Fluororubber and synthesis method thereof

A synthesis method and technology of fluororubber, applied in the field of materials, can solve the problems of easy wall formation of reactors, lower polymerization temperature, and high production costs, and achieve the effects of short vulcanization time, fast vulcanization speed, and low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

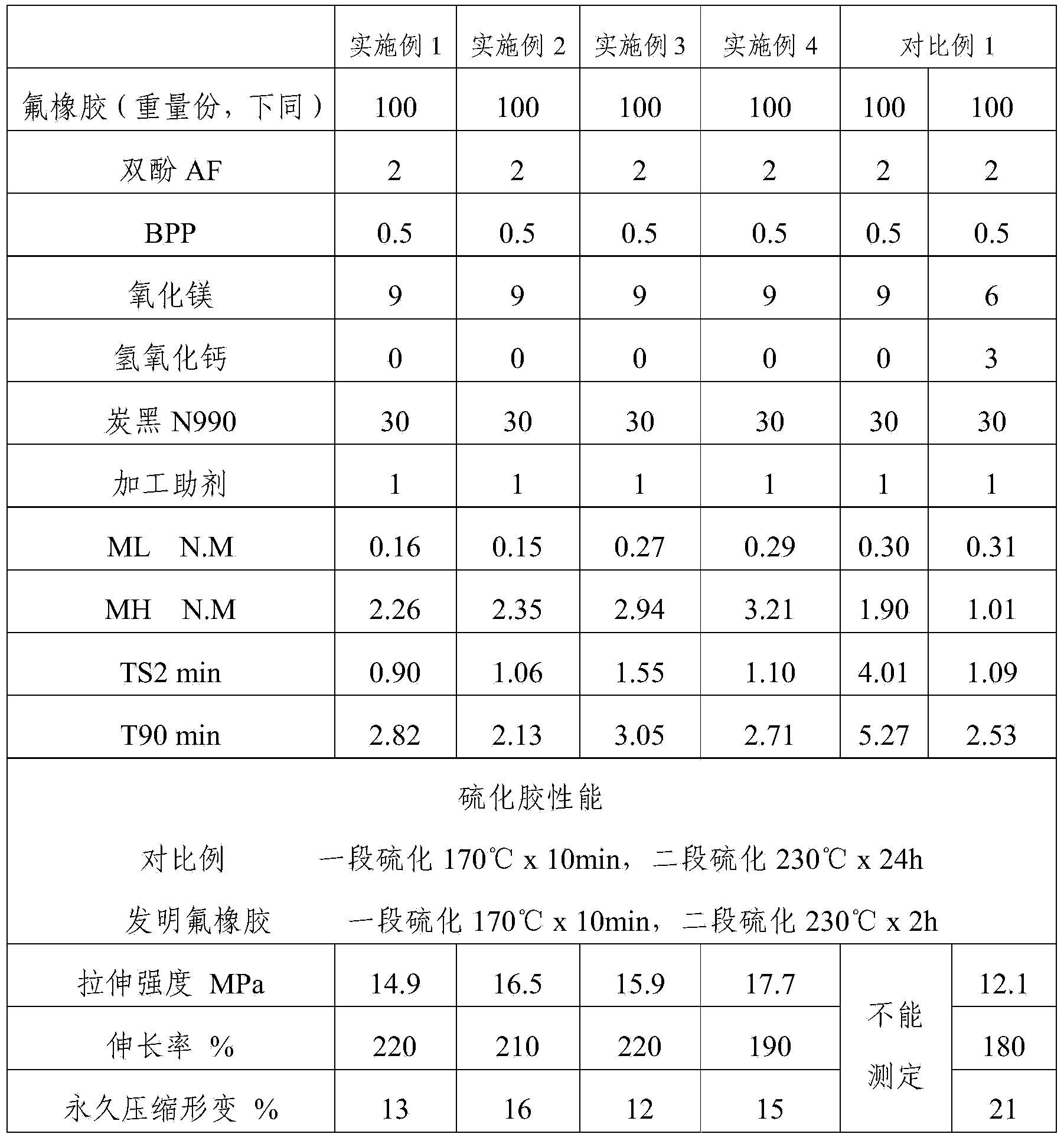

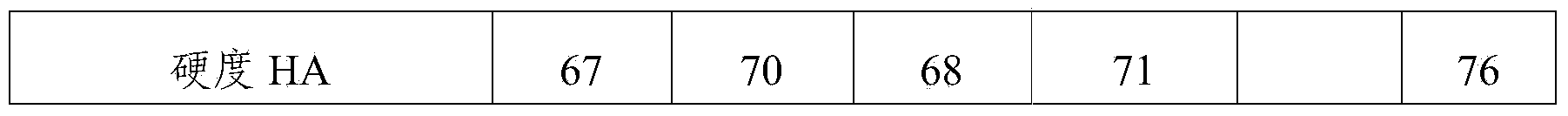

Examples

Embodiment 1

[0054] The batch radical emulsion polymerization of the present invention is carried out in a 50L high-pressure reactor to prepare fluororubber. Add 30L deionized water and 500ml 5wt% perfluorooctanoic acid ammonium aqueous solution in the reactor, 40g pH regulator ammonium carbonate, the air in the vapor space in the reactor is first replaced with nitrogen, and then the initial mixed monomer (vinylidene fluoride: hexafluoropropylene =35:65(mol)) to make the oxygen content less than 20ppm. The stirring was started, and the temperature inside the reactor was raised to 60°C. Add chain transfer agent methane gas (15g), and use a diaphragm compressor to add the above-mentioned initial mixture monomer into the reactor to raise the pressure to 3.5Mpa.

[0055] When the pressure of the reactor reached 3.5 MPa, the mixed monomers in the reactor were fully mixed, and then 10 g of initiator azobisisobutylamidine hydrochloride was added to start the reaction. During the reaction proces...

Embodiment 2

[0059] The batch radical emulsion polymerization of the present invention is carried out in a 50L high-pressure reactor to prepare fluororubber. Add 30L deionized water and 500ml 5wt% perfluorooctanoic acid ammonium aqueous solution in the reactor, 40g pH regulator ammonium