Method for reducing thickness of tellurium nanosheet

A technology of thickness reduction and tellurium nanometer, applied in the field of nanomaterials, can solve the problems of complex process, complicated operation method, poor sample thinning effect, etc., and achieve the effect of stable development performance, simple operation and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035](1) Preparation of tellurium nanosheets by hydrothermal method: the reaction principle is to use sodium tellurite as raw material, ammonia water provides the alkaline conditions for the reaction, hydrazine hydrate is used to reduce sodium tellurite, and the mirror blocking ligand (PVP) is used to reunite Tellurium nanoparticles, by controlling the amount of PVP added to control the output and size of tellurium nanosheets. The specific operation is to weigh 0.1165g of sodium tellurite and 6.4g of PVP in a molar ratio of 2:1 and dissolve them in 25ml of deionized water. 9, pour the mixed solution into a 50ml reaction kettle, and react at 180°C for 10 hours. After the reaction, quench the reaction kettle with flowing cold water to obtain the stock solution of tellurium nanosheets; take 3 mL of the reaction stock solution and centrifuge it with deionized water for 3 After the second step, uniformly dispersed tellurium nanosheets in the aqueous solution were obtained, and the...

Embodiment 2

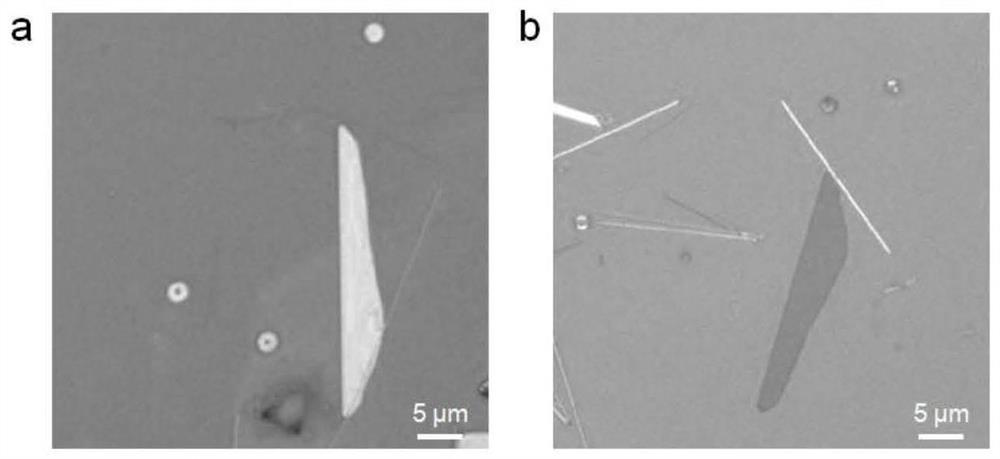

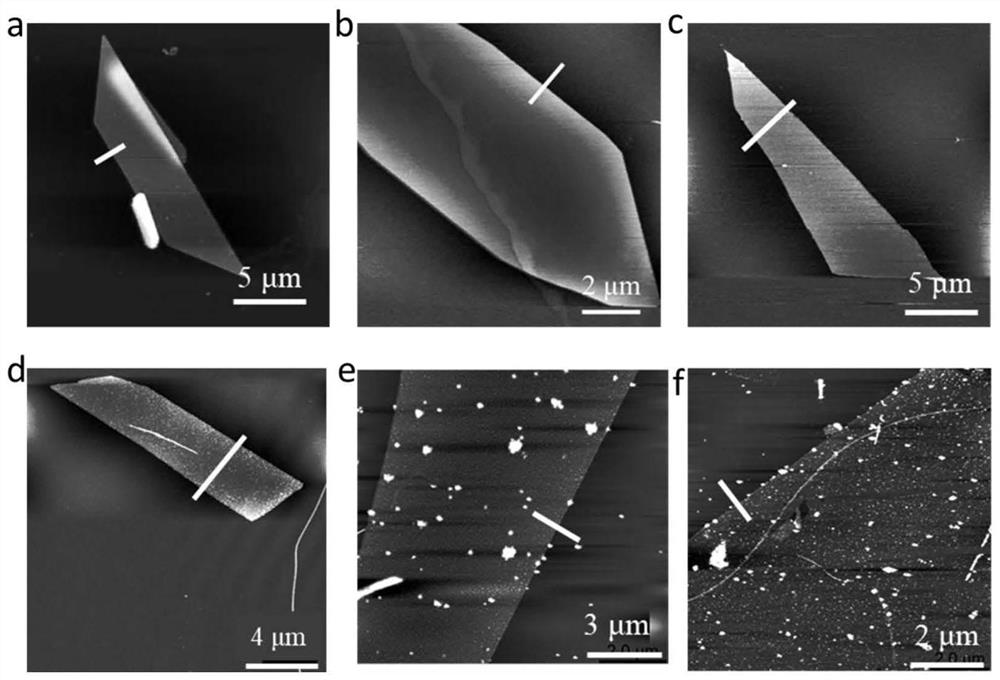

[0041] (1) The preparation method of tellurium nanosheets is the same as step (1) of Example 1, the difference is that the specific operation is to weigh 0.1165g of sodium tellurite and 6.4g of PVP in 25ml of deionized water in a molar ratio of 2:1, and stir After uniformity, add 2.5ml of ammonia water