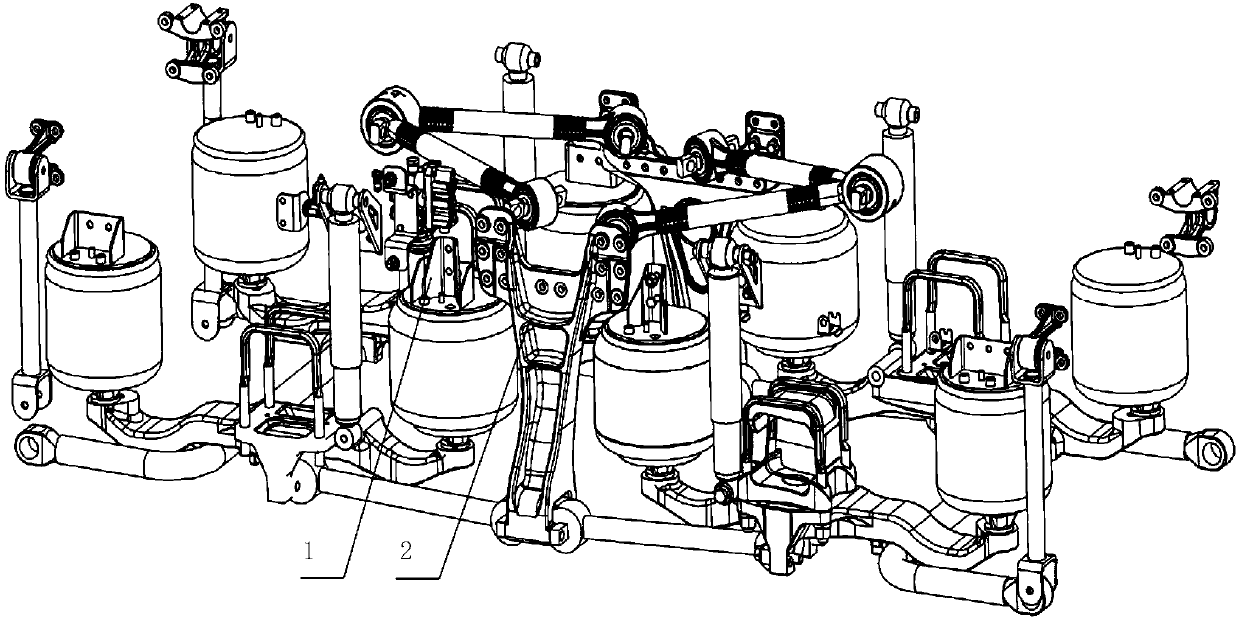

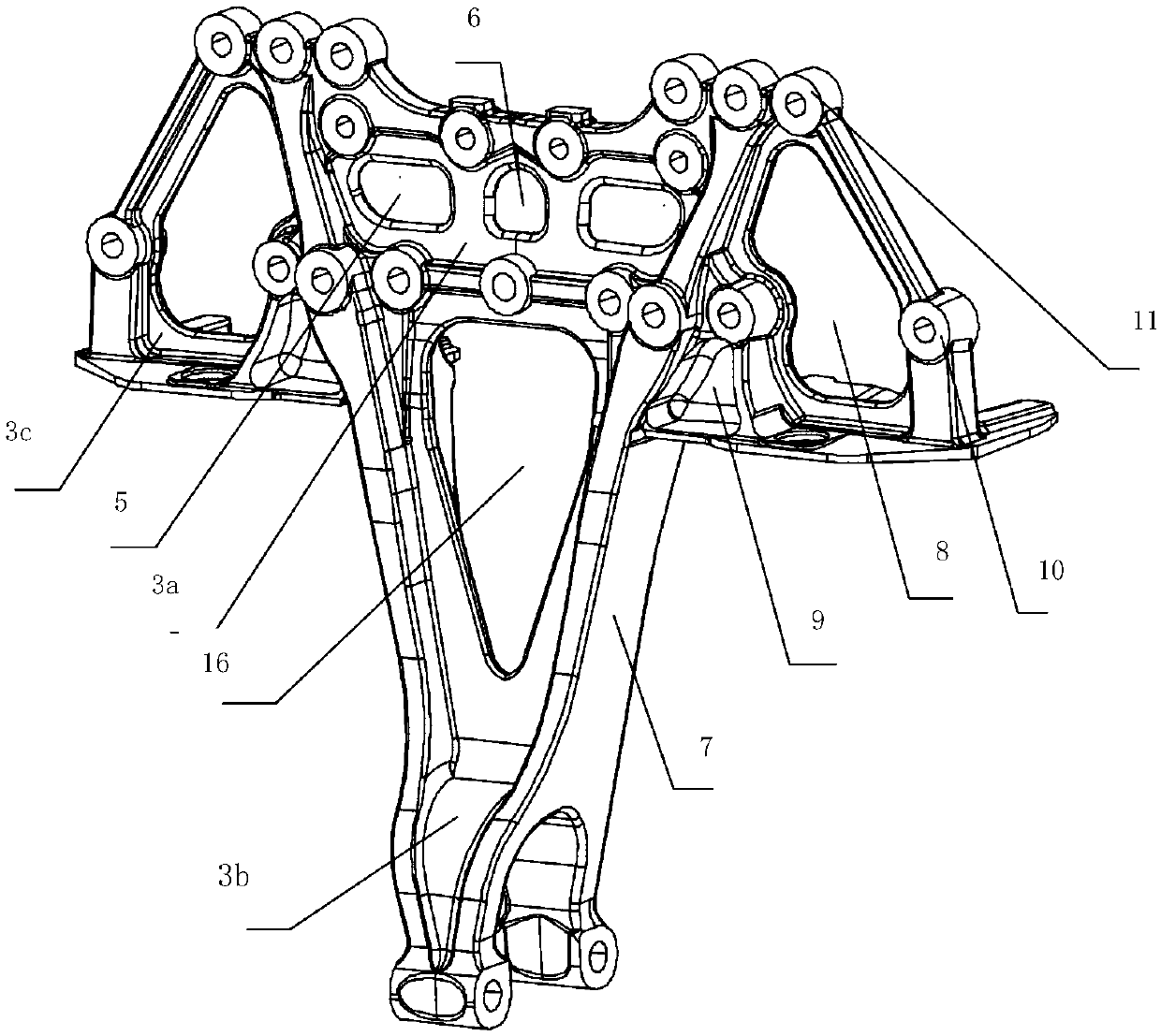

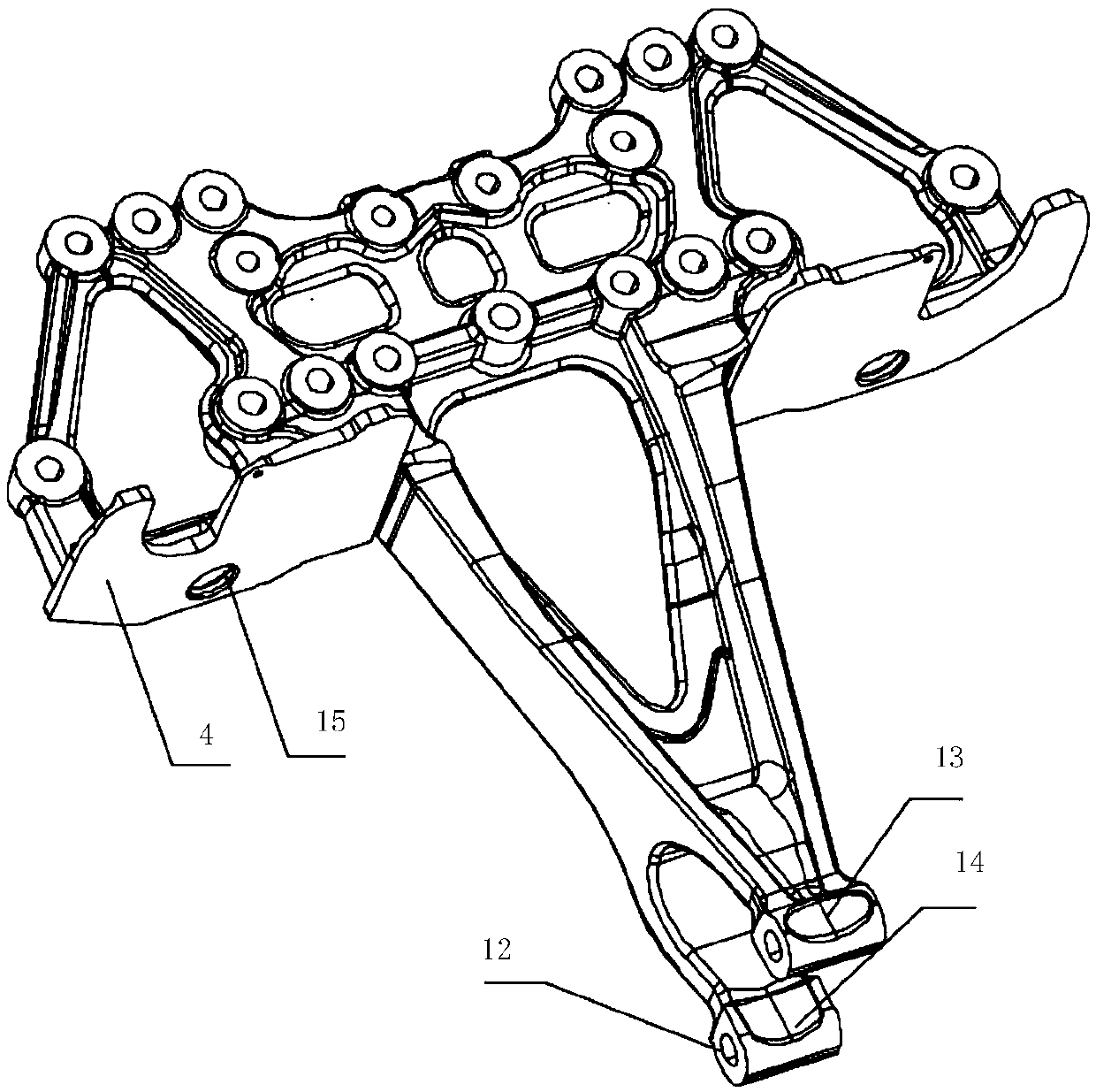

A functionally integrated bracket for an air suspension

An air suspension and functional technology, applied in suspension, elastic suspension, transportation and packaging, etc., can solve problems such as abnormal movement of the system, high scrap rate, and difficult casting, so as to improve fuel economy, cost and The effect of reducing time and ensuring effective strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment is a cast ductile iron with high yield strength and high toughness, the weight percentage of its chemical composition is: C: 2.94%, S: 0.022%, P: 0.019%, Mn: 0.3%, Si: 4.4%, Cr : 0.16%, Mg: 0.04%, Re: 0.03%, and the rest is Fe.

[0024] The above materials are prepared by sand casting through batching, electric furnace smelting and spheroidizing inoculation. The production method is as follows:

[0025] Step 1: Proportion pig iron, steel scrap and other required alloy ingredients according to the given chemical composition ratio;

[0026] Step 2: Put the prepared material into the electric furnace for melting;

[0027] Step 3: Add spheroidizing inoculant during the smelting process, pour into the prepared sand mold after the spheroidizing inoculation time is satisfied, and after cooling and forming, the casting of the required material is obtained:;

[0028] Step 4: Attach the above-mentioned casting to the test bar for tensile properties. The average ...

Embodiment 2

[0030] This embodiment is a cast ductile iron with high yield strength and high toughness. The weight percentage of its chemical composition is: C: 3.72%, S: 0.01%, P: 0.04%, Mn: 0.35%, Si: 2.2%, Cr : 0.18%, Mg: 0.02%, Re: 0.01%, and the rest is Fe.

[0031] The above materials are prepared by sand casting through batching, electric furnace smelting, spheroidizing and inoculating. Its production method is:

[0032] Step 1: Proportion pig iron, steel scrap and other required alloy ingredients according to the given chemical composition ratio;

[0033] Step 2: Put the prepared material into the electric furnace for melting;

[0034] Step 3: Add spheroidizing inoculant during the smelting process, and pour the prepared sand mold after the spheroidizing inoculation time is satisfied. After cooling and forming, the casting of the required material is obtained.

[0035] Step 4: Attach the above-mentioned casting to the test bar for tensile properties. The average results are as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com