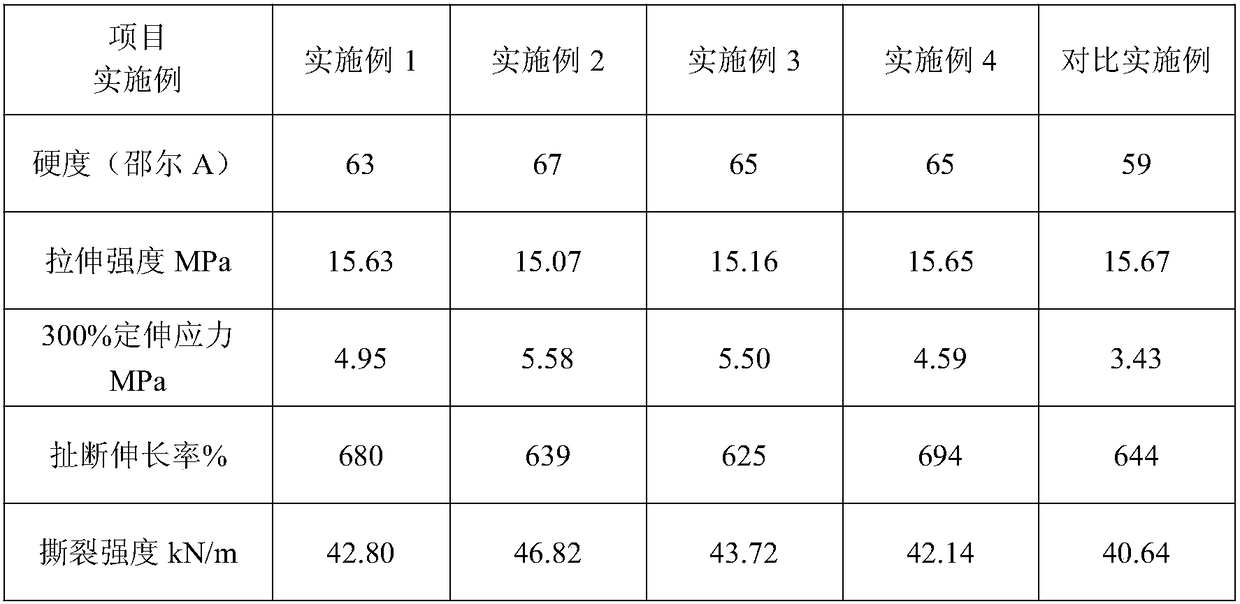

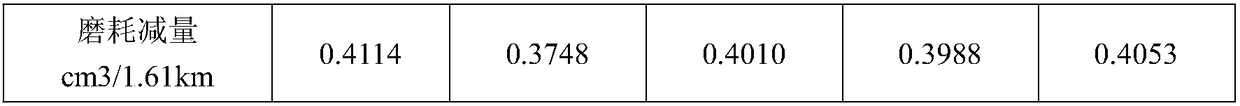

[0037] Its preparation method and performance testing method are the same as in Example 1, its vulcanization characteristics and Mooney viscosity are shown in Table 2, and its physical and mechanical properties are shown in Table 3.

Embodiment 3

[0039] A diatomite-reinforced and filled all-terrain tire tread rubber, comprising the following raw materials in parts by mass:

[0040] 20# standard rubber, 25 parts; styrene-butadiene rubber 1502, 65 parts; butadiene rubber 9000, 10 parts; diatomaceous earth, 40 parts; precipitated white carbon black, 50 parts; stearic acid, 3 parts; accelerator CZ, 0.5 parts; accelerator TMTD, 0.25 parts; accelerator NOBS, 0.5 parts; antioxidant MB, 1 part; antioxidant SPC, 1 part; engine oil, 10 parts; Joint agent KH570, 1.8 parts; glycerol, 2 parts.

[0041] Its preparation method and performance testing method are the same as in Example 1, its vulcanization characteristics and Mooney viscosity are shown in Table 2, and its physical and mechanical properties are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com