and 4ml of hydrazine hydrate solution and stir evenly, pour the mixed solution into a 50ml reaction kettle, and react at 180°C for 5h. After the reaction, quench the reaction kettle with flowing cold water to obtain tellurium nanosheets Stock solution: Take 3 mL of the reaction stock solution and centrifuge it with deionized water for 3 times to obtain tellurium nanosheets uniformly dispersed in the aqueous solution. Transfer the tellurium nanosheets to an insulating silicon substrate by pulling and pulling method, and dry them naturally at 100°C for 20 minutes. , the thickness of the obtained tellurium nanosheets is 30-50nm.

[0042] (2) Slow thinning of tellurium nanosheets: i...

Embodiment 3

[0045] (1) The preparation method of tellurium nanoplate is the same as embodiment 2 step (1);

[0046] (2) Slow thinning of tellurium nanosheets: immerse the tellurium nanosheets on the insulating silicon substrate obtained in step (1) into an acetic acid solution with a pH of 6 for 20 s. The tellurium nanosheets were soaked in the acetic acid solution for 20s, then quickly taken out and washed with a large amount of deionized water, and then dried with nitrogen to obtain a thin layer of tellurium nanosheets with a single layer to 25nm.

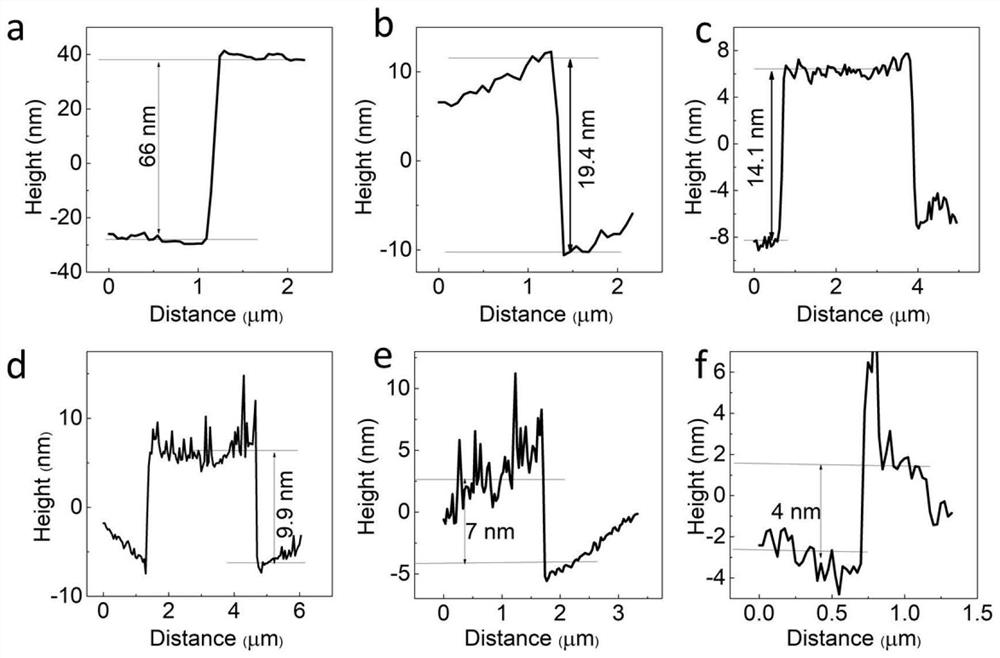

[0047] In order to better compare the morphology changes of the tellurium nanosheets before and after immersion in the acetic acid solution with pH 6, the same piece of tellurium nanosheets was selected for comparison. Figure 5 a, 5b are the AFM morphology characterization of the samples before and after immersion in acetic acid solution with pH 6 for 20s. It can be seen that the morphology of tellurium nanosheets has no obvious change befo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com