Turbulence fluctuation type stirring device for mixing water-based zinc-rich coating

A stirring device and wave-type technology, which is applied in the field of turbulent flow wave-type stirring devices for water-based zinc-rich paint mixing, can solve the problems of slow mixing speed, low efficiency, and unfavorable efficient production and processing of enterprises, so as to improve mixing efficiency and uniformity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

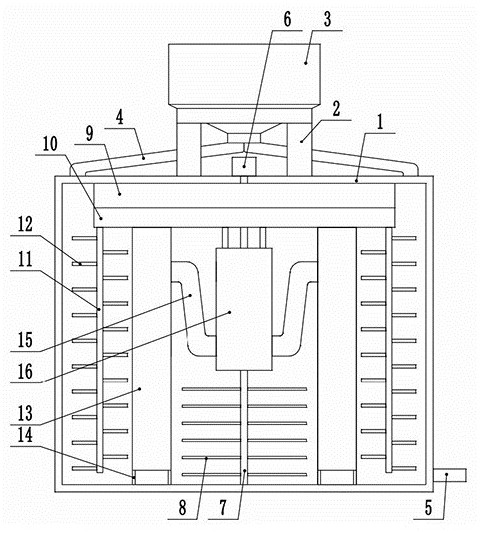

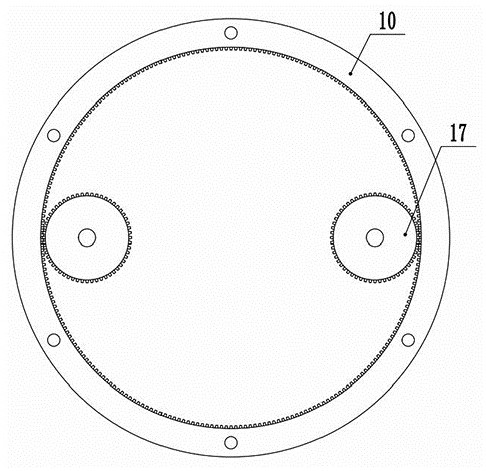

[0028] see Figure 1-8 , a turbulent wave stirring device for water-based zinc-rich paint mixing, comprising a mixing box 1, the top of the mixing box 1 is fixedly connected to the top support frame 2, the top of the top support frame 2 is fixedly connected to the feed hopper 3, the feed hopper 3 Two feeding pipes 4 are connected to the bottom of the bottom, and the two feeding pipes 4 are fixedly connected to the top two ends of the mixing box 1 respectively. The mixing box 1 is provided with a middle stirring mechanism and a side stirring mechanism, and the middle stirring mechanism and the side stirring mechanism A feeding pipe 13 is arranged between the mixing mechanisms, and the bottom support frame 14 is fixedly connected between the bottom end of the feeding pipe 13 and the bottom end in the mixing box 1, and a conveying mechanism is arranged in the feeding pipe 13, and the The top is rotatably connected to the upper rotating cover 9, and the bottom end of the upper rot...

Embodiment 2

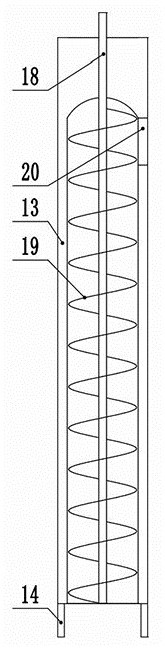

[0035] see Figure 1-8 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the screw conveyor plate 19 is provided with a plurality of installation grooves, the installation grooves run through the screw conveyor plate 19, and the filter cloth is fixedly connected in each installation groove 29 , a first discharge port 20 corresponding to the discharge pipe 15 is opened on the side of the delivery pipe 13 . The second stirring rod 12 is provided with a plurality of through holes 30, and multiple groups of crushing devices 31 are installed in each of the through holes 30. The crushing devices 31 include a fixed ring 32 fixedly arranged in the through hole 30, and the fixed ring 32 A plurality of crushing teeth 33 are fixedly connected to the inner side.

[0036]In the implementation process of the present invention, at first all kinds of raw materials that need to be mixed and prepared are put into the mixing box 1 from the feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com