Carbon compensator for large-scale culturing micro-algae, its utilization and use

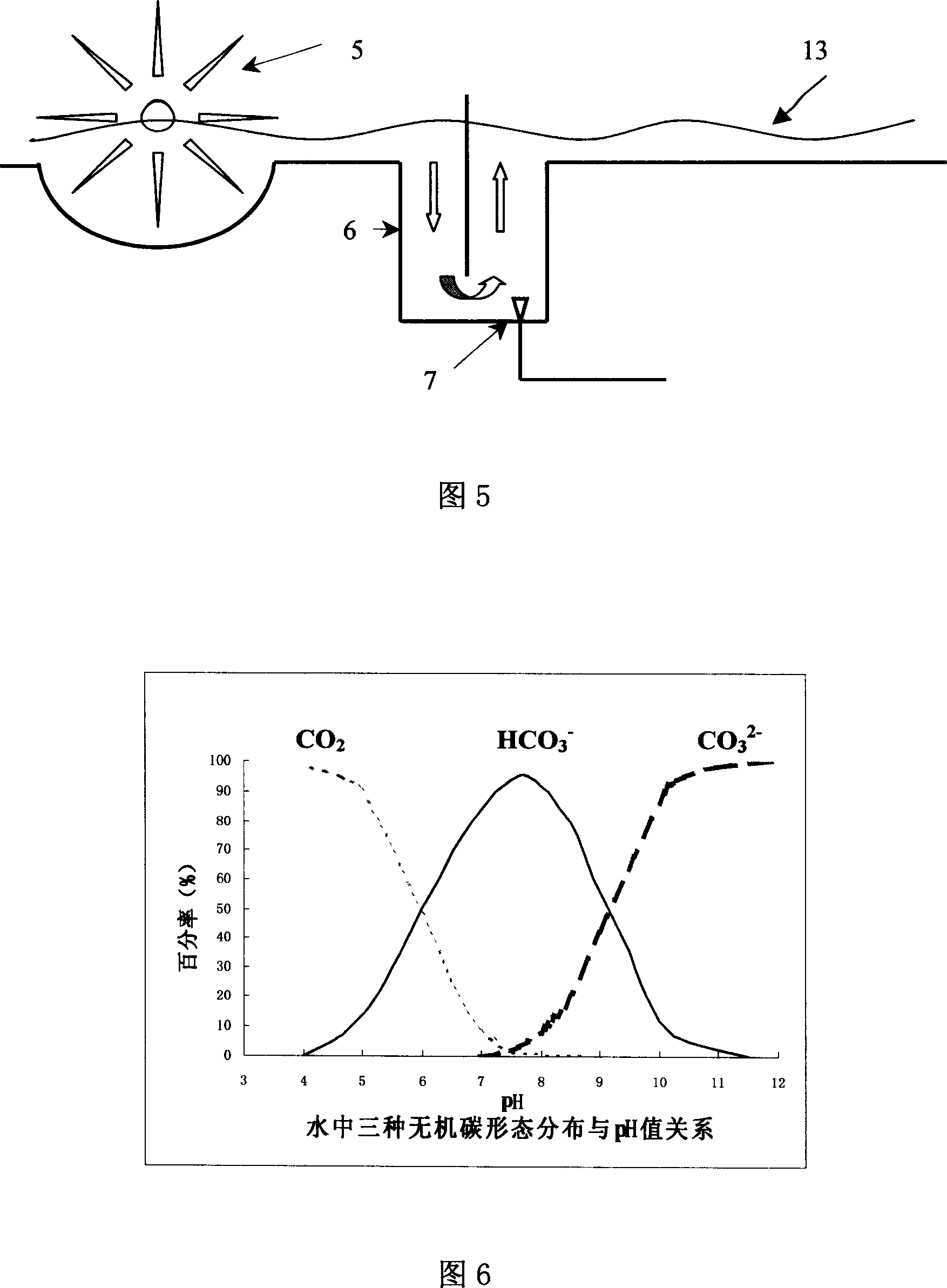

A large-scale cultivation and carbon replenishment technology, which is applied in enzymology/microbiology devices, biochemical cleaning devices, biochemical equipment and methods, etc., can solve the waste of carbon sources, the inability to be used, the waste of water resources and carbon sources, etc. problems, to achieve the effect of prolonging the gas-liquid contact time, reducing production costs and improving absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

