Anti-dismantle tee operated without switching off air source

An anti-demolition and air-filled technology, which is applied in the tee field, can solve problems such as insufficient fluid pressure and affect the use of users, and achieve the effect of increasing flow and ensuring air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

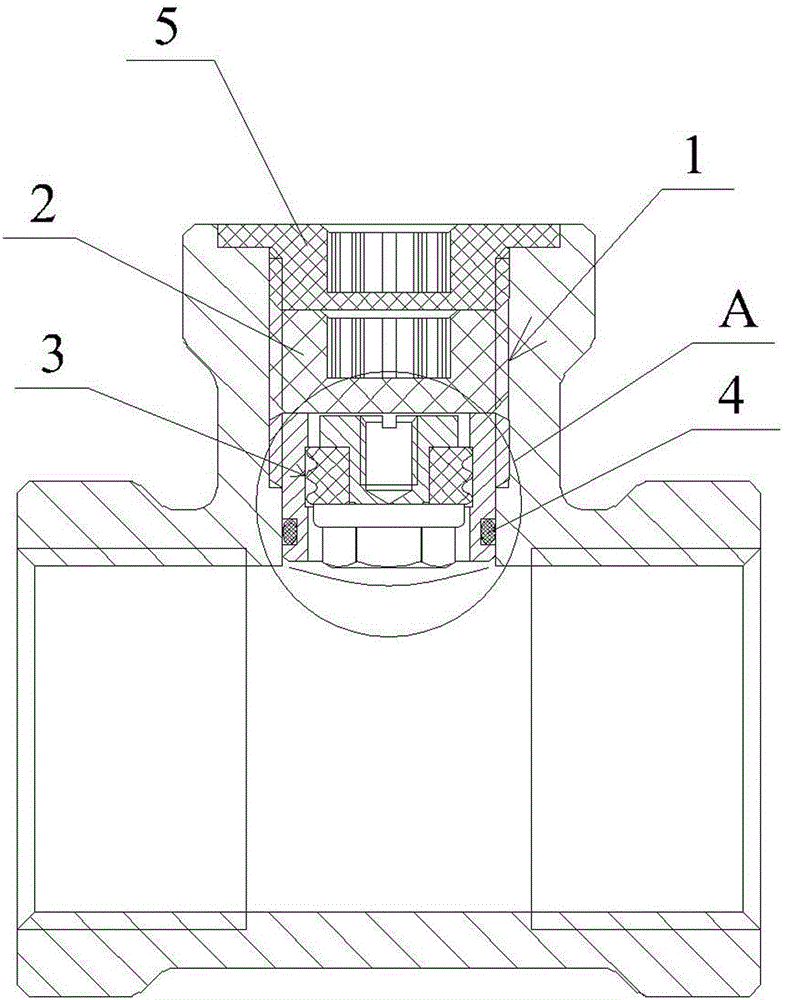

[0021] see Figure 1 to Figure 3 As shown, the air-operated anti-dismantle tee of the present invention includes a first channel 1, a second channel and a third channel that communicate with each other; the first channel 1 is provided with a plug 2 with an anti-dismantle sink hole , the inner port of the first channel 1 is provided with a seal 3;

