Process and equipment for producing graphite dust

A graphite powder and equipment technology, applied in sustainable manufacturing/processing, electrical components, battery electrodes, etc., can solve the problems of low powder processing efficiency, poor consistency of finished products, and affecting product quality, so as to improve heat treatment efficiency, Low cost and good product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

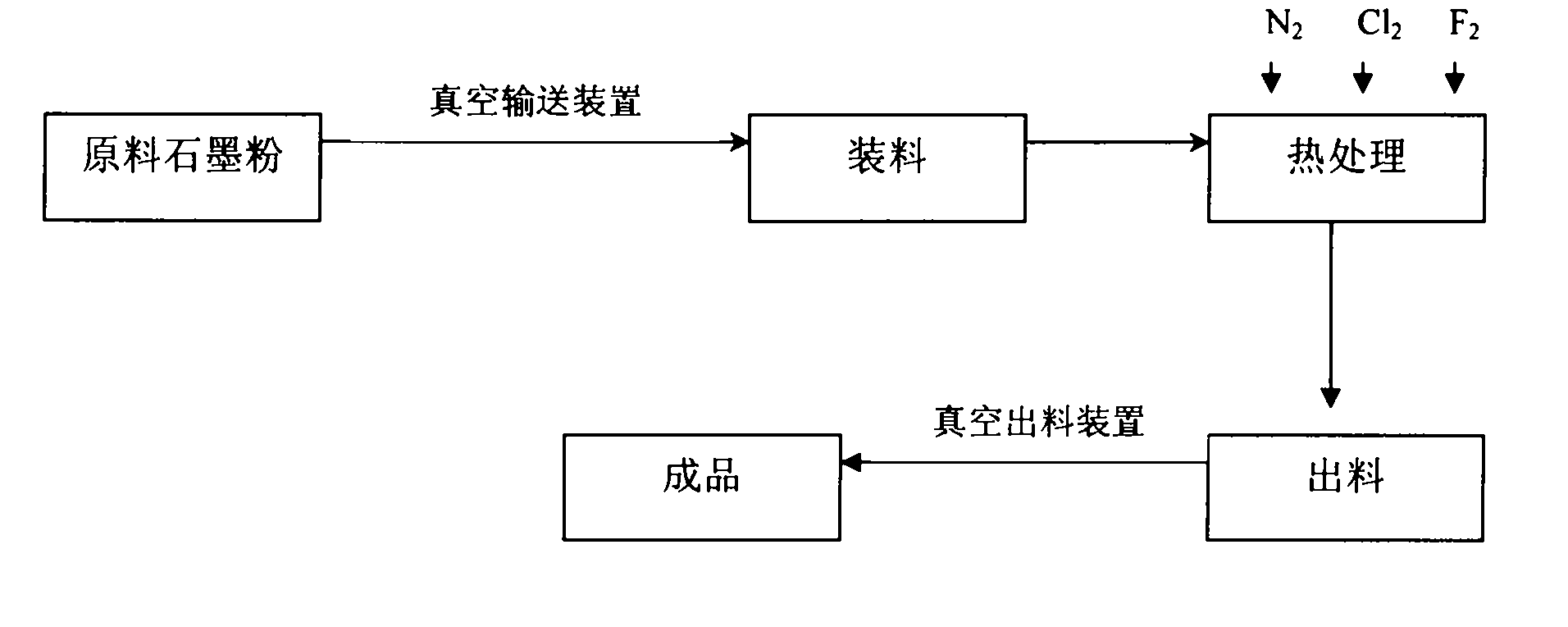

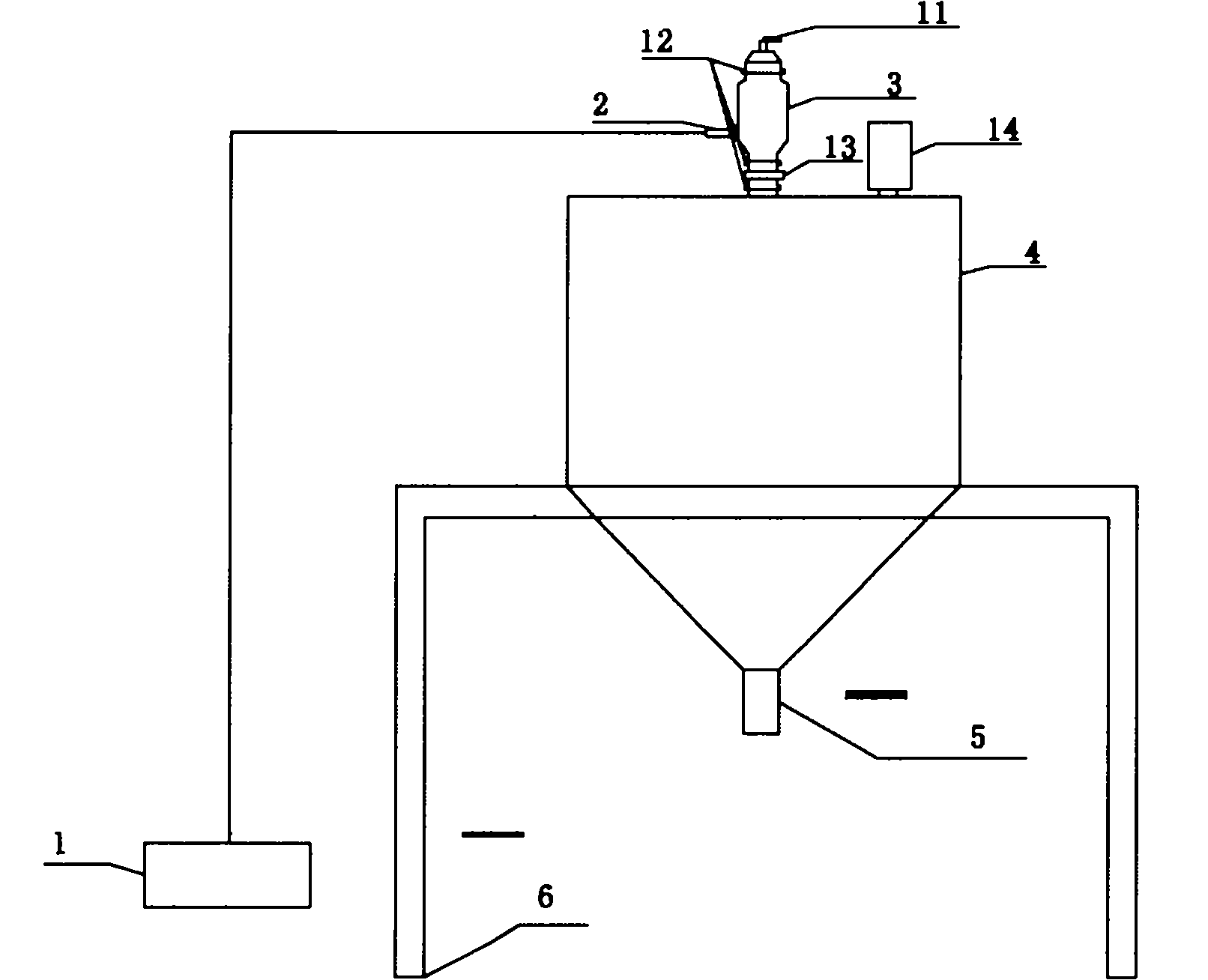

[0022] The preparation method of the graphite powder of the present invention comprises the following steps: 1. The carbon content mass ratio is 85-99.95%, and the tap density Tap value is 0.4-1.2g / cm 3 , the particle size is 0.5-50μm, and the specific surface area SSA is 1.0-12.0m 2 / g, the distance d between the ink sheet 002 0.3354~0.3470nm, Fe content 50~4000ppm, magnetic substances Co, Ni and their alloys, alloys of Co, Ni and Fe, iron oxide 1~300ppm, natural graphite powder with a pH value of 5.5~7.5, artificial Graphite powder, needle coke powder, petroleum coke powder, high-temperature pitch or mesophase carbon microspheres are vacuum transported into the graphite crucible, and then the graphite crucible is sealed with a graphitizable binder; The graphite crucible is put into the graphitization furnace. The graphitization furnace is an Aiqisun graphitization furnace (AQX-3300 type of Taiyuan Zhongjin Carbon Co., Ltd.), an in-line graphitization furnace or a continuous...

