Paper pulp molding and pad printing apparatus

A technology of pulp molding and pad printing device, which is applied in the process of adding pulp raw materials, papermaking, textiles and papermaking, etc. It can solve the problems of inconspicuous marks and difficult to distinguish correctly, and achieve good molding and anti-counterfeiting effects, improve precision, The effect of high accuracy of conveying volume control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

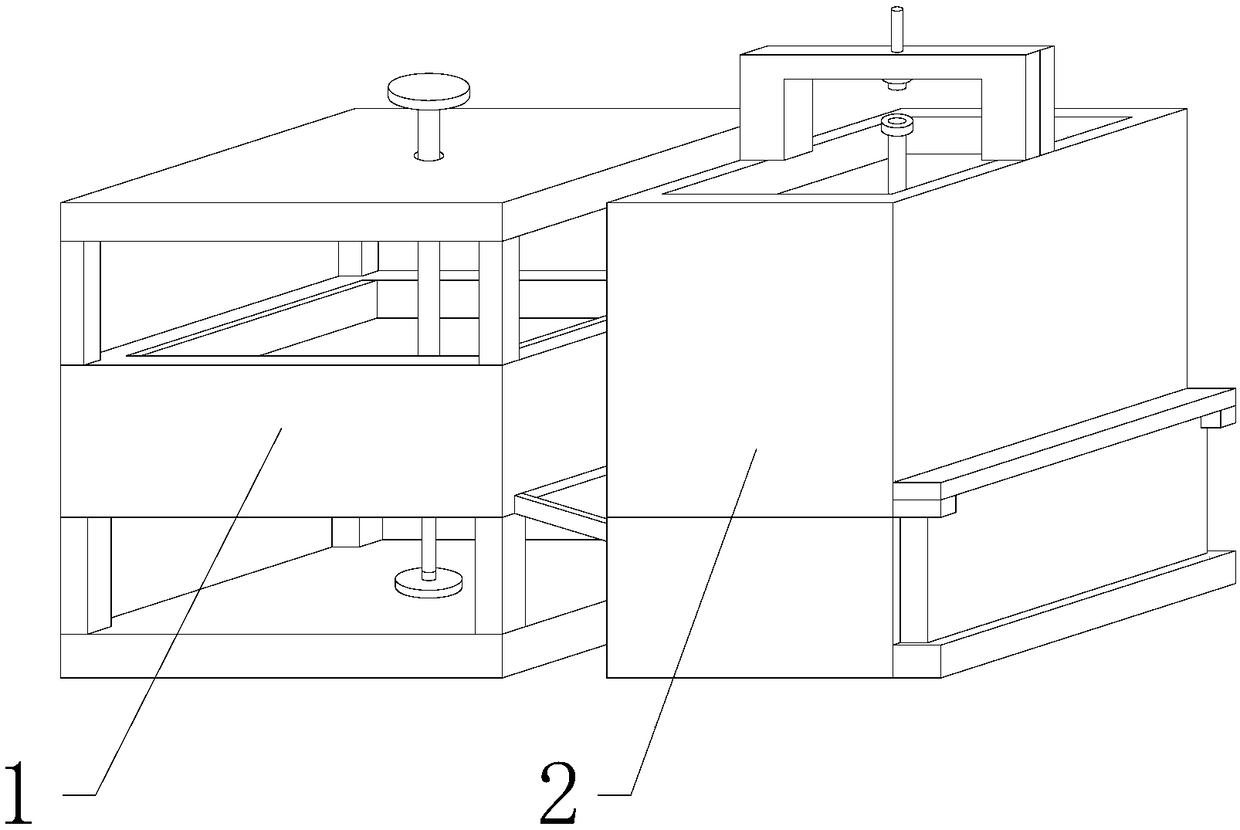

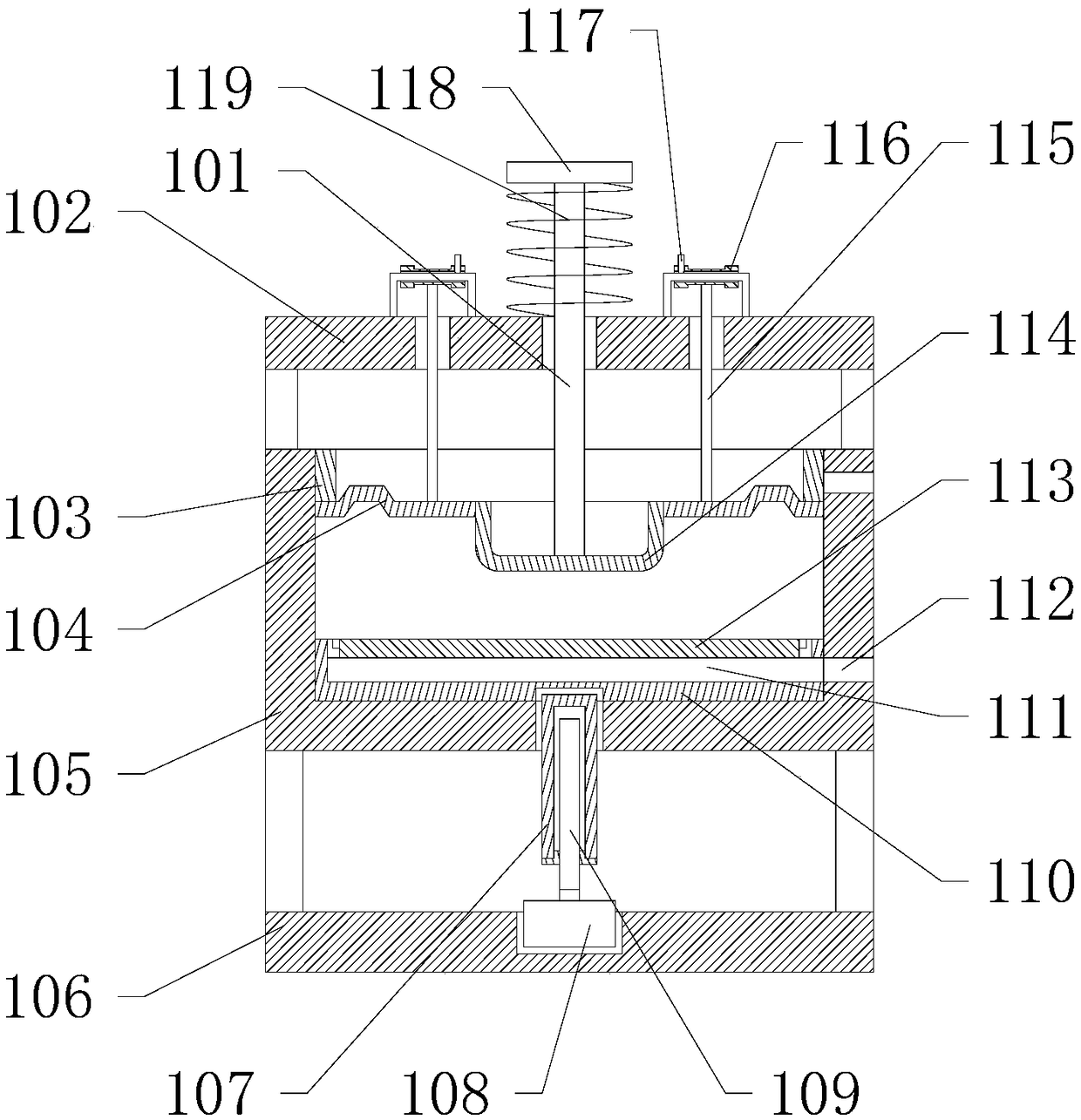

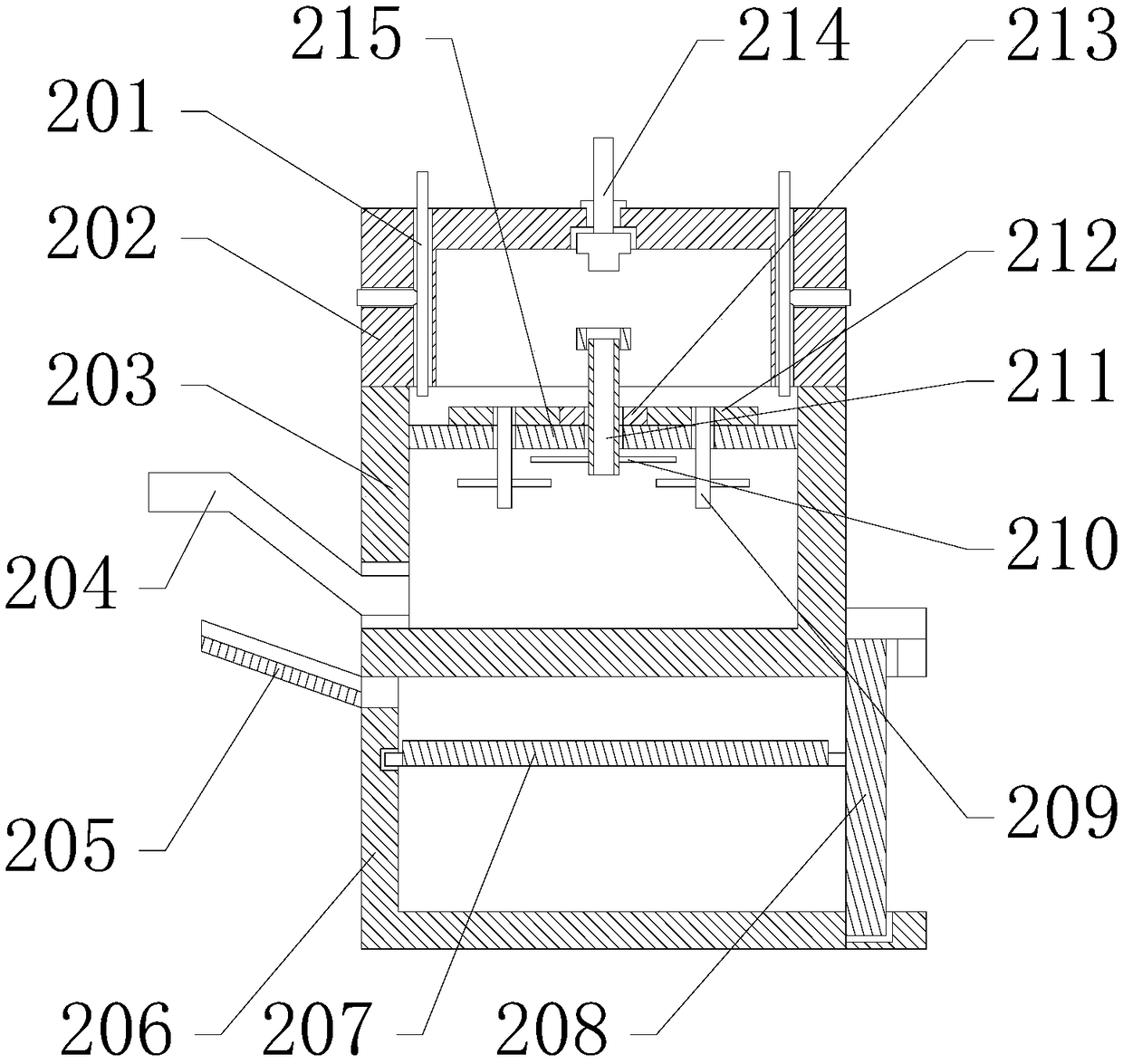

[0032] see Figure 1-Figure 4 , the present invention provides a technical solution: a pulp molding pad printing device, including a forming mechanism 1 and a conveying mechanism 2, the forming mechanism 1 is arranged on the left side of the conveying mechanism 2, and the forming mechanism 1 includes a fixed rod 101, an upper cover 102 , baffle plate 103, outer corrugated plate 104, lower mold base 105, base plate 106, jacking pipe 107, motor 108, screw rod one 109, push plate 110, water storage cavity 111, water outlet tank 112, filter plate one 113, upper Die 114, stay cord 115, reel 116, threaded rod 117, pressing plate 118 and spring 119, conveying mechanism 2 comprises limit bar 201, support frame 202, mixing box 203, conveying inclined pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com