A zirconium-cerium alloy gray iron casting

A technology of cast iron and gray cast iron, which is applied in the field of zirconium-cerium alloy gray iron casts, can solve the problems of gray iron casts such as easy fracture, and achieve high tensile/flexural strength, small aspect ratio of edge passivation, and good processability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

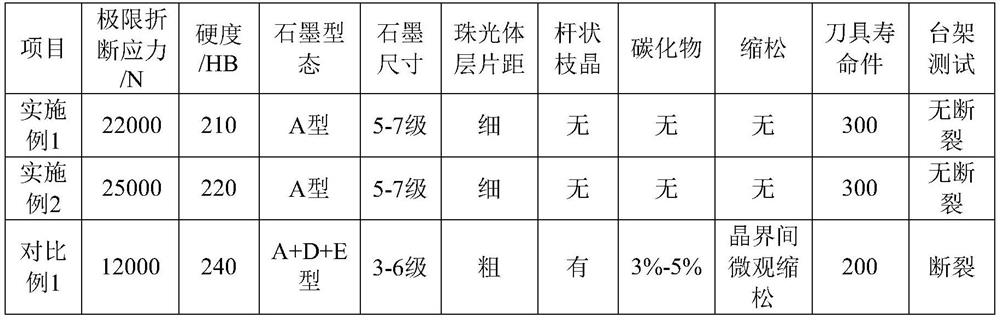

Examples

Embodiment 1

[0037] This embodiment is a zirconium-cerium alloy gray iron casting, which is composed of the following components by weight: 3.45% carbon, 2.0% silicon, 0.8% manganese, 0.06% phosphorus, 0.12% sulfur, and 0.8% copper , tin is 0.06%, chromium is 0.25%, zirconium is 0.05%, cerium is 0.06%, and the balance is iron and inevitable impurities associated with casting. Its production process includes the following steps:

[0038] Step 1) Ingredients: 10% pig iron, 40% thick plate scrap (≥10mm), 50% return charge, medium nitrogen calcined coke recarburizer (N content ≤6000ppm, particle size 1-5mm) 1.2%, ferrosilicon 1.5%, 1% ferromanganese, 0.15% iron sulfide, 0.8% copper, 0.06% tin, 0.3% ferrochromium, 0.5% ferrozirconium;

[0039] Step 2) Feeding and melting: first add 8% pig iron to the bottom of the electric furnace, add 20% scrap steel and 0.6% recarburizer, then add 20% return charge, after the electric furnace is full, start the melting by power transmission at maximum power,...

Embodiment 2

[0048] This embodiment is a zirconium-cerium alloy gray iron casting, which is composed of the following components by weight percentage: carbon is 3.30%, silicon is 2.2%, manganese is 0.7%, phosphorus is 0.1%, sulfur is 0.08%, and copper is 0.6% , tin is 0.04%, chromium is 0.15%, zirconium is 0.03%, cerium is 0.03%, and the balance is iron and inevitable impurities associated with casting. Its production process includes the following steps:

[0049] Step 1) Ingredients: 10% pig iron, 40% thick plate scrap (≥10mm), 50% return charge, medium nitrogen calcined coke recarburizer (N content≤6000ppm particle size 1-5mm) 1.1%, ferrosilicon 1.5%, manganese Iron 1%, iron sulfide 0.15%, copper 0.6%, tin 0.04%, ferrochromium 0.2%, iron zirconium 0.3%;

[0050] Step 2) Feed melting: first add 10% pig iron to the bottom of the electric furnace, add 20% scrap steel and 0.6% recarburizer, then add 20% return charge, and start the maximum power transmission and melting after filling the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com