Protein separation and extraction device

A protein separation and extraction device technology, applied in the field of protein separation and extraction devices, can solve problems such as low separation efficiency and high viscosity, and achieve the effects of promoting separation and extraction, promoting material movement, and facilitating separation of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

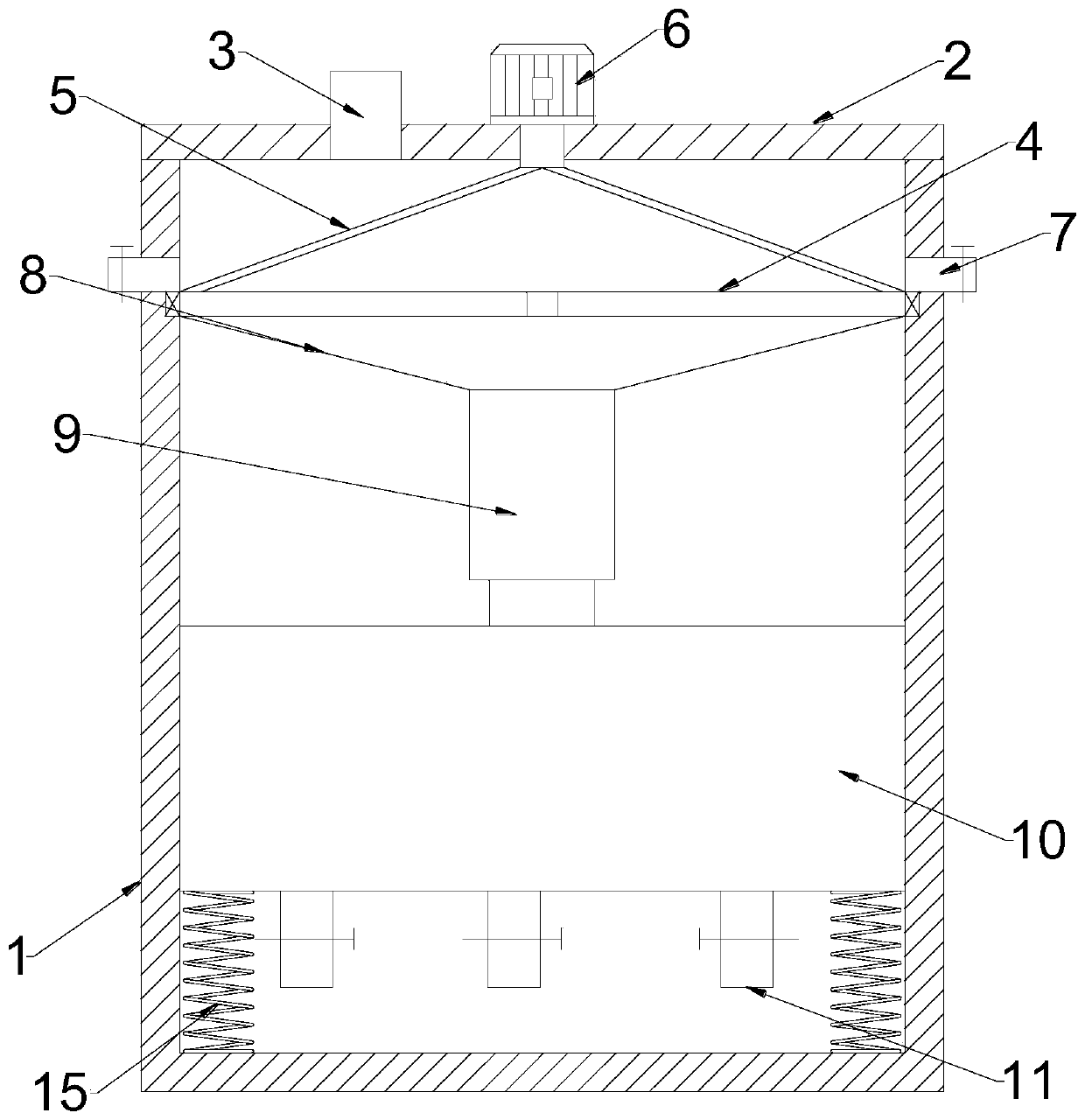

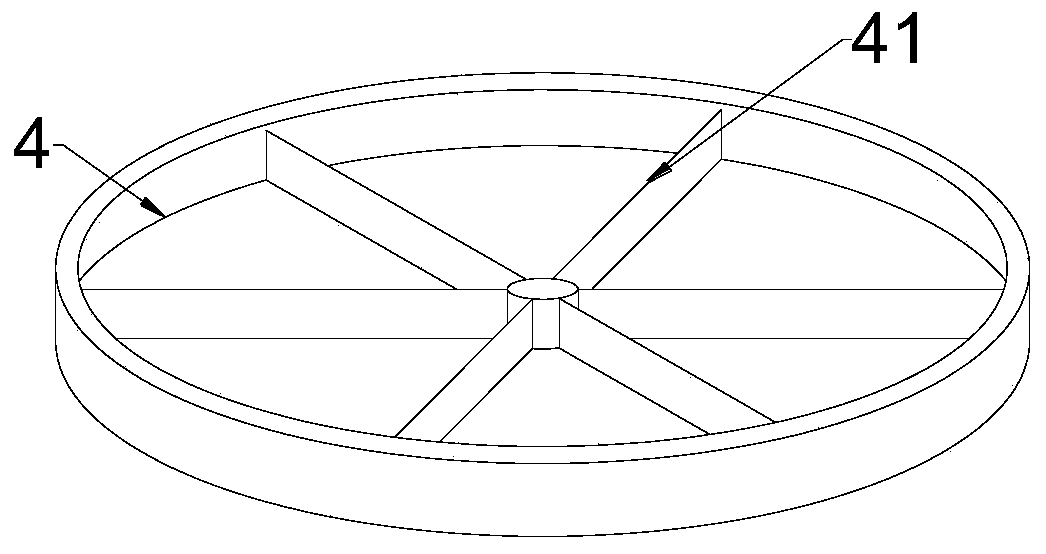

[0028] see Figure 1~4 , in an embodiment of the present invention, a protein separation and extraction device includes a housing 1, an impurity removal mechanism for removing material impurities and a separation structure 10 for extracting and separating proteins, and the lower end of the impurity removal mechanism passes through a flow guide cover 8 It communicates with the material guide pipe 9 and the separation structure 10. The impurity removal mechanism is connected in the housing 1 through rotation. The impurity removal mechanism is also connected with a rotating ring 4, and a fan blade 41 is connected inside the rotating ring 4.

[0029] The upper end of the housing 1 is assembled and connected with an upper cover 2, and the upper cover 2 is fixed on the upper end of the housing 1 by riveting; the upper cover 2 is provided with a feed pipe 3 and a first motor that drives the impurity removal mechanism to rotate 6.

