Acid liquor mixing equipment

A kind of mixing equipment and equipment technology, which is applied in the direction of mixer, mining fluid, transportation and packaging, etc., can solve the problems of inability to realize instant liquid distribution, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

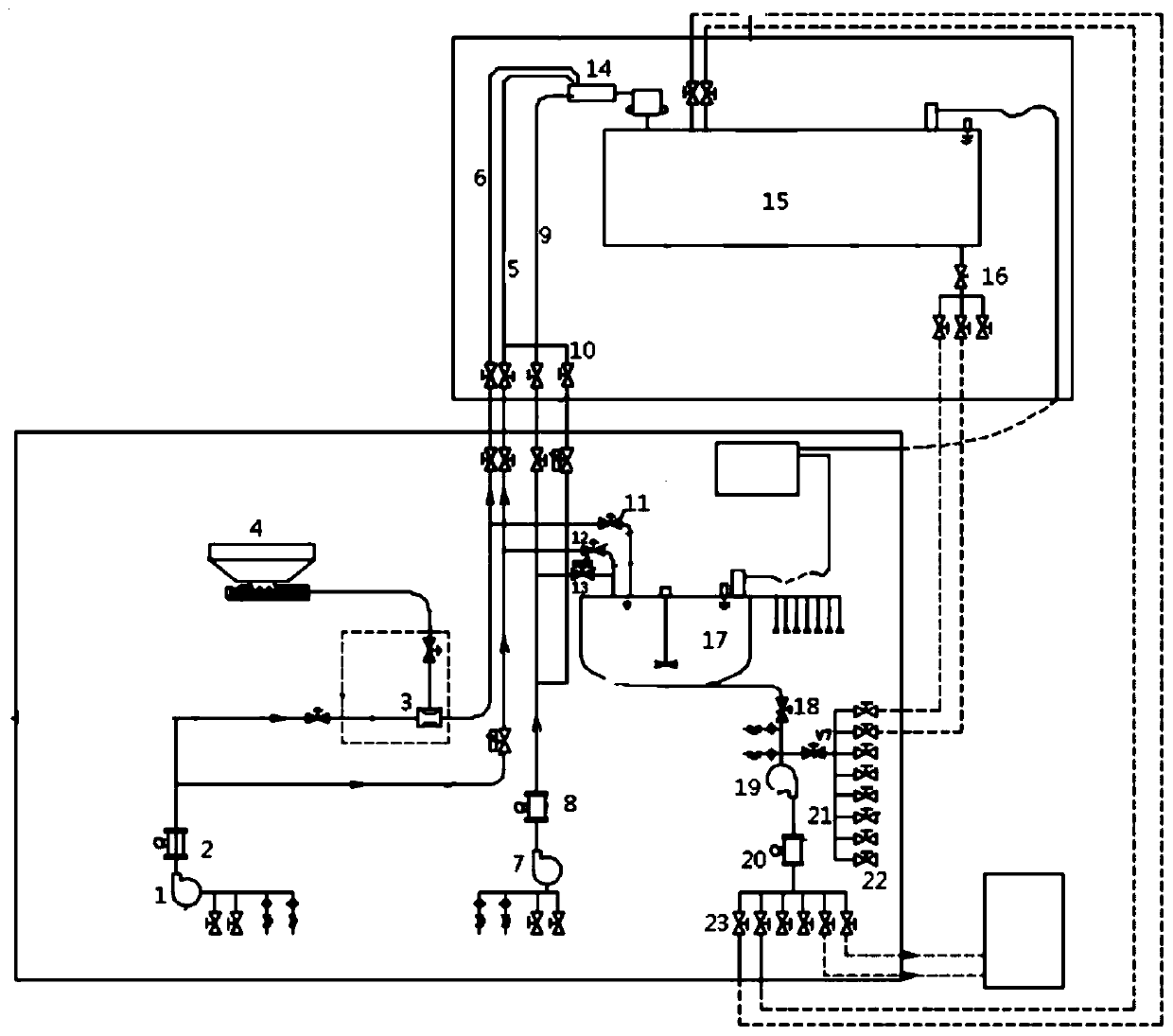

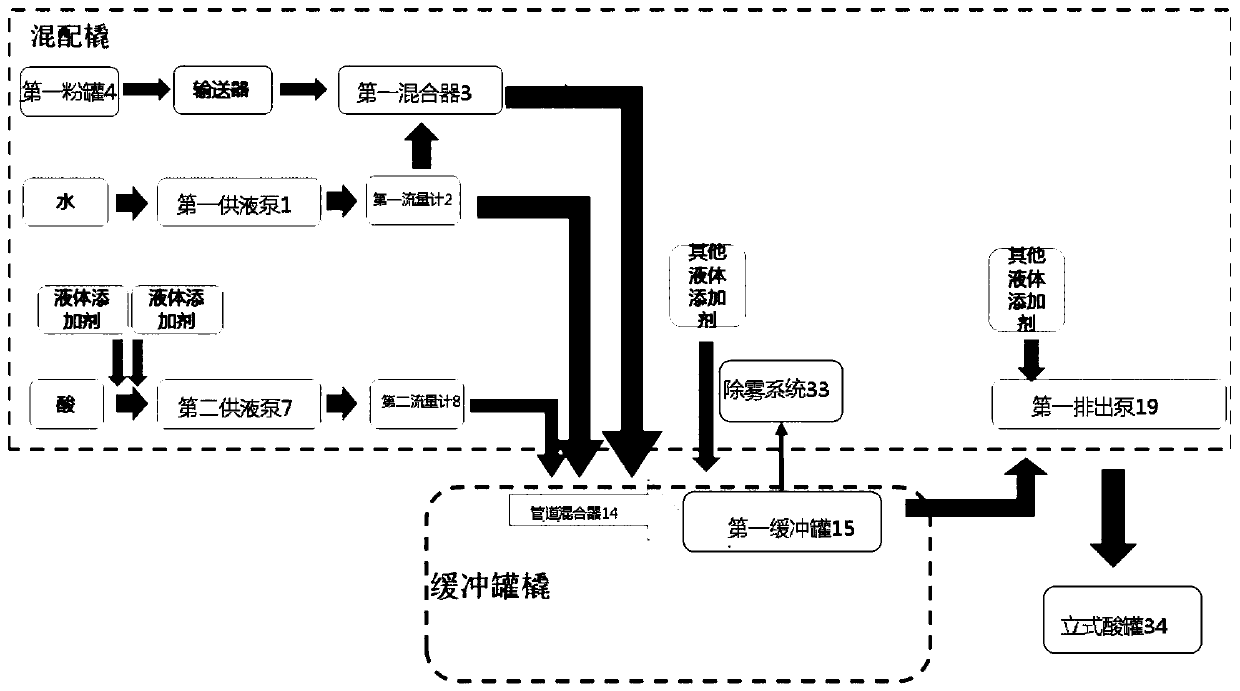

[0054] This embodiment provides a kind of gelling acid mixing equipment, the structural diagram is as follows figure 1 The equipment in this embodiment shown includes: a stirring system, a pipeline mixing system and an output system;

[0055] The stirring system in this embodiment can be the first buffer tank 15;

[0056] The pipeline mixing piping system communicates with the first buffer tank 15 for mixing materials and spraying them into the mixing system;

[0057] The first buffer tank 15 is connected with the output system, and is used for real-time output of the stirred mixed material through the output system.

[0058] The pipeline mixing system includes:

[0059] Powder mixing sub-pipeline system, acid liquid mixing sub-pipeline system and pipeline mixer 14;

[0060] The first connecting pipe 6 of the mixing sub-pipe is connected with the pipeline mixer 14;

[0061] The second connecting pipe 9 of the mixing sub-pipeline is connected with the pipeline mixer 14;

[0...

