Low-temperature-resistant mixed silicone rubber and preparation method thereof

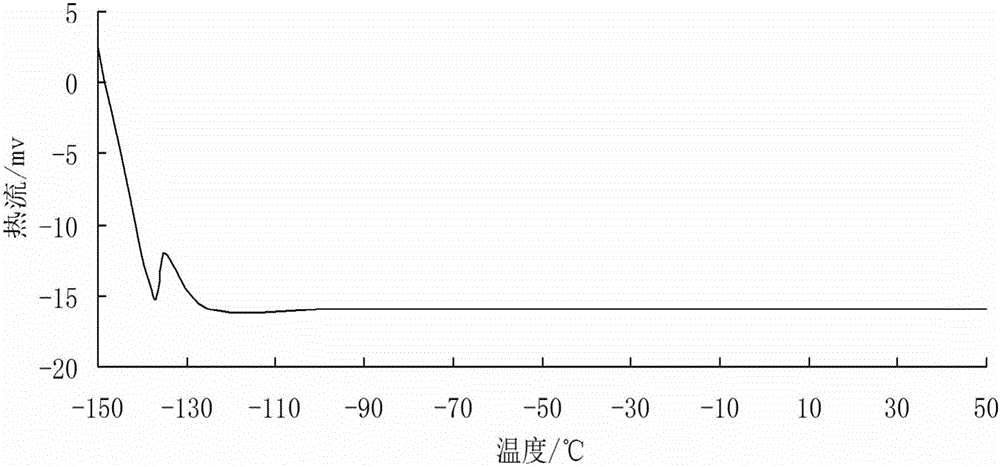

A technology of mixing silicone rubber and low temperature resistance, which is applied in the field of rubber production, and can solve the problems of long heat vulcanization time and low temperature resistance of low temperature resistant silicone rubber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Technical scheme of the present invention is as follows:

[0009] A kind of low-temperature-resistant mixing silicone rubber, the raw material components by weight are as follows: (A) 100 parts of low-temperature resistant silicone rubber raw rubber, (B) 7-10 parts of high-vinyl low-temperature resistant silicone rubber raw rubber, (C) white carbon 50-60 parts of black (D) 3-5 parts of hydroxyl silicone oil, (E) 0.3-1 part of dimethyldimethoxysilane, (F) 5-10 parts of hydrogen-containing silicone oil, (G) 0.01-0.05 parts of platinum catalyst share.

[0010] According to the present invention, preferably, the low-temperature-resistant silicone rubber raw rubber is vinyl silicone rubber raw rubber with a molecular weight of 600,000-750,000 and a vinyl mole percentage of 0.05-0.16%.

[0011] According to the present invention, preferably, the molecular weight of the high-vinyl low-temperature-resistant raw silicone rubber is 550,000-650,000, and the molar percentage of vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com