Aluminum alloy material and production process thereof

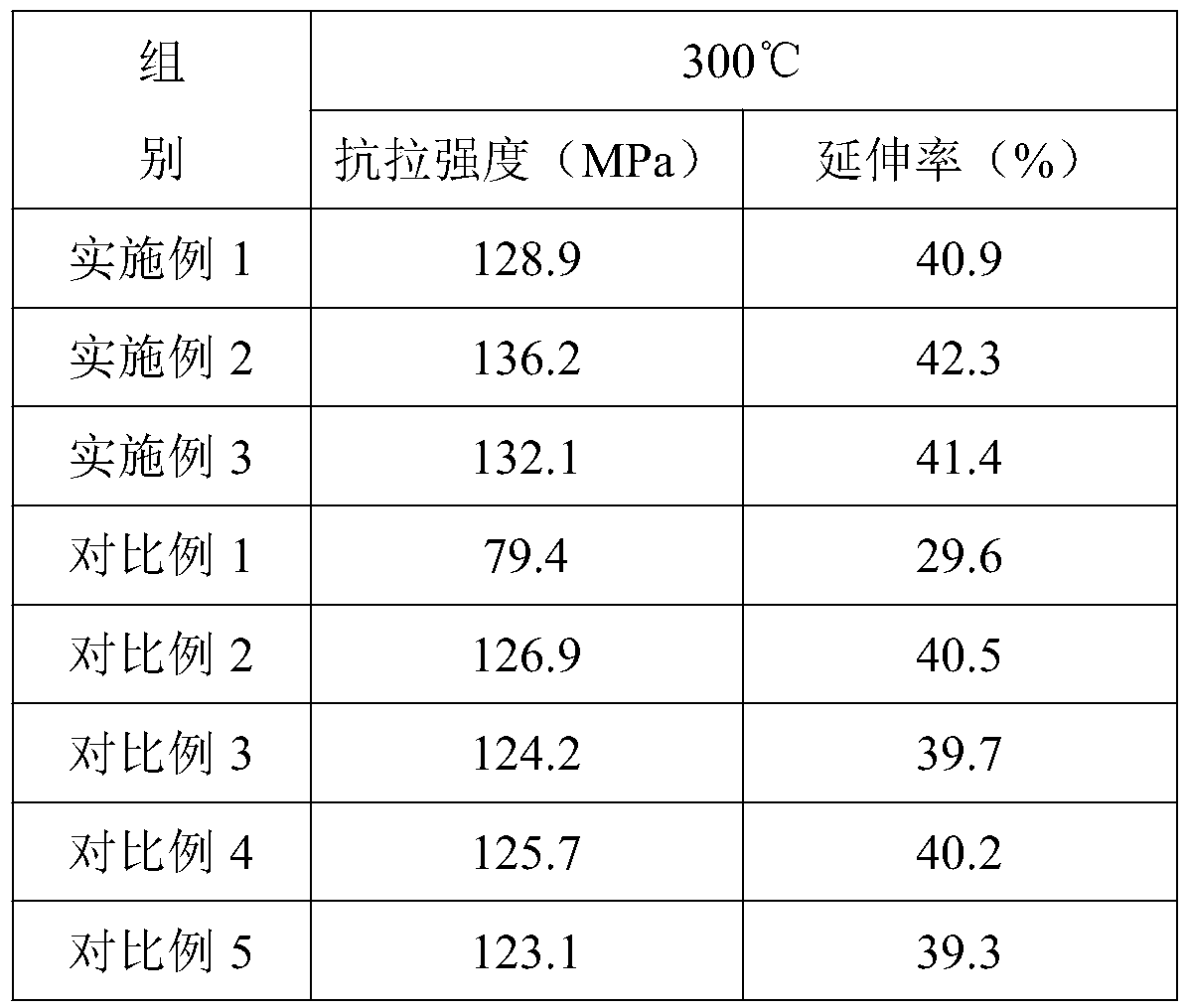

An aluminum alloy material and production process technology, applied in the field of aluminum alloy production, can solve the problems of poor tensile strength and elongation, and achieve the effect of improving the tensile strength and elongation index and meeting the material performance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An aluminum alloy material, in parts by weight, comprising the following raw materials: 105 parts of aluminum ingot, 2.8 parts of magnesium ingot, 1.6 parts of aluminum-silicon alloy, 0.6 part of copper block, 2.3 parts of zinc block, 0.3 part of iron block, 0.5 part of manganese block 0.2 parts of magnesium lanthanum alloy, 0.1 part of dysprosium powder, 0.2 part of aluminum neodymium alloy, 0.1 part of magnesium holmium alloy, 2.4 parts of molybdenum powder, 5 parts of chromium powder, 1.1 part of vanadium powder, 0.04 part of erbium powder, 2.6 parts of silicon carbide, 0.2 parts of refining agent;

[0033] The refining agent includes the following raw materials in parts by weight: 10 parts of sodium aluminum fluoride, 3 parts of potassium chloride, and 4 parts of calcium sulfide;

[0034] The production process of the aluminum alloy material comprises the following steps:

[0035] (1) Aluminum ingot, magnesium ingot, aluminum silicon alloy, copper block, zinc block...

Embodiment 2

[0040] An aluminum alloy material, in parts by weight, comprising the following raw materials: 115 parts of aluminum ingot, 3.2 parts of magnesium ingot, 1.8 parts of aluminum-silicon alloy, 0.9 part of copper block, 3 parts of zinc block, 0.5 part of iron block, and 0.7 part of manganese block 0.4 parts of magnesium lanthanum alloy, 0.1 part of dysprosium powder, 0.3 parts of aluminum neodymium alloy, 0.1 part of magnesium holmium alloy, 2.8 parts of molybdenum powder, 7 parts of chromium powder, 1.4 parts of vanadium powder, 0.06 parts of erbium powder, 3.4 parts of silicon carbide, 0.2 parts of refining agent;

[0041] The refining agent includes the following raw materials in parts by weight: 15 parts of sodium aluminum fluoride, 4 parts of potassium chloride, and 6 parts of calcium sulfide;

[0042] The production process of the aluminum alloy material comprises the following steps:

[0043] (1) Aluminum ingot, magnesium ingot, aluminum silicon alloy, copper block, zinc ...

Embodiment 3

[0048]An aluminum alloy material, in parts by weight, comprising the following raw materials: 121 parts of aluminum ingot, 3.2 parts of magnesium ingot, 2 parts of aluminum-silicon alloy, 1 part of copper block, 3.8 parts of zinc block, 0.6 part of iron block, 0.9 part of manganese block 0.5 parts of magnesium lanthanum alloy, 0.2 parts of dysprosium powder, 0.3 parts of aluminum neodymium alloy, 0.2 parts of magnesium holmium alloy, 3 parts of molybdenum powder, 9 parts of chromium powder, 1.5 parts of vanadium powder, 0.07 parts of erbium powder, 3.4 parts of silicon carbide, 0.3 parts of refining agent;

[0049] The refining agent includes the following raw materials in parts by weight: 17 parts of sodium aluminum fluoride, 4 parts of potassium chloride, and 6 parts of calcium sulfide;

[0050] The production process of the aluminum alloy material comprises the following steps:

[0051] (1) Aluminum ingot, magnesium ingot, aluminum silicon alloy, copper block, zinc block, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com