Flame retardant reinforced co-polymerized nylon composite with high temperature of glowing filaments and preparation technology thereof

A technology of copolymerized nylon and high glow wire is applied in the field of modified engineering plastics, which can solve the problems of easy cracking, brittleness, inability to meet material performance requirements, etc., and achieve the effect of good impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

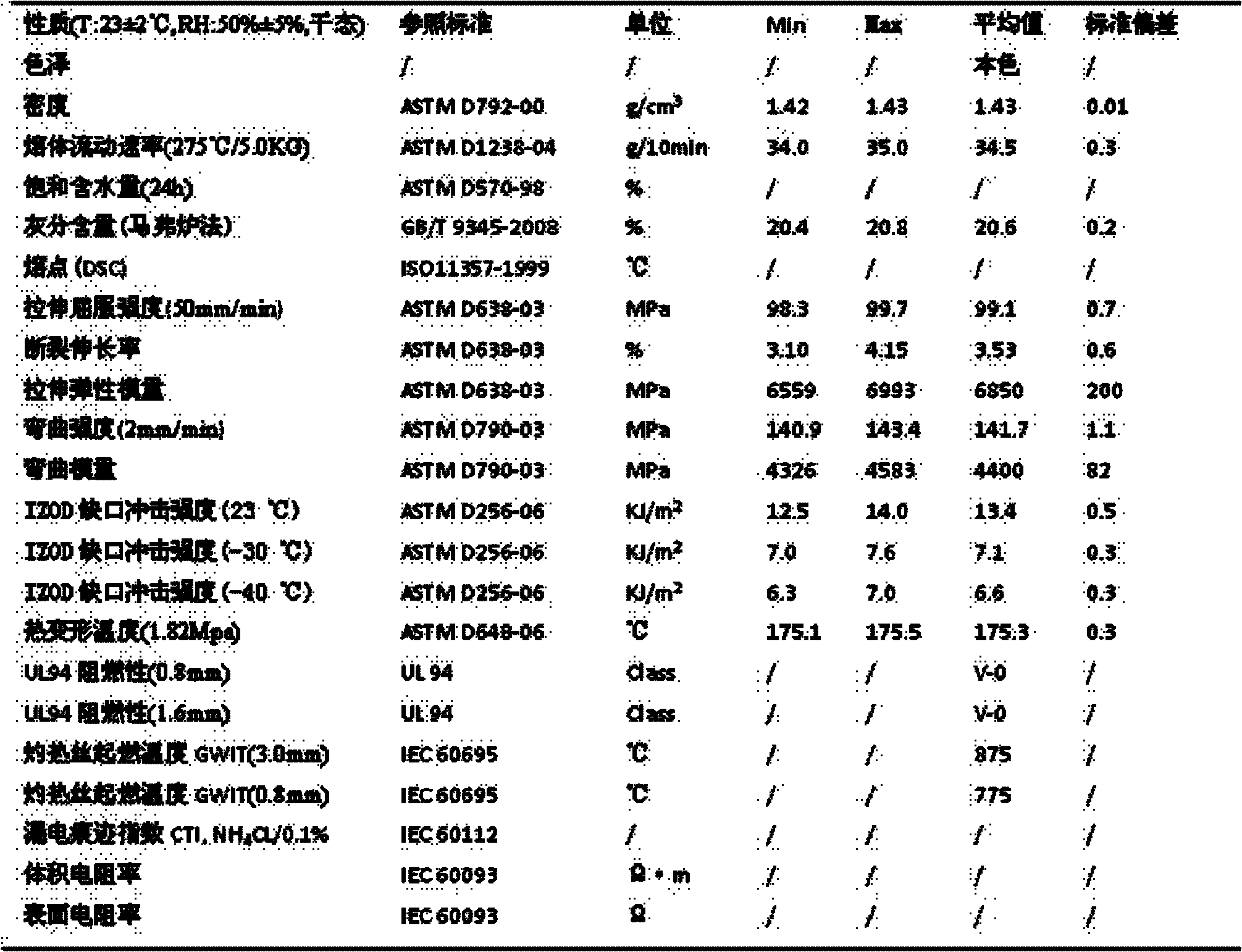

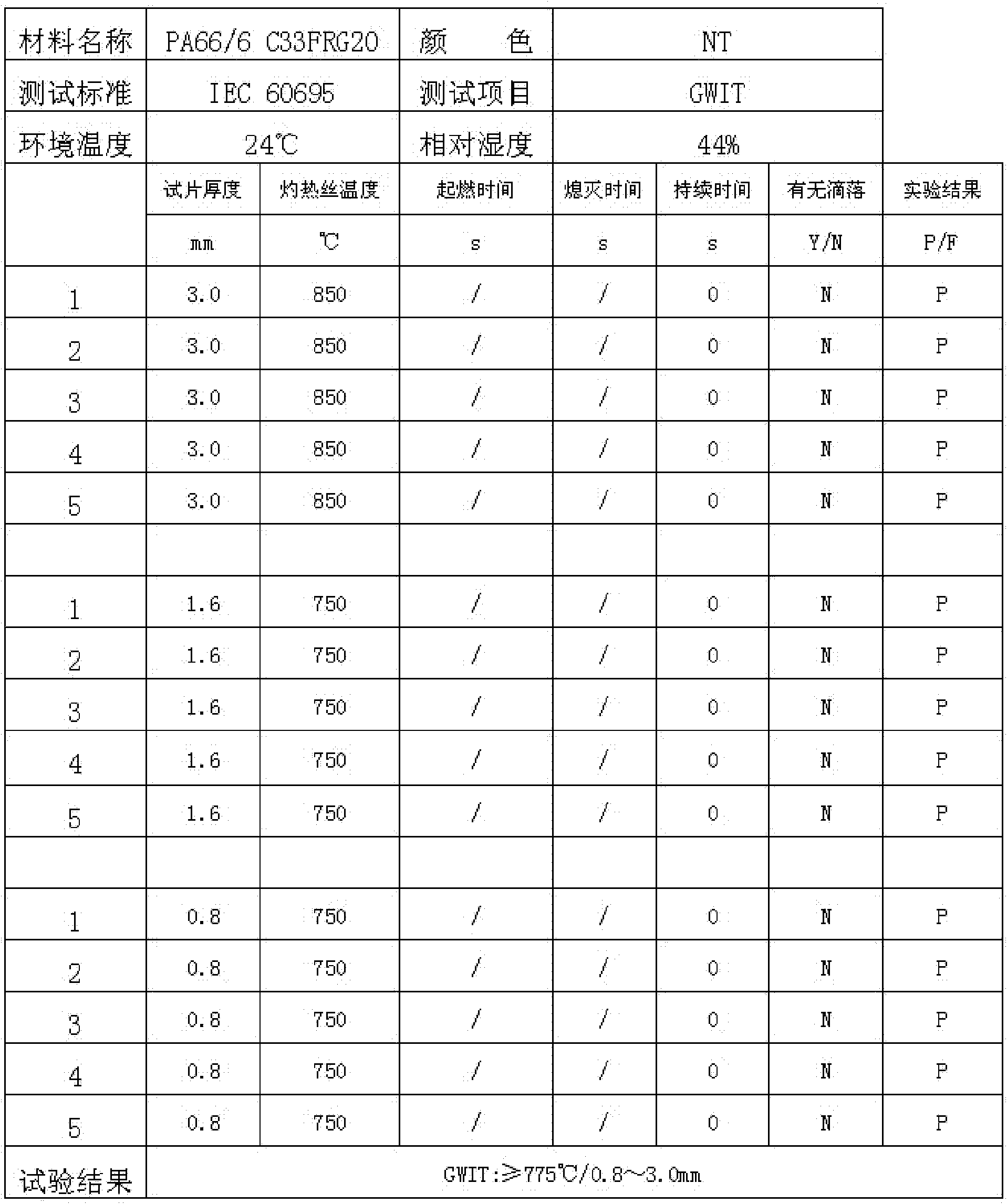