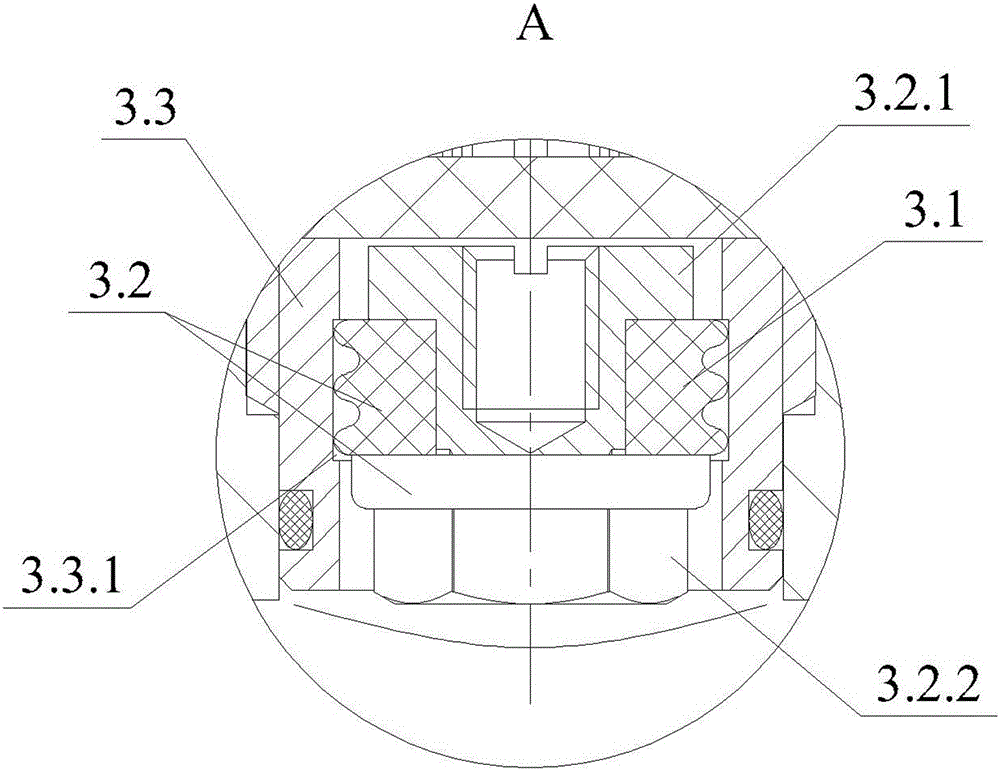

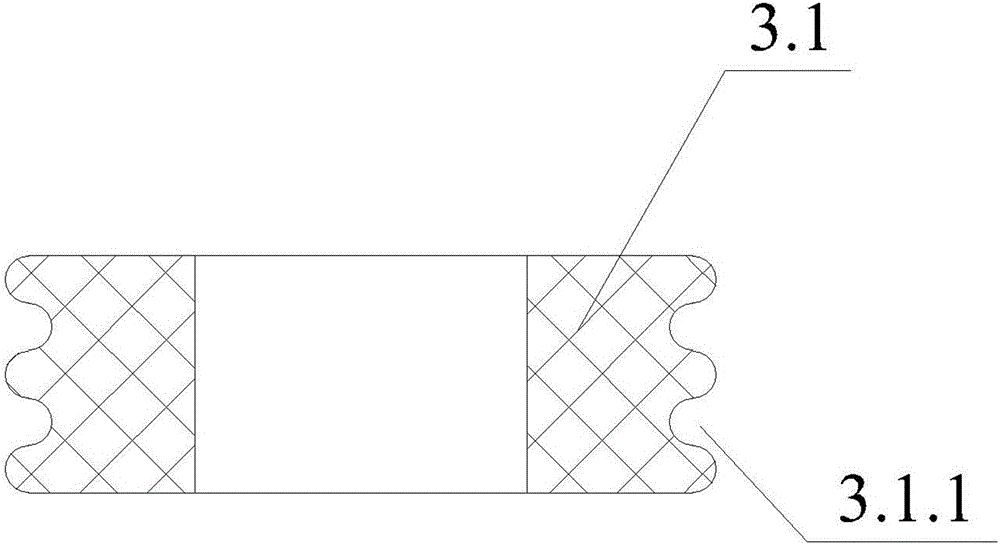

[0022] The sealing member 3 includes a sealing ring 3.1 made of elastic material and a connecting piece 3.2 for connecting with the opening tool; the sealing ring 3.1 is installed in the first channel 1 axially in a limited manner In the port, at least one radial annular groove 3.1.1 is provided on the outer wall of the sealing ring 3.1; the connecting piece 3.2 is connected to the middle of the sealing ring 3.1.

[0023] The seal 3 also includes a hollow press nut 3.3; the inner side wall of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com