Acid-resistant ultrahigh-strength steel for deep-sea dynamic flexible vertical pipe and preparation method of acid-resistant ultrahigh-strength steel

A technology of ultra-high-strength steel and flexible risers, applied in the metallurgical field, can solve the problems of high price of stainless steel, inability to apply on a large scale, poor resistance to sulfide stress corrosion cracking, etc., and achieve good fatigue resistance, easy industrial production and preparation. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

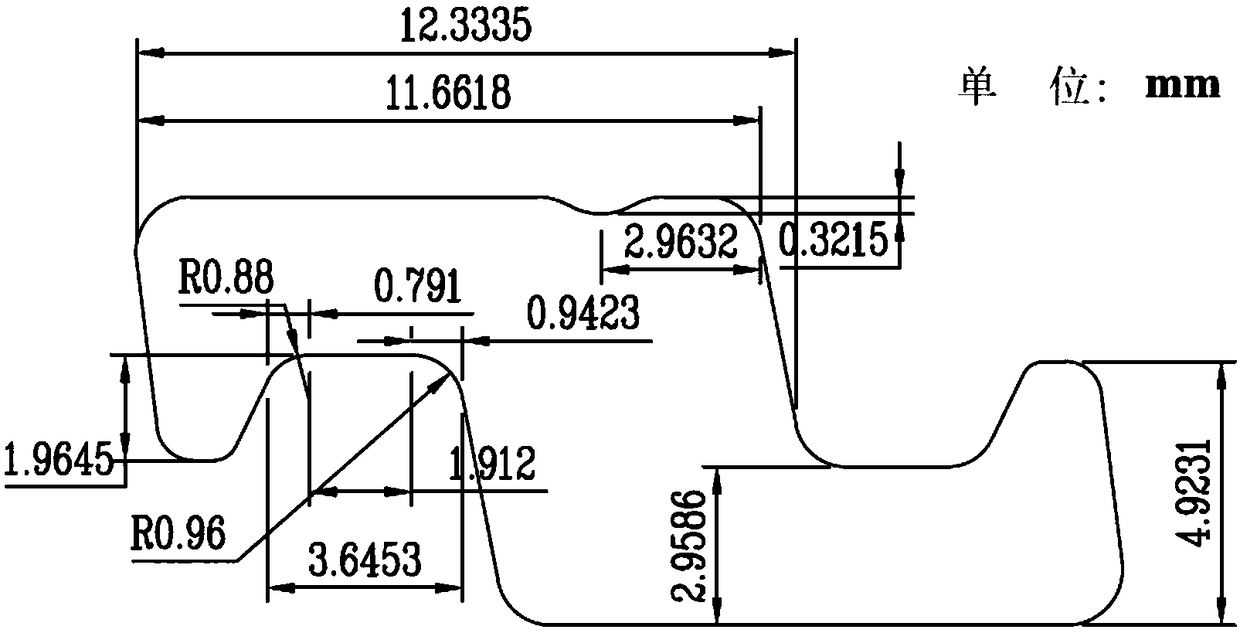

Image

Examples

Embodiment 1

[0039] The ultra-high-strength steel for deep-sea dynamic flexible risers of the present invention has the following chemical composition by weight percentage: C: 0.1%, Si: 0.21%, Mn: 1.4%, P: 0.02%, S: 0.008%, Cr: 2.0%, Mo : 1.5%, Ni: 0.8%, Nb: 0.045%, Ti: 0.018%, the balance is Fe and unavoidable impurities;

[0040] The preparation method of the ultra-high-strength steel for the deep-sea dynamic flexible riser of the present invention is carried out according to the following steps:

[0041] Step 1, casting:

[0042] Smelting, refining and pouring according to the set composition to make a slab, the composition of the slab by weight percentage is: C: 0.1%, Si: 0.21%, Mn: 1.4%, P: 0.02%, S: 0.008%, Cr: 2.0 %, Mo: 1.5%, Ni: 0.8%, Nb: 0.045%, Ti: 0.018%, the balance is Fe and unavoidable impurities;

[0043] Step 2, heating and rolling:

[0044] (1) Heat the billet to 1220°C and keep it warm for 50 minutes to homogenize the structure and composition;

[0045] (2) Using a h...

Embodiment 2

[0052] The ultra-high-strength steel for deep-sea dynamic flexible risers of the present invention has the following chemical composition by weight percentage: C: 0.04%, Si: 0.28%, Mn: 0.4%, P: 0.01%, S: 0.005%, Cr: 0.82%, Mo : 0.83%, Ni: 0.35%, Nb: 0.014%, Ti: 0.011%, the balance is Fe and unavoidable impurities;

[0053] The preparation method of the ultra-high-strength steel for the deep-sea dynamic flexible riser of the present invention is carried out according to the following steps:

[0054] Step 1, casting:

[0055] Smelting, refining and pouring according to the set composition to make a slab, the composition of the slab by weight percentage is: C: 0.04%, Si: 0.28%, Mn: 0.4%, P: 0.01%, S: 0.005%, Cr: 0.82 %, Mo: 0.83%, Ni: 0.35%, Nb: 0.014%, Ti: 0.011%, the balance is Fe and unavoidable impurities;

[0056] Step 2, heating and rolling:

[0057] (1) Heat the billet to 1180°C and keep it warm for 50 minutes to homogenize the structure and composition;

[0058] (2) U...

Embodiment 3

[0065] The ultra-high-strength steel for deep-sea dynamic flexible risers of the present invention has the following chemical composition by weight percentage: C: 0.048%, Si: 0.34%, Mn: 1.04%, P: 0.008%, S: 0.004%, Cr: 1.45%, Mo : 1.18%, Ni: 0.53%, Nb: 0.038%, Ti: 0.014%, the balance is Fe and unavoidable impurities;

[0066] The preparation method of the ultra-high-strength steel for the deep-sea dynamic flexible riser of the present invention is carried out according to the following steps:

[0067] Step 1, casting:

[0068] Smelting, refining and pouring according to the set composition to make a slab, the composition of the slab by weight percentage is: C: 0.048%, Si: 0.34%, Mn: 1.04%, P: 0.008%, S: 0.004%, Cr: 1.45 %, Mo: 1.18%, Ni: 0.53%, Nb: 0.038%, Ti: 0.014%, the balance is Fe and unavoidable impurities;

[0069] Step 2, heating and rolling:

[0070] (1) Heat the billet to 1200°C and keep it warm for 30 minutes to homogenize the structure and composition;

[0071]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com