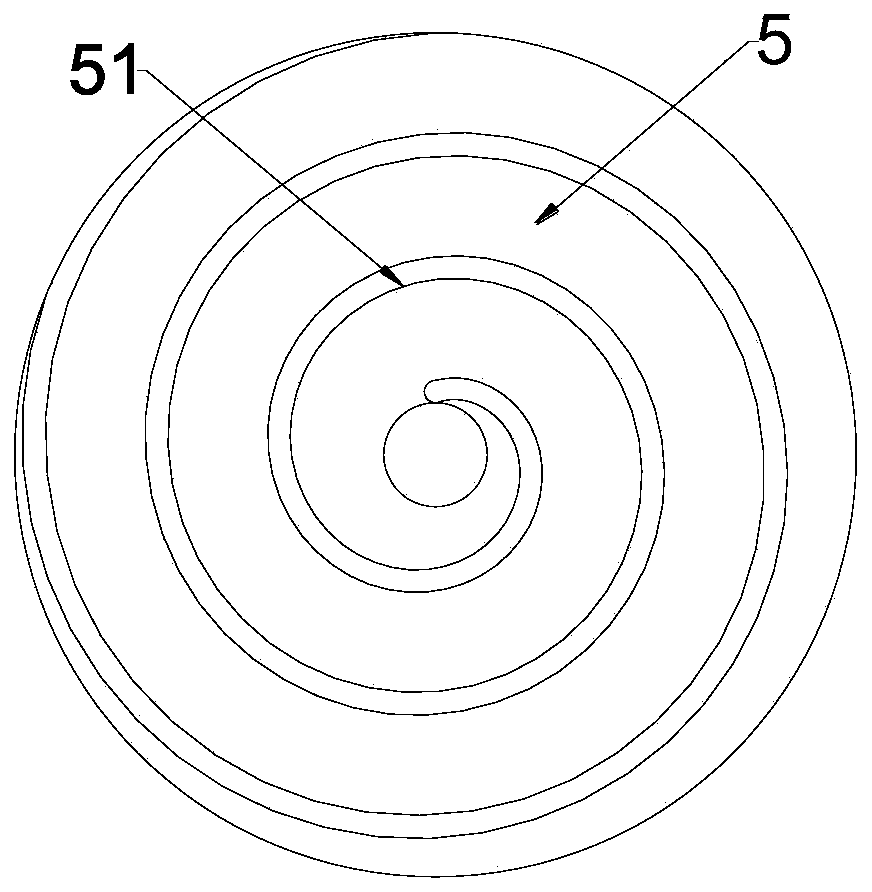

[0030] The impurity removal mechanism includes a fi...

Embodiment 2

[0034] see Figure 5-6 , in the embodiment of the present invention, a protein separation and extraction device, because the viscosity of the protein material is relatively high, if the separation and extraction only rely on gravity, the efficiency is too low, so on the basis of Example 1, the separation structure 10 The upper end is welded with a lifting frame 12, and a through slot is provided through the lifting frame 12, and racks are embedded symmetrically on both sides of the through slot; the inner wall of the housing 1 is also connected with a second motor 13, and the first The periphery of the output end of the second motor 13 is fixedly connected with an incomplete gear 14, and the incomplete gear 14 is located between the racks in the lifting frame 12, and the incomplete gear 14 meshes with the racks on both sides respectively. Transmission, the incomplete gear 14 is a half gear. Start the second motor 13 to drive the incomplete gear 14 to rotate, and the incomplet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com