Embodiment 2

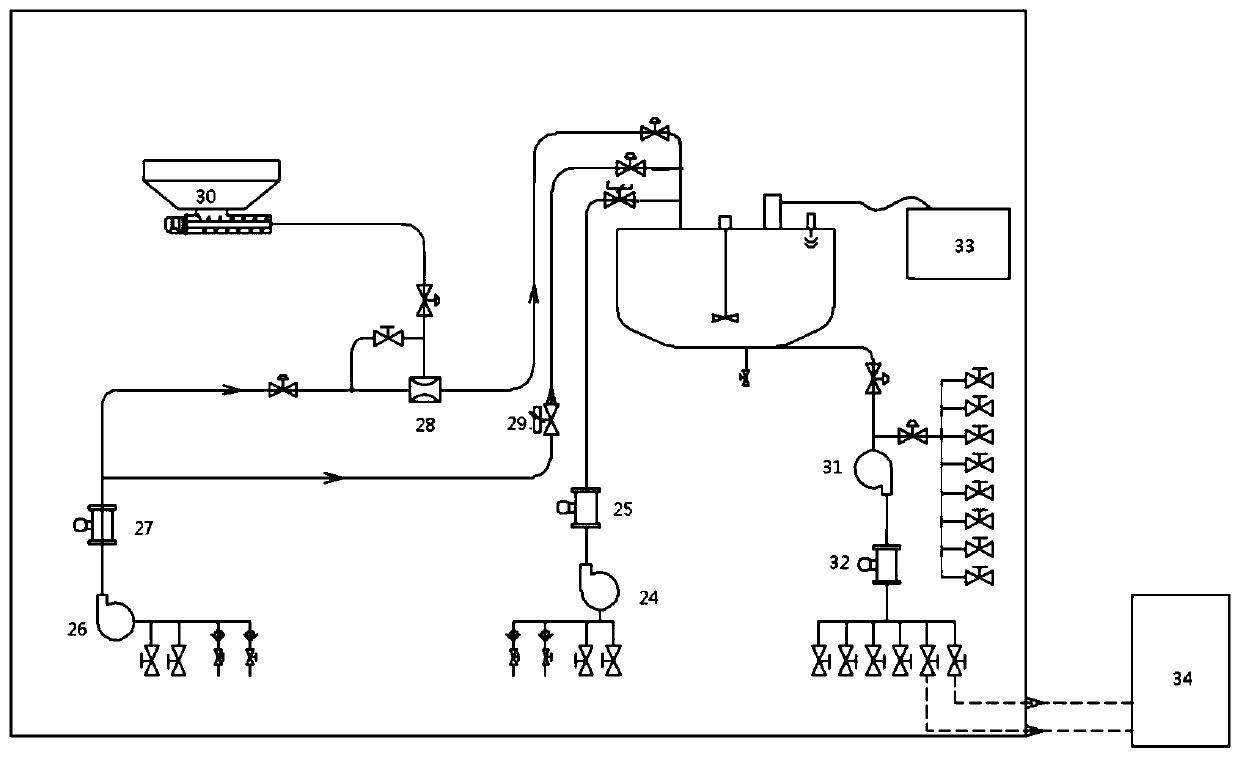

[0092] This embodiment provides a kind of general acid mixing equipment, the structural diagram is as follows figure 2 shown.

[0093] The equipment in this embodiment includes: a stirring system, a pipeline mixing piping system and an output system;

[0094] The stirring system in this implementation is a buffer tank of conventional size.

[0095] The pipeline mixing system communicates with the mixing system, and is used to mix the materials in the tube and inject them into the mixing system;

[0096] The stirring system is connected with the output system, and is used to output the stirred mixed material through the output system in real time.

[0097] The pipeline mixing piping system includes: a liquid injection sub-piping system and a mixing sub-piping system;

[0098] The liquid injection sub-pipeline system and the mixing sub-pipeline system are jointly connected with the stirring system for mixing water and acid into the stirring system through pipelines for stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com