Reaction kettle for producing benzoyl peroxide

A technology for producing benzoyl peroxide and a reaction kettle, which is applied in the field of benzoyl peroxide production equipment, can solve problems such as slow mixing efficiency, hydrogen peroxide decomposition, and temperature rise, so as to improve processing efficiency, efficient mixing reaction, and promote material recovery. The effect of exercise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

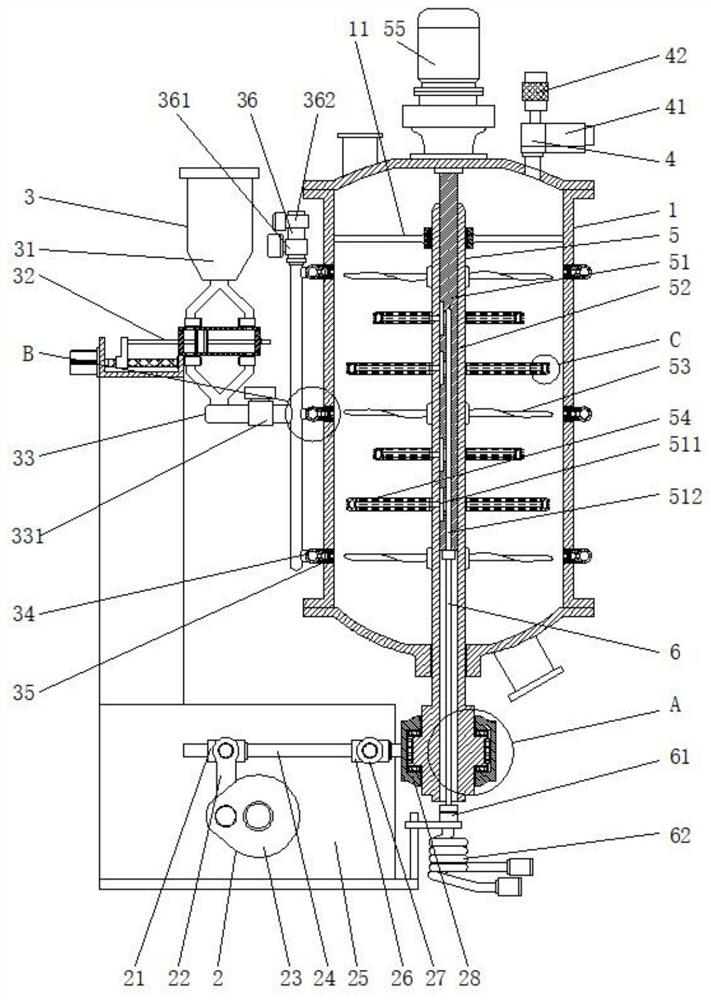

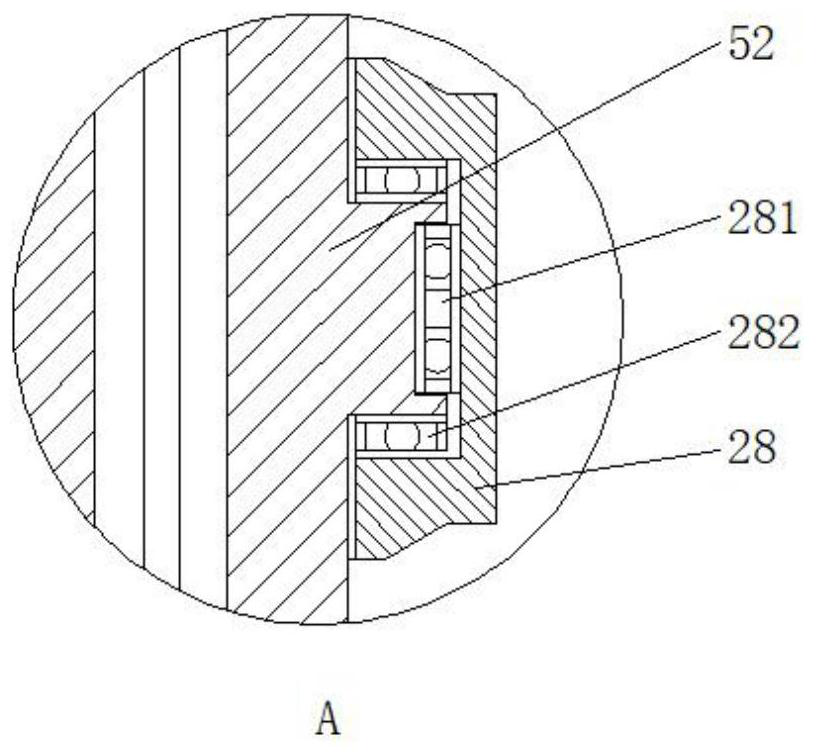

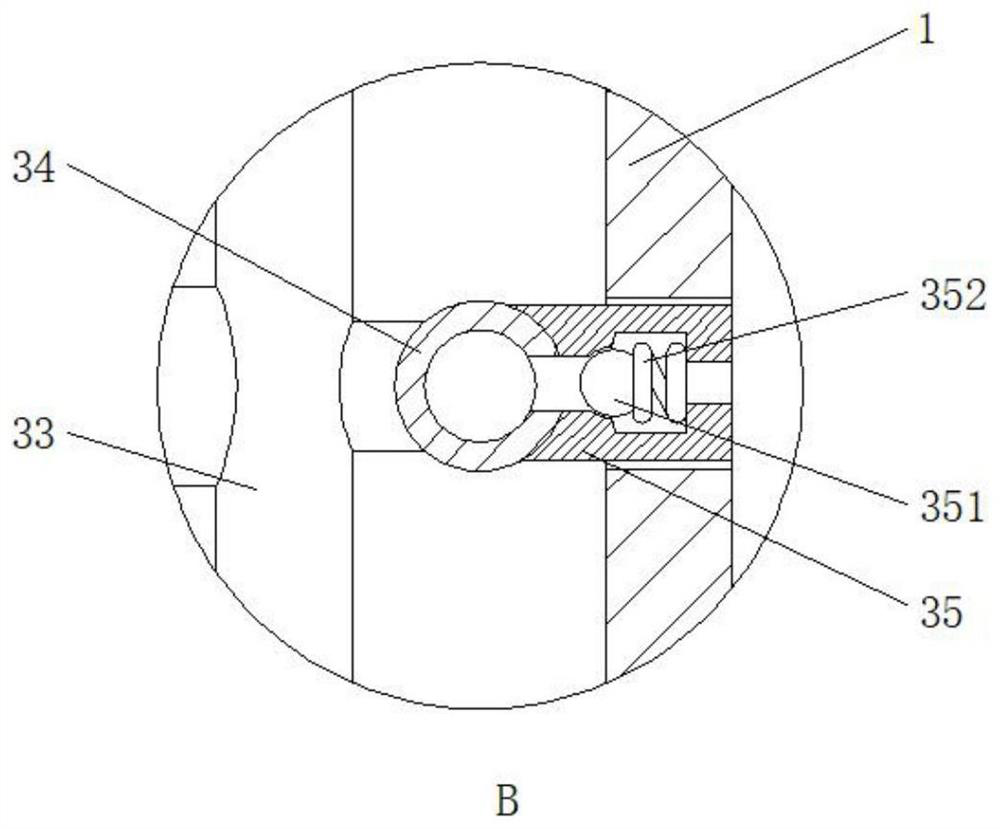

[0053] The present invention provides a kind of reactor of producing benzoyl peroxide here by improving, as Figure 1-Figure 15 Shown, a kind of reactor of producing benzoyl peroxide comprises reaction tank body 1, and agitator 5 is arranged in the middle of reaction tank body 1, and the upper end of agitator 5 is provided with main motor 55, and agitator 5 comprises central spindle 51 And the sleeve shaft 52, the sleeve shaft 52 is slidingly sleeved outside the central main shaft 51, and the outer wall of the sleeve shaft 52 is provided with a stirring blade 53 and a temperature control distribution ring 54, and the lower end of the sleeve shaft 52 passes through the lower end of the reaction tank body 1 and connects There is an up and down swinging mechanism 2; the outer wall of the reaction tank 1 is connected with a precise feeding device 3 through several injection heads 35; the top side of the reaction tank 1 is provided with a prompter 4 for the end of the reaction.

[...

Embodiment 2

[0060] The present invention provides a kind of reactor of producing benzoyl peroxide here by improving, as Figure 1-Figure 15 Shown, a kind of reactor of producing benzoyl peroxide comprises reaction tank body 1, and agitator 5 is arranged in the middle of reaction tank body 1, and the upper end of agitator 5 is provided with main motor 55, and agitator 5 comprises central spindle 51 And the sleeve shaft 52, the sleeve shaft 52 is slidingly sleeved outside the central main shaft 51, and the outer wall of the sleeve shaft 52 is provided with a stirring blade 53 and a temperature control distribution ring 54, and the lower end of the sleeve shaft 52 passes through the lower end of the reaction tank body 1 and connects There is an up and down swinging mechanism 2; the outer wall of the reaction tank 1 is connected with a precise feeding device 3 through several injection heads 35; the top side of the reaction tank 1 is provided with a prompter 4 for the end of the reaction.

[...

Embodiment 3

[0069] The present invention provides a kind of reactor of producing benzoyl peroxide here by improving, as Figure 1-Figure 15 Shown, a kind of reactor of producing benzoyl peroxide comprises reaction tank body 1, and agitator 5 is arranged in the middle of reaction tank body 1, and the upper end of agitator 5 is provided with main motor 55, and agitator 5 comprises central spindle 51 And the sleeve shaft 52, the sleeve shaft 52 is slidingly sleeved outside the central main shaft 51, and the outer wall of the sleeve shaft 52 is provided with a stirring blade 53 and a temperature control distribution ring 54, and the lower end of the sleeve shaft 52 passes through the lower end of the reaction tank body 1 and connects There is an up and down swinging mechanism 2; the outer wall of the reaction tank 1 is connected with a precise feeding device 3 through several injection heads 35; the top side of the reaction tank 1 is provided with a prompter 4 for the end of the reaction.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com