Pipe flow type inner wall erosion corrosion test device

A technology for scouring corrosion and testing devices, used in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problem of high construction cost, improve the uniformity of the medium, improve the stirring efficiency, and facilitate the discharge and cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The structure and working process of the present invention will be further described in detail below in conjunction with the accompanying drawings.

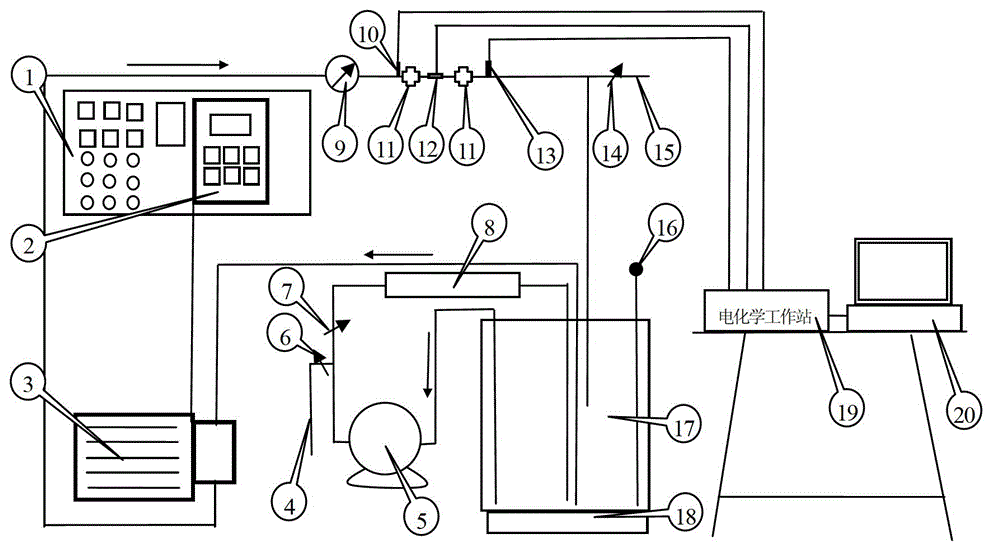

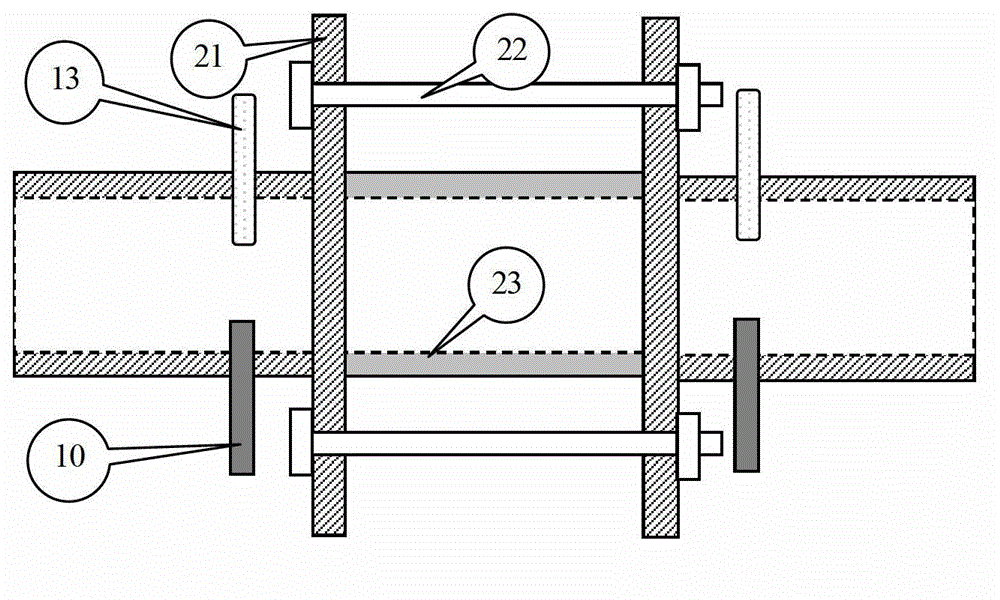

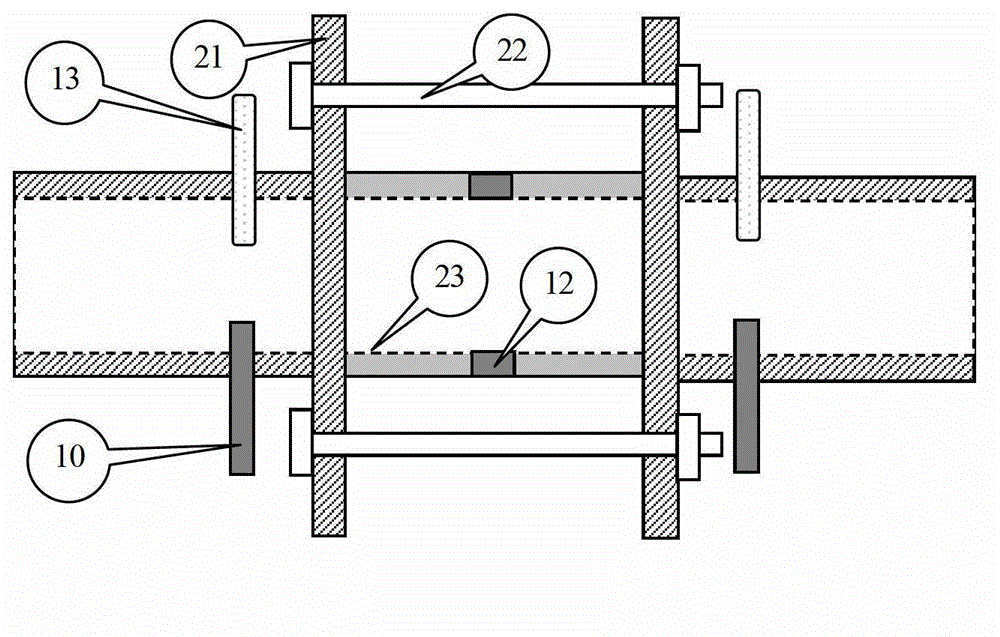

[0028] Such as figure 1 As shown, the pipe flow type inner wall erosion corrosion test device of the present invention mainly includes: control cabinet 1, frequency converter 2, power pump 3, discharge pipe I4, stirring pump 5, ball valve I6, ball valve II7, cooler 8, electromagnetic flow Gauge 9, auxiliary electrode 10, special fixture 11, sample to be tested 12, reference electrode 13, ball valve III14, discharge pipe II 15, thermocouple 16, slurry tank 17, heater 18, electrochemical workstation 19, control The specific structure is as follows:

[0029] The slurry tank 17 is respectively connected to the power pump 3 and the stirring pump 5 through pipelines. The input end of the power pump 3 is directly connected to the slurry tank 17 through pipelines, and the output end of the power pump 3 is connected to the slurry tank 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com