Improved oil seal type mold

An improved, oil-sealing technology, used in household appliances, other household appliances, household components, etc., can solve the problems of unstable product quality, increased tearing difficulty, edge damage, etc., and achieves short curing time and high material utilization. , the effect of short production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

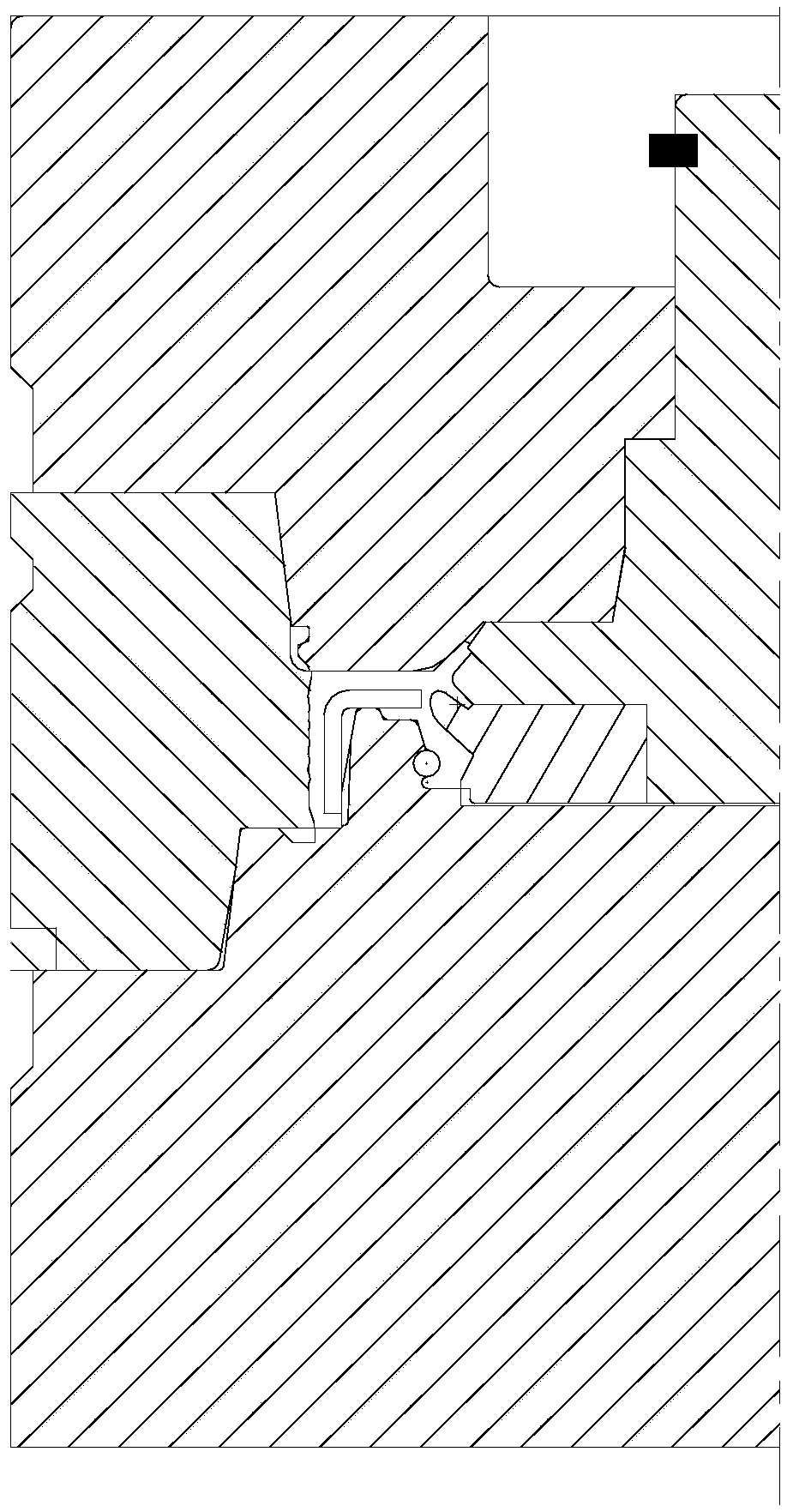

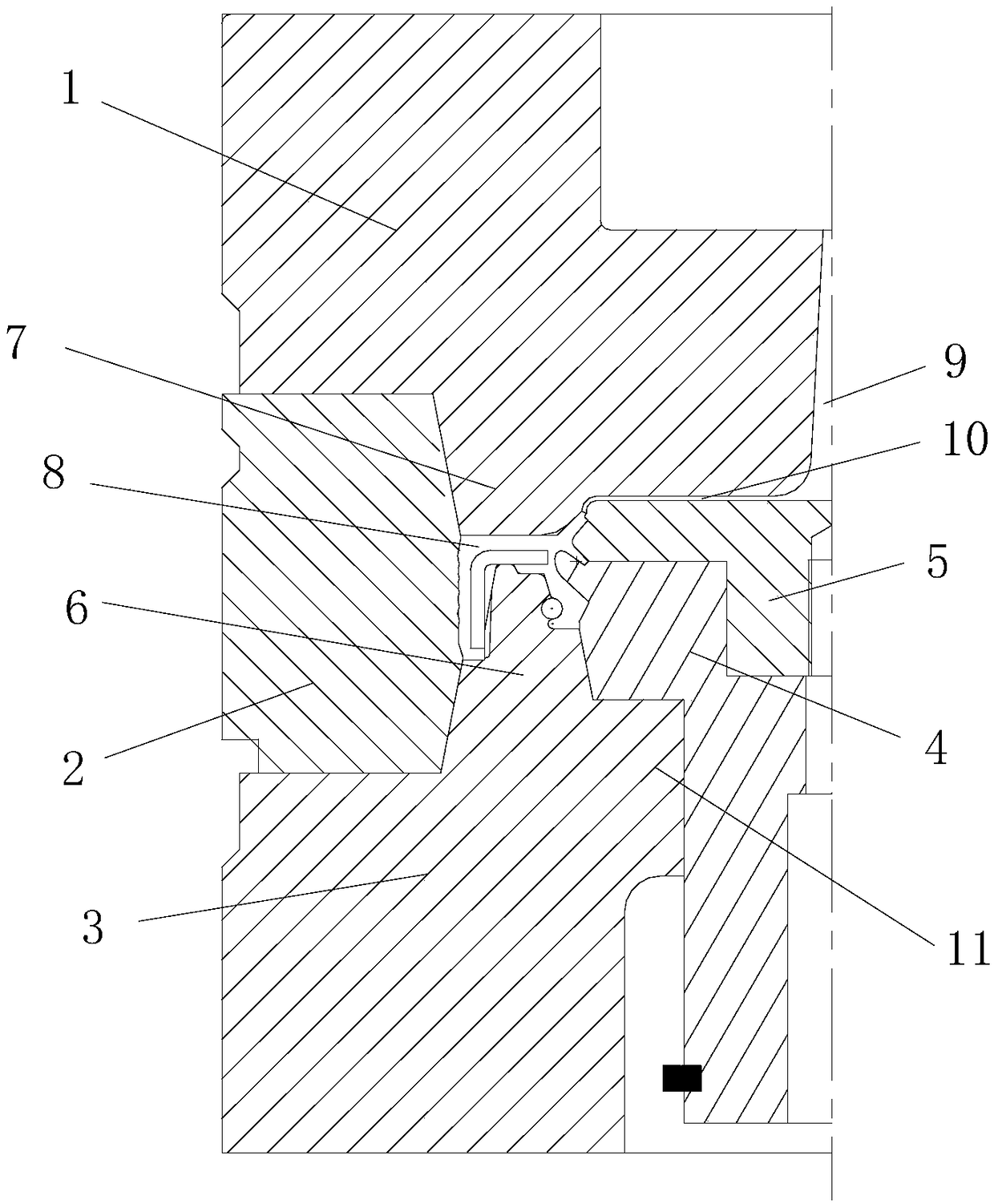

[0017] refer to figure 2 , the present invention proposes an improved oil seal type mold, including an upper mold 1 , a middle mold 2 , a lower mold 3 , a first mold core 4 and a second mold core 5 . The upper mold 1, the middle mold 2, and the lower mold 3 are arranged up and down. The middle mold 2 has a first mold cavity, and the top of the lower mold 3 is provided with an annular support platform 6 extending into the first mold cavity for supporting the oil seal skeleton. The mold core 4 is arranged in the first mold cavity and the bottom end of the first mold core 4 abuts against the lower mold 3 , the second mold core 5 is arranged in the first mold cavity and the second mold core 5 abuts against the first mold core 4 Rely, the bottom of the upper mold 1 is provided with an annular platform 7 extending into the first mold cavity. In the mold closing state, the upper mold 1, the middle mold 2, the lower mold 3, the first core 4, and the second core 5 A cavity 8 is forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com