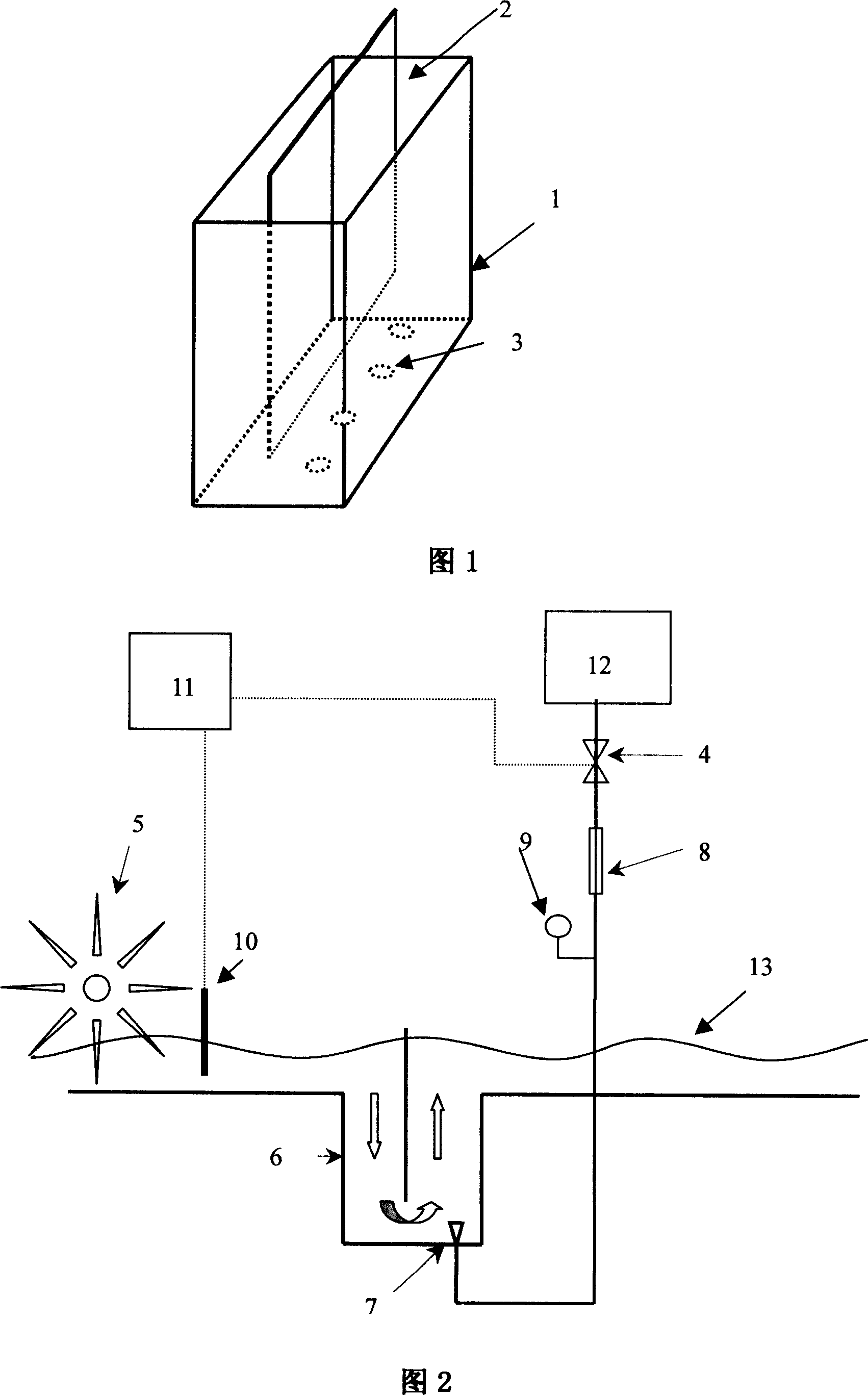

[0047] Spