Digital automatic control method for tire vulcanization process

A technology of tire vulcanization and vulcanization degree, applied in tires, household appliances, other household appliances, etc., can solve the problems of long time, waste of resources, tire damage, etc., to achieve short tire curing time, save energy consumption, reduce tire wear and tear. effect of sulfur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

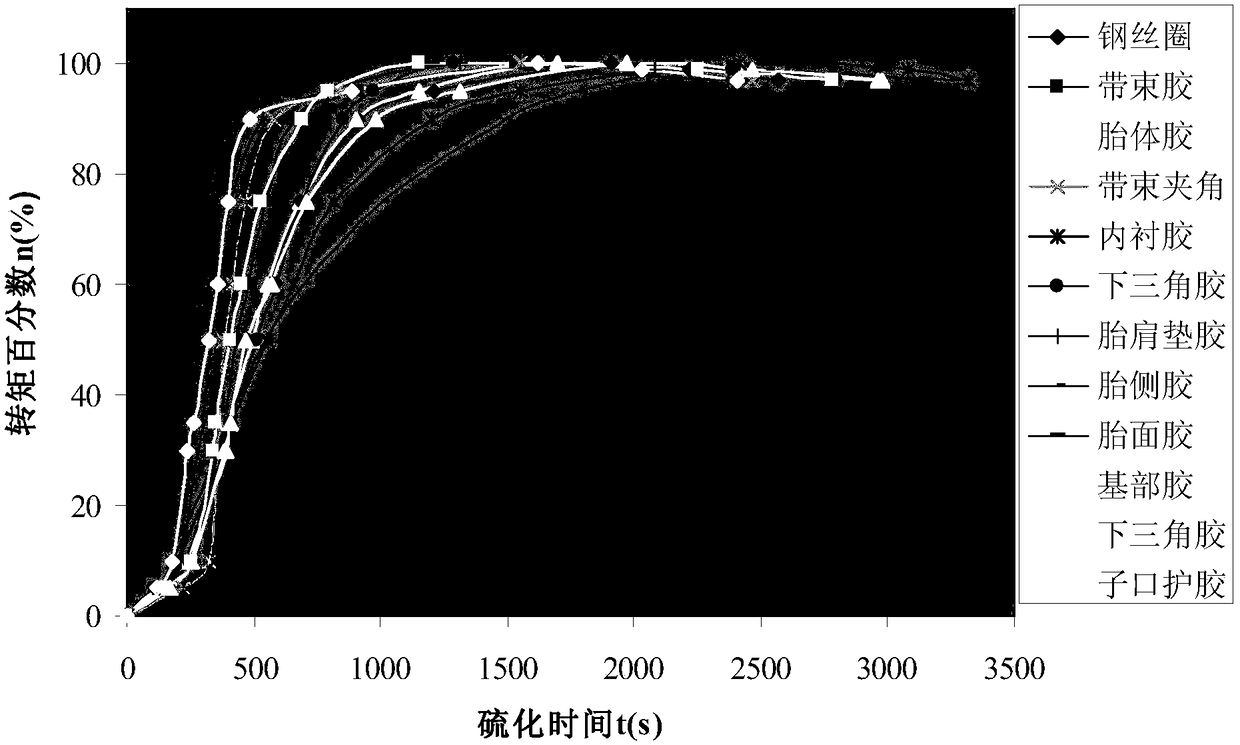

[0020] In the second step, input the tire structure design drawing, mold design drawing, thermodynamic parameters and vulcanization characteristic parameters of each material, establish the heat conduction differential equation of the vulcanization process, and calculate the temperature values of each part of the tire in real time by solving the equation, and then according to The vulcanization kinetic model calculates the degree of vulcanization. The specific implementation method is as follows:

