Cement stabilized recycled gravel method and its products

A technology of cement stabilization and gravel, applied in the field of manufactured products, can solve the problems of unfavorable cost saving, inconvenient transportation, lack of gravel, etc., and achieve the effects of widely popularizing and applying, solving the shortage of gravel resources, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

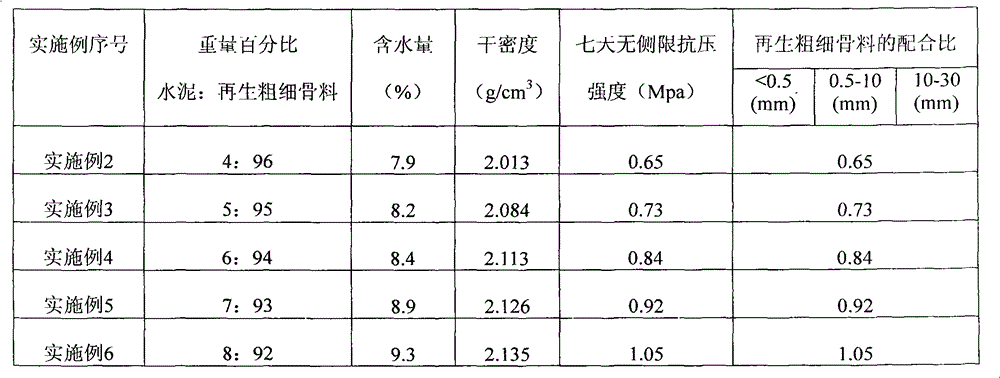

[0034] Embodiment 1: see figure 1 , a cement-stabilized regenerated gravel method provided in this embodiment, is characterized in that it comprises the following steps:

[0035] (1) Preparing raw materials: composed of the following components in weight percent:

[0036] 4-8% cement,

[0037] Regenerated coarse and fine aggregate 92-96%;

[0038] (2) Adding materials according to the proportion: weighing the cement and the regenerated coarse and fine aggregate of the corresponding proportion, and then adding the cement and the regenerated coarse and fine aggregate to the mixing equipment to prepare the mixture; the cement is Portland cement;

[0039] (3) Stirring and adding water: start the mixing equipment to stir the mixture, then add water to make the water content of the mixture 7.9-9.3%, until the mixing is uniform, and the cement-stabilized recycled gravel product is obtained.

[0040] The regenerated coarse and fine aggregate is one or more of waste concrete, compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com