Rapidly vulcanized fluoroelastomer and preparation method thereof

A rapid vulcanization and elastomer technology, applied in the chemical field, can solve the problems of low polymerization efficiency and slow polymerization speed, and achieve the effects of high fuel penetration resistance, fast vulcanization speed, and short vulcanization time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

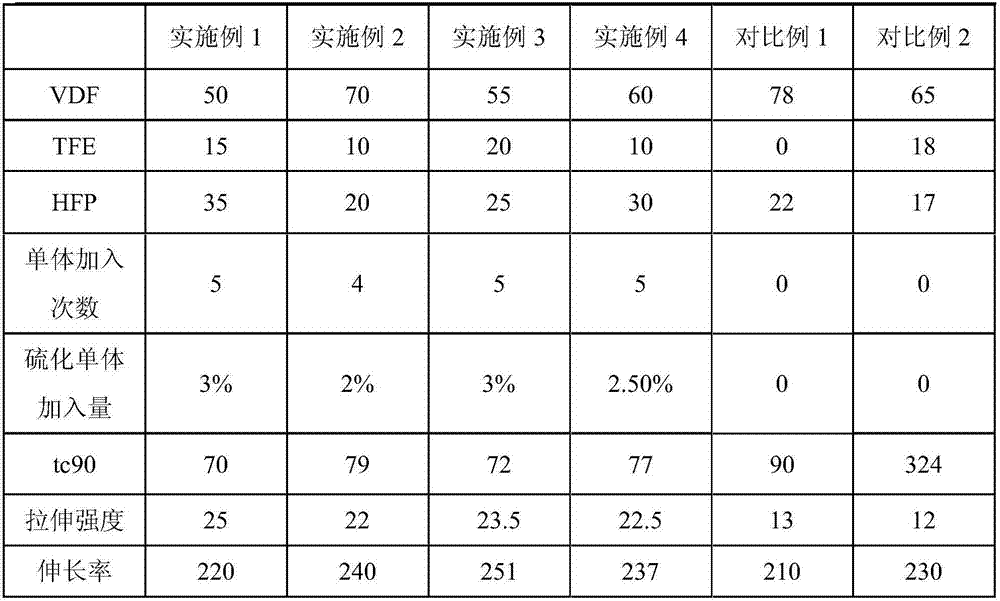

Embodiment 1

[0040] Take a 10L polymerization kettle as an example to prepare fluoroelastomer.

[0041] The mole fraction is 7.8 kg of comonomers of 50% vinylidene fluoride, 15% tetrafluoroethylene and 35% hexafluoropropylene monomers, which are prepared into comonomers in the storage tank for future use.

[0042] Add 6.5kg of ion-free water, 65ml of 10wt% sodium perfluorooctanoate solution, and 10g of borax into the cleaned polymerization kettle; evacuate and remove oxygen until the oxygen content is less than 30ppm. Add comonomer to make the polymerization kettle pressurized to a reaction pressure of 1.9 MPa. When the temperature of the polymerization kettle rises to a reaction temperature of 110° C., a metering pump is used to inject 6.5 g of ammonium persulfate initiator with a mass fraction of 10 wt % for reaction. At 70% reaction, 6.5 g of chain terminator 1,2-diiodotetrafluoroethane was added. Half an hour after the reaction started, 450 g of organic initiator tert-butyl hydroperox...

Embodiment 2

[0047] Take a 10L polymerization kettle as an example to prepare fluoroelastomer.

[0048]The preparation method of this example is the same as that of Example 1, except that the mole fractions are 70% vinylidene fluoride, 10% tetrafluoroethylene and 20% hexafluoropropylene monomer, and the comonomer is prepared as 4.55 kg. When the reaction pressure is 1 MPa and the reaction temperature is 130° C., the inorganic initiator is reacted with 20 g of ammonium persulfate initiator with a mass fraction of 10 wt %. When the reaction is 80%, 3.25 g of chain terminator methylene bromide is added. The vulcanization point monomer trifluoroiodoethylene was added in batches after the ammonium persulfate initiator was added to initiate the polymerization reaction, once every 30 minutes on average, 4 times in total, and the total amount added was 2% of the reaction mixed monomer. Half an hour after the reaction started, 650 g of organic initiator tert-butylperoxymaleic acid with a mass fract...

Embodiment 3

[0051] Take a 10L polymerization kettle as an example to prepare fluoroelastomer.

[0052] The preparation method of this example is the same as that of Example 1, except that 55% of vinylidene fluoride, 20% of tetrafluoroethylene and 25% of hexafluoropropylene monomers are used to prepare 6 kg of comonomers. The reaction pressure is 3.0 MPa, the reaction temperature is 85° C., and the inorganic initiator is 32.5 g of ammonium persulfate initiator whose mass fraction is 10 wt %. At 70% reaction, 4.3 g of chain terminator methyl bromide was added. The vulcanization point monomer 1-bromo-2,2-difluoroethylene is added in batches after the ammonium persulfate initiator is added to initiate the polymerization reaction. During the reaction process, the vulcanization point monomer 1-bromo-2,2- Ethylene difluoride was added 5 times in total, and the total amount added was 3% of the reaction mixed monomers. Half an hour after the reaction started, 325 g of diisopropyl peroxydicarbona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com