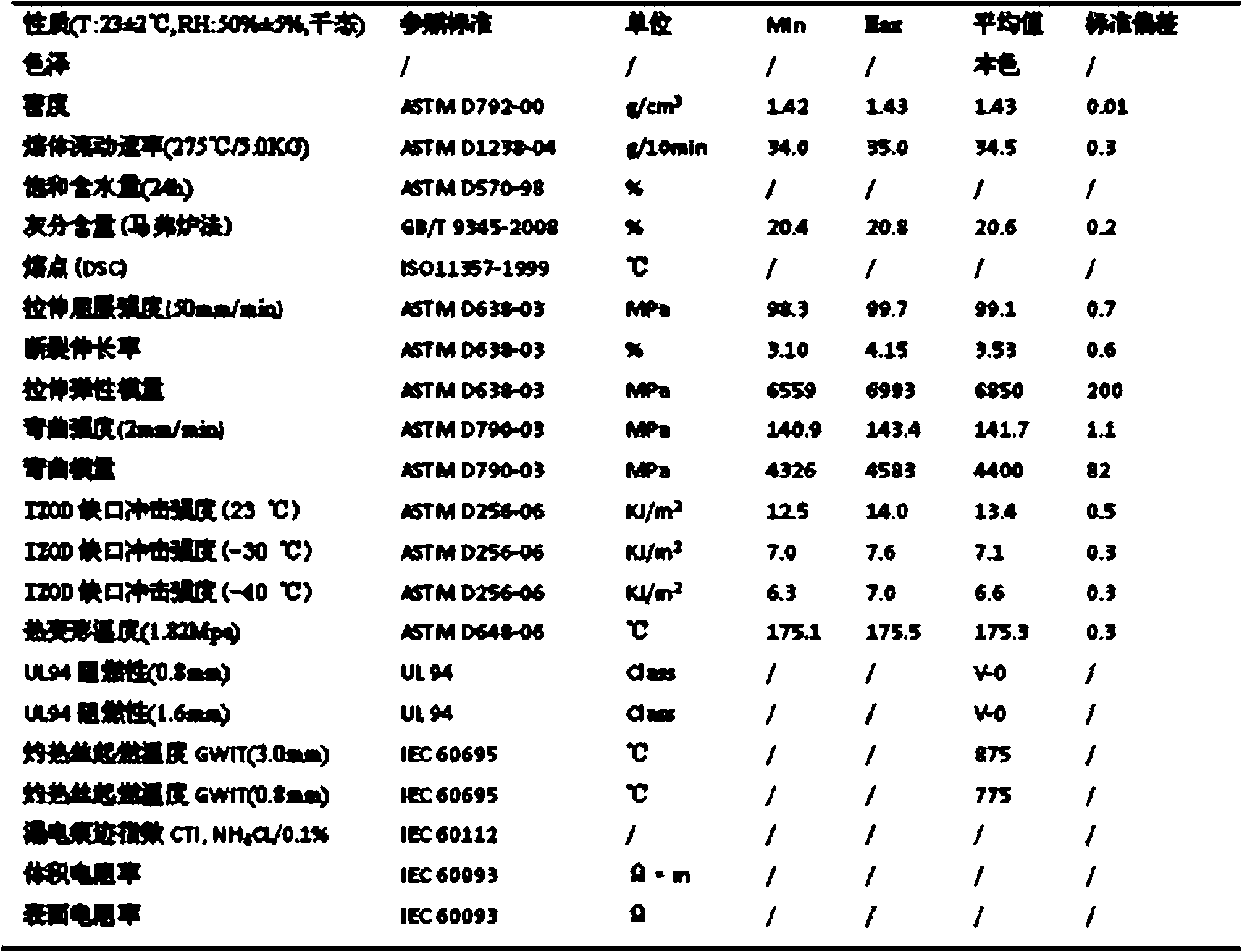

Image

Examples

Embodiment

[0034] 1. Raw materials:

[0035] ①PA66 / 6: C33, BASF, Germany

[0036] ②Polybrominated styrene: PBS-64HW, American Great Lakes Company

[0037] ③ Antimony trioxide: Yunnan Muli Antimony Industry Co., Ltd.

[0038] ④Layered double hydroxyl composite metal oxide (magnesium aluminum carbonate hydrotalcite): AC-106, Guangzhou Chenghe Technology Co., Ltd.

[0039] ⑤PTFE: A100, Sichuan Chenguang Chemical Research Institute

[0040] ⑥Alkali-free glass fiber: T635C, Taishan Glass Fiber Co., Ltd.

[0041] 2. Equipment and instruments:

[0042] ① Co-rotating twin-screw extruder: SHJ-65B, Nanjing Guangda Chemical Equipment Co., Ltd.

[0043] ② Melt flow rate meter: XNR-400, Chengde Jinjian Testing Instrument Co., Ltd.

[0044] ③Tracking tester: LDQ-2, Shanghai Microelectronics Technology Co., Ltd.

[0045] ④Horizontal and vertical combustion tester: HVL-75, Shanghai Ai Microelectronics Technology Co., Ltd.

[0046] ⑤ Glow wire tester: ZRF-JT, Shanghai Jingtian Electronic Techno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com