Method for preparing zinc diphenyl dithiocarbamate

A technology of zinc diphenyldithiocarbamate and sodium diphenyldithiocarbamate, which is applied in the field of chemical synthesis, can solve the problems that cannot be prepared with zinc diphenyldithiocarbamate, and achieve superior vulcanization performance , short production cycle and short vulcanization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 10.1g of sodium hydroxide and 300g of water into the reactor and stir to dissolve, then add 49.7g of diphenylamine, stir well; start to add 83g of 40% carbon disulfide solution dropwise, and control the temperature at 40°C, stir for 1h after the dropwise addition, the reaction product The pH=9 of sodium diphenyldithiocarbamate; filter, put the filtered sodium diphenyldithiocarbamate into a replacement reactor, and add 17.5g of zinc chloride with a weight concentration of 98% under stirring to prepare Form a zinc chloride solution with a concentration of 10% by weight, stir for another 3 hours, centrifugally filter, and wash to obtain zinc diphenyldithiocarbamate with a yield of 96% and a purity of ≥98%.

Embodiment 2

[0022] Add 25g of sodium hydroxide and 300g of water into the reactor and stir to dissolve, then add 61g of diphenylamine, and stir evenly; start to add 27.2g of 80% carbon disulfide solution dropwise, and control the temperature at 30°C, stir for 3h after the addition, and the reaction product two The pH=8.8 of sodium phenyldithiocarbamate; filter, put the filtered sodium diphenyldithiocarbamate into a replacement reactor, add 21.5g of zinc chloride with a weight concentration of 98% under stirring to prepare The zinc chloride solution with a weight concentration of 10% was stirred for another 2 hours, centrifugally filtered, and washed to obtain zinc diphenyldithiocarbamate with a yield of 97% and a purity of ≥98%.

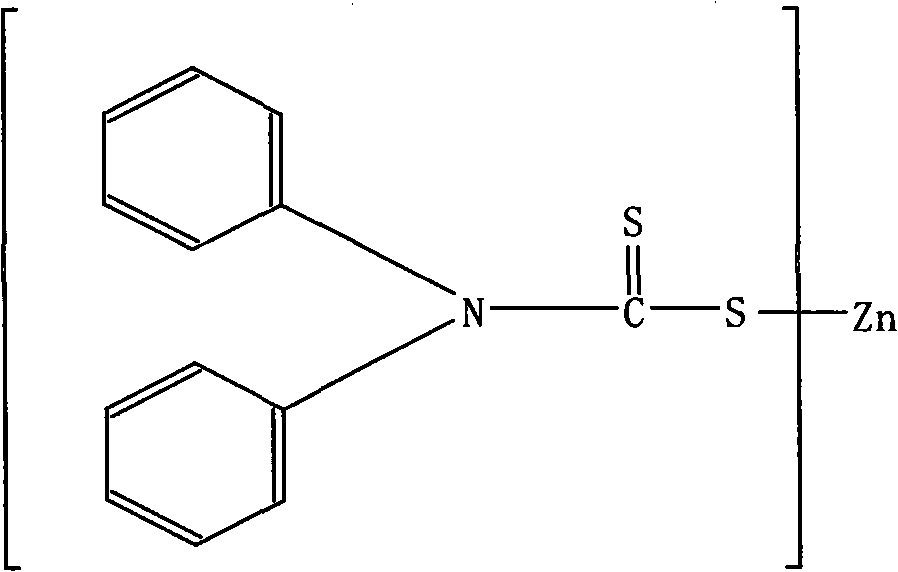

[0023] The present invention's gained rubber vulcanization accelerator zinc diphenyl dithiocarbamate has following structure:

[0024]

[0025] The product can be crushed to less than 60 mesh, sieved, and packaged to obtain the finished product.

[0026] Fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com