High-hardness wear-resistant copper alloy for plastic mould and preparation method thereof

A plastic mold, high hardness technology, applied in the field of alloy materials, can solve problems such as high and no more than 160HV, and achieve the effect of improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] A kind of preparation method of high-hardness wear-resistant copper alloy for plastic mould, raw material Mo powder, Cr powder, copper powder particle size all are 200 orders, and purity is 99%, and concrete technological process is as follows:

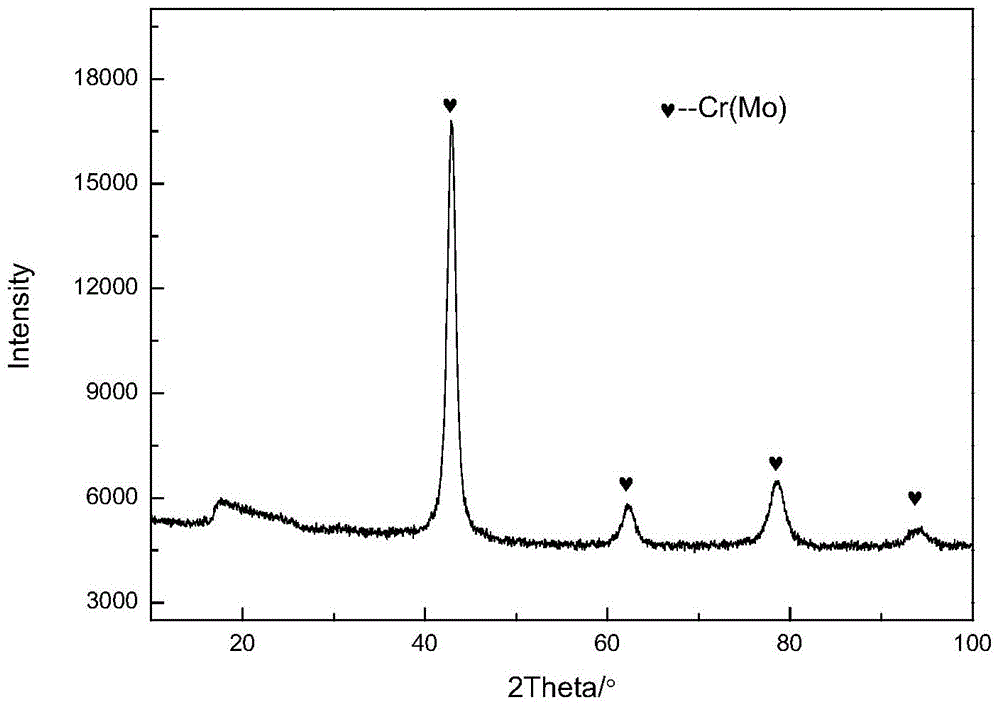

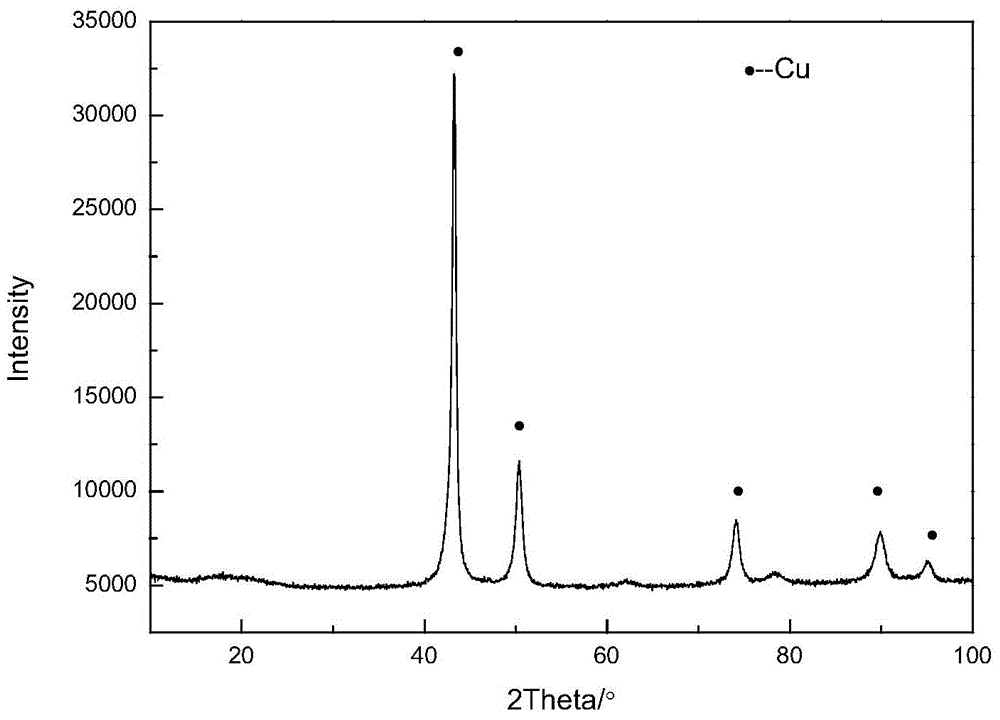

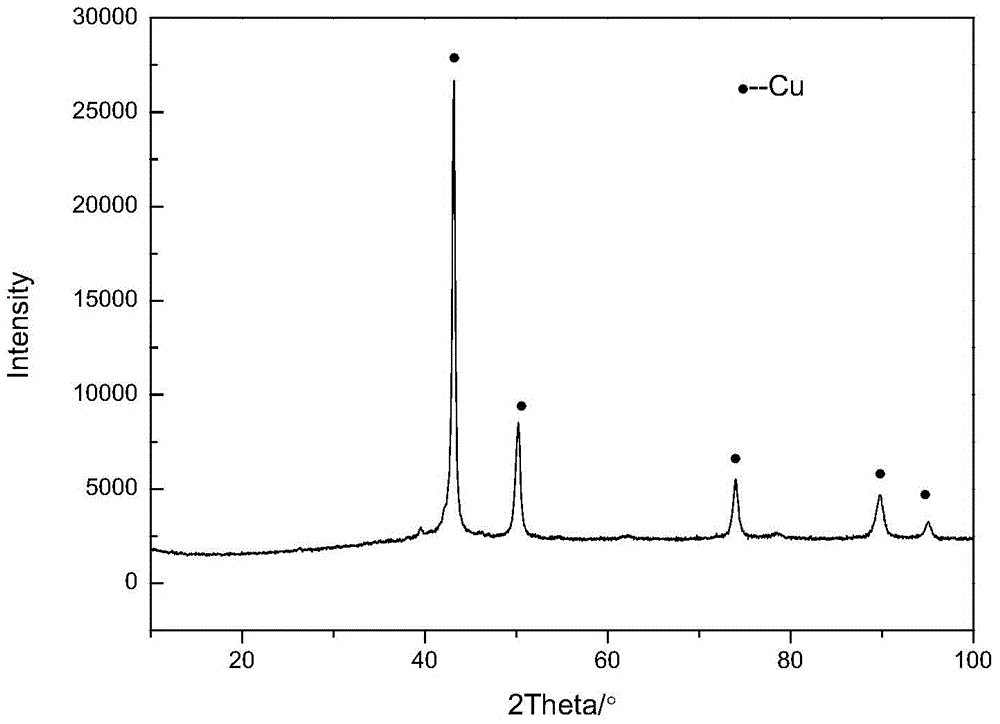

[0035] 1. Evenly mix the raw material Mo powder and Cr powder according to the mass ratio of 1:1, and mechanically grind on a vibrating rod mill for 16 hours to obtain high-energy Cr(Mo) pre-alloyed solid solution powder. During the grinding process, the grinding tank is vacuumed Protected by an argon atmosphere, dry grinding and wet extraction are adopted after grinding to ensure that the powder is not oxidized during the whole process, and then dried in a vacuum drying oven (70-80°C) for use; by figure 1 It can be seen that the Mo peak and the Cr peak no longer exist in the XRD results, and only the Cr(Mo) solid solution peak is displayed, indicating that the solid solution process of Mo and Cr has been realized, and a high-en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com