carbonate, the air in the vapor space in the reactor is first replaced with nitrogen, and then the initial mixed monomer (vinylidene fluoride: hexafluoropropylene : Tetrafluoroethylene=33:55:12 (mol)) replacement, so that the oxygen content is less than 20ppm. The stirring was started, and the temperature inside the reactor was raised to 60°C. Add chain transfer agent methane gas (15g), and use a diaphragm compressor to add the above-mentioned initial mixture monomer into the reactor to raise the pressure to 3.5Mpa.

[0060] When the pressure of the reactor reached 3.5 MPa, the mixed monomers in the reactor were fully mixed, and then 8 g of initiator azobisisobutylamidine hydrochloride was added to start t...

Embodiment 3

[0064] The batch radical emulsion polymerization of the present invention is carried out in a 50L high-pressure reactor to prepare fluororubber. Add 30L deionized water and 500ml 5wt% perfluorooctanoic acid ammonium aqueous solution in the reactor, 35g pH regulator ammonium bicarbonate, the air in the vapor space in the reactor is first replaced with nitrogen, and then the initial mixed monomer (vinylidene fluoride: hexafluoro Propylene=22:78(mol)) replacement, so that the oxygen content is less than 20ppm. The stirring was started, and the temperature inside the reactor was raised to 65°C. Add chain transfer agent methane gas (15g), and use a diaphragm compressor to add the above-mentioned initial mixture monomer into the reactor to raise the pressure to 3.5Mpa.

[0065] When the pressure of the reactor reached 3.5 MPa, the mixed monomers in the reactor were fully mixed, and then 10 g of initiator azobisisobutylamidine hydrochloride was added to start the reaction. During t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com