Polypropylene composite material with spraying-free and high-rigidity metal texture effect and preparation method thereof

A metal texture and composite material technology, applied in the field of polypropylene composite materials and its preparation, can solve the problems of affecting product appearance, high addition ratio, high cost, etc., to provide metallic luster effect, improve dispersion performance, and solve the problem of weld lines Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

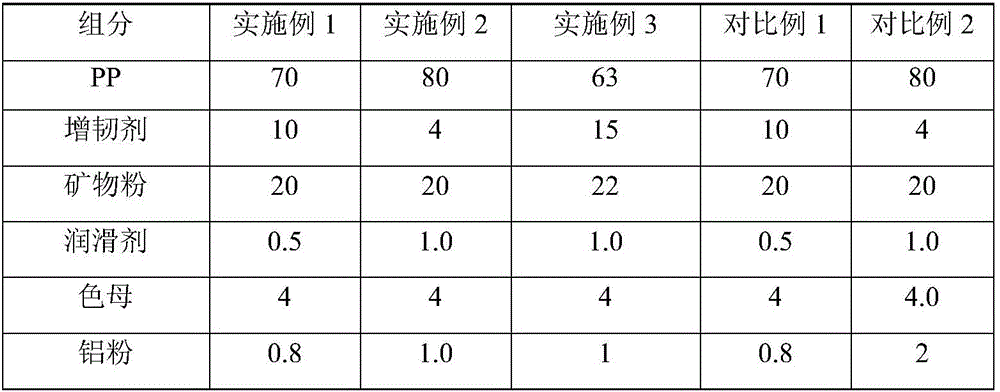

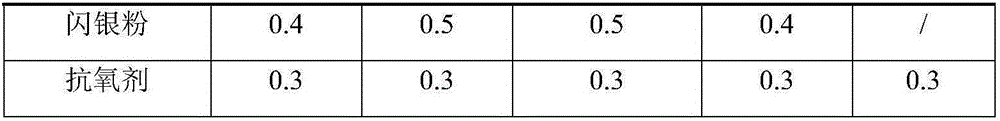

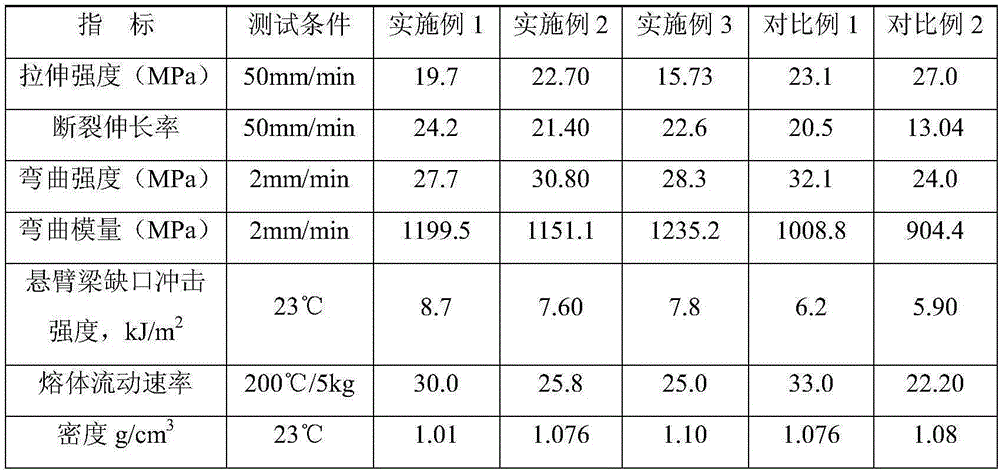

[0043] Example 1 Preparation of Spray-free, High Rigid Metal Texture Effect PP Composite Material

[0044] According to the raw material formula in Table 1, various raw materials were weighed, among which PP resin (under the condition of 200°C / 10kg, its melt index was 35g / 10min, and its specific gravity was 0.905g / cm 3 ), mineral powder (mica powder, mesh number 1500-2000 mesh, treated with polypropylene-maleic acid acyl graft, wherein the addition of polypropylene-maleic acid acyl graft is 2%) and toughening agent POE (specific gravity 0.86-0.91g / cm 3 , melt index>1g / 10min, elongation at break>900%).

[0045] Before use, add mineral powder, aluminum powder, silver flash powder, antioxidant, and special dimethyl silicone oil in sequence, and stir at a low speed for 1-3 minutes, then add PP resin, toughener, and color masterbatch, and stir at a low speed for 2-5 minutes Then stir at a high speed (650-1300rpm) for 3-5 minutes; the mixed material is melted and granulated to obt...

Embodiment 2、3

[0051] Embodiment 2,3 Preparation of spray-free, high-rigidity metal texture effect PP composite material

[0052] The preparation methods of Examples 2 and 3 are the same as in Example 1, and the specific raw material ratios are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com