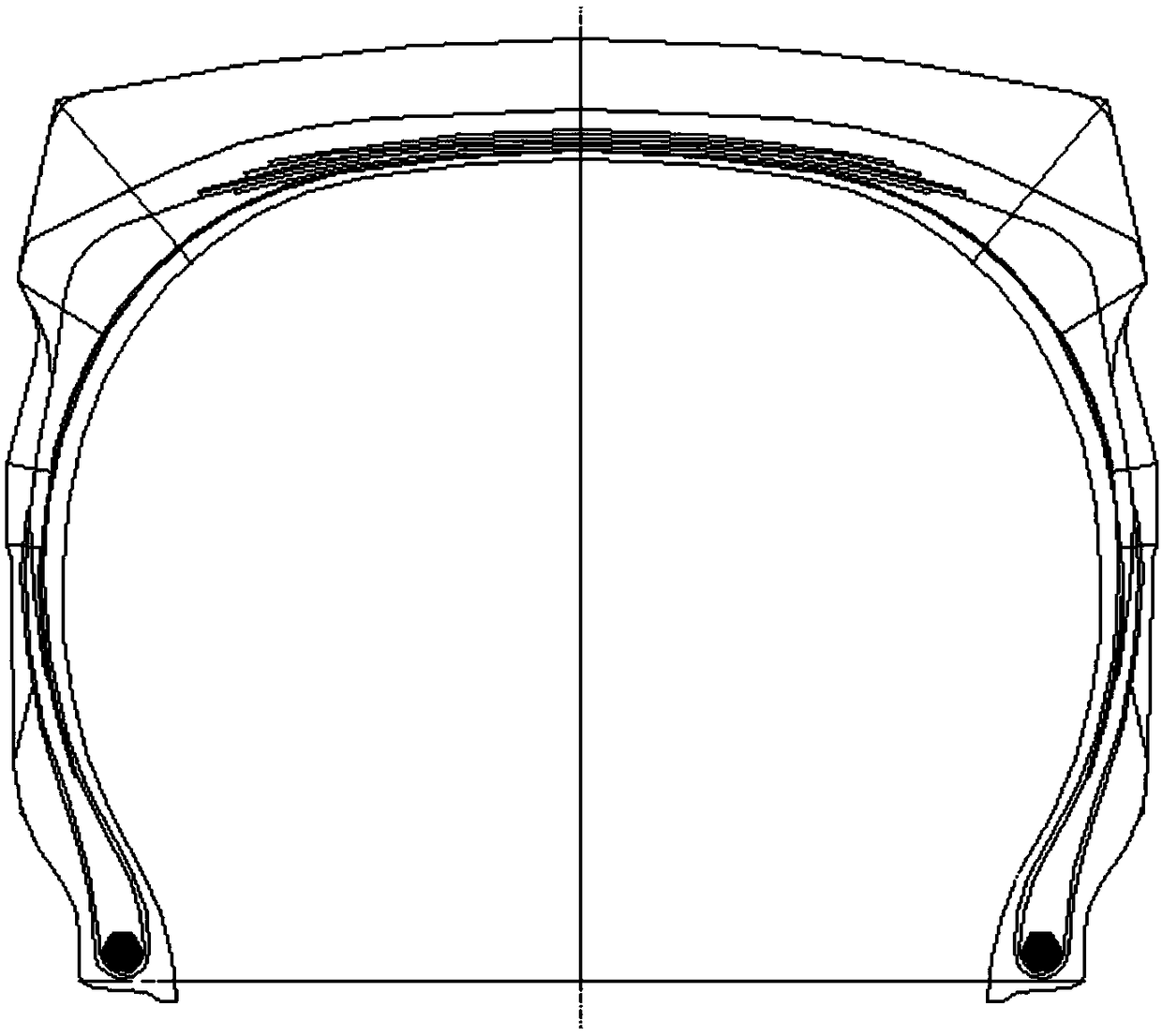

[0021] (1) According to the structural design drawing and mold design drawing of the tire (such as figure 1 and figure 2 shown) to determine the spatial position of each runner and each part of the tire, and then provide initial conditions for solving the temperature change of each part inside the tire. According to Fourier's basic law of heat conduction and the first law of thermodynamics, the three-dimensional transient heat conduction differential equation in cylindrical coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com