Embodiment 1

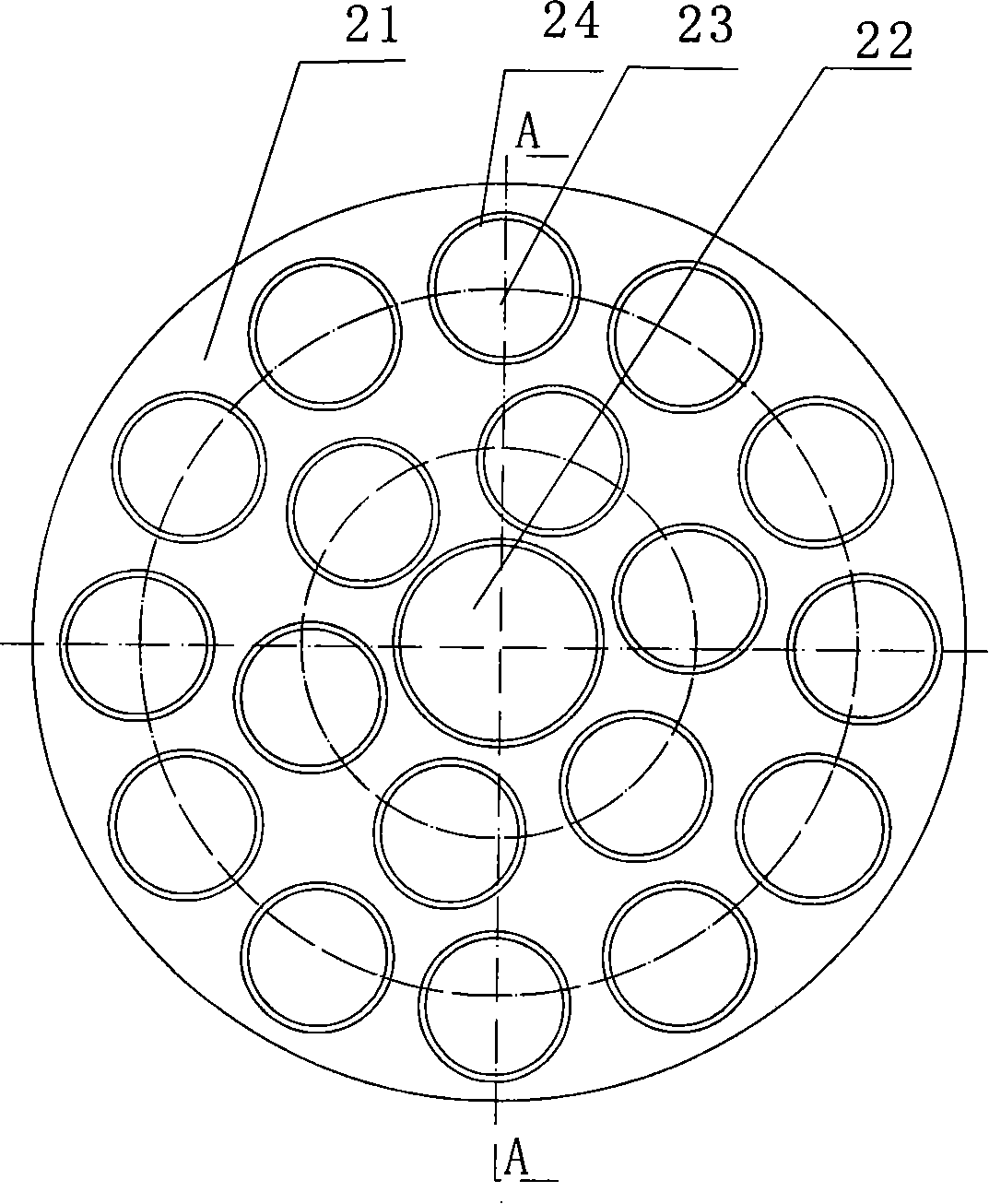

[0026] Example 1, the natural graphite powder is packed into a graphite crucible through a vacuum conveying system. The graphite crucible is a graphite material structure, and one end is provided with a sealable end cap, and the other end is closed. There are 9 graphite crucible cross-sections arranged in a honeycomb shape The diameter of the hole is 200mm, the depth of the hole is 300mm, and the wall thickness between the holes is 20mm. And sealed with graphitizable pitch, the purity of natural graphite powder before treatment is: fixed carbon content 99%, tap density Tap value 0.95g / cm 3 , average particle size 10μm, specific surface area SSA: 4.5m 2 / g,d 002: 0.3358nm, Fe content: 1000ppm, magnetic substances Ni, Cr and Zn: 200ppm, pH value: 6.5. Graphitization heat treatment is carried out in an internal series graphitization furnace, with a heating rate of 1.3°C / min, the heat treatment temperature is 2800°C, the flow rate of nitrogen gas is 80 ml / min during the graphiti...

Embodiment 2

[0027] Example 2, the natural graphite powder is packed into a graphite crucible through a vacuum conveying system. The graphite crucible is a graphite material structure, and one end is provided with a sealable end cap, and the other end is closed. There are 20 cross-sections of the graphite crucible arranged in a honeycomb shape. The square hole, the side length of the hole is 100mm, the hole depth is 200mm, and the wall thickness between the holes is 20mm. And sealed with graphitizable pitch, the purity of graphite powder before treatment is: fixed carbon content 98%, tap density Tap value 0.9g / ml, average particle size 50μm, specific surface area SSA: 1.0m 2 / g;d 002 : 0.3356nm, Fe content: 50ppm, magnetic substance Ni, Cr and Zn: 100ppm, pH value: 6.5. The Acheson graphitization furnace is used for graphitization heat treatment. During the graphitization process, the flow rate of nitrogen gas is 500 ml / min, the heating rate is 10°C / min, and the heat treatment temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com