Fertilizer slurry stirring and emulsifying device

An emulsification device and slurry technology, applied in mixer accessories, transportation and packaging, chemical instruments and methods, etc., can solve the problem of inability to drive the vertical movement of materials, and achieve the effect of being beneficial to emulsification and enhancing mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

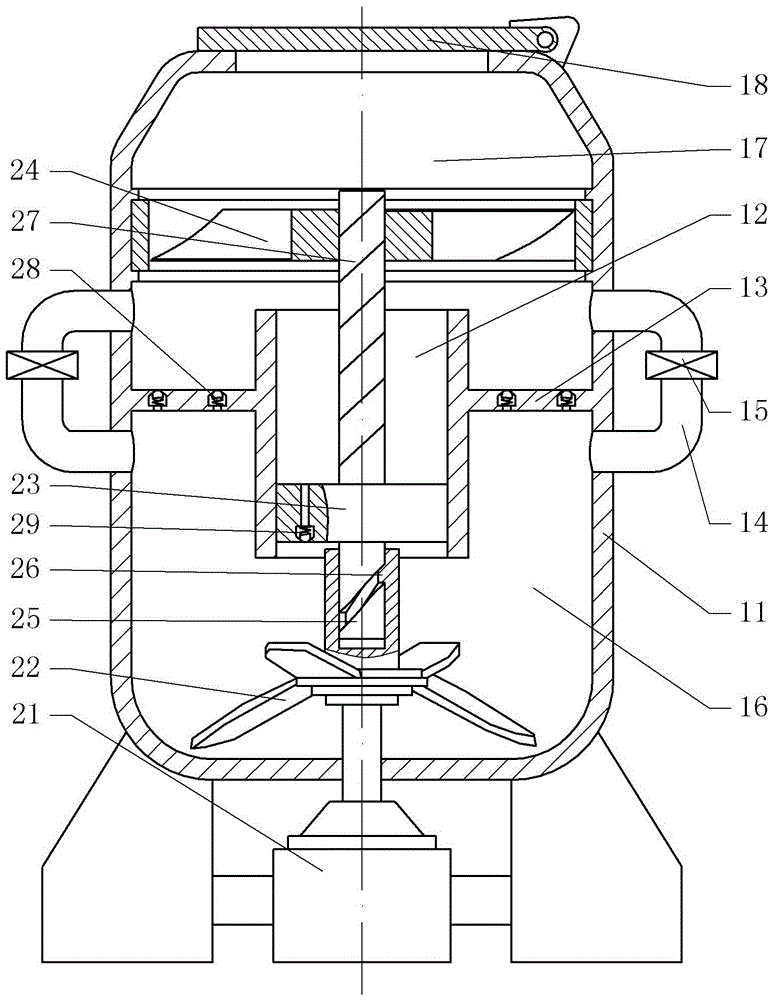

[0017] The reference signs in the drawings of the description include: outer cylinder 11, inner cylinder 12, partition 13, communication pipe 14, communication valve 15, stirring chamber 16, injection chamber 17, sealing cover 18, driving motor 21, stirring blade 22, Piston 23, disturbance vane 24, cylindrical cam 25, linkage block 26, screw rod 27, first one-way valve 28, second one-way valve 29.

[0018] The embodiment is basically as figure 1 Shown:

[0019] The chemical fertilizer slurry stirring and emulsifying device of the present embodiment comprises a base, an emulsifying cylinder and a stirring device; the emulsifying cylinder is welded on the base, and the emulsifying cylinder comprises an outer cylinder 11 and an inner cylinder 12, and the middle part of the outer cylinder 11 is provided with a partition 13, and the partition The upper part of the plate 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com