Grouting equipment for constructing impervious curtain of dam

A technology of anti-seepage curtains and dams, which is applied in the field of dam grouting, which can solve the problems of low construction efficiency of water-blocking curtains and difficult driving of concrete mixer trucks, and achieve the effects of avoiding dust, improving construction efficiency, and avoiding difficult driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

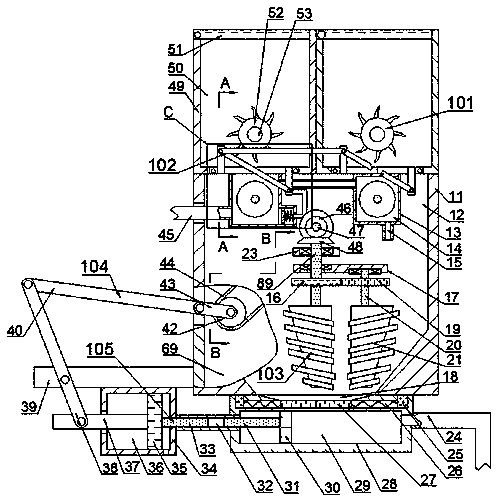

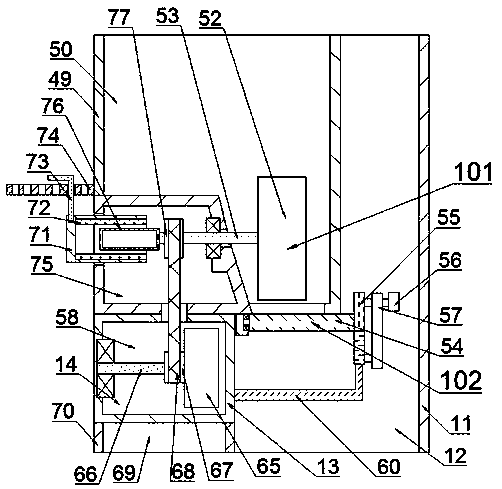

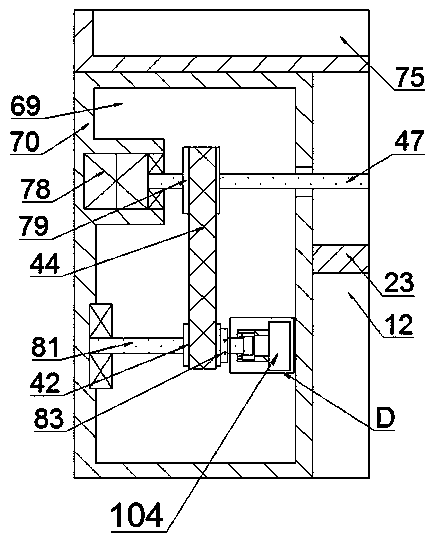

[0019] Combine below Figure 1 to Figure 5 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are consistent.

[0020] The present invention relates to a kind of grouting equipment that is used for the construction of anti-seepage curtain of embankments, and is mainly used in embankment grouting. The present invention will be further described below in conjunction with the accompanying drawings of the present invention:

[0021]A kind of grouting equipment used for the construction of embankment anti-seepage curtain according to the present invention comprises a mixing box 11, the mixing box 11 is provided with a mixing chamber 12 with an opening facing downward, and a quantitative device 101 is provided in the mixing chamber 12 The dosing device 101 can be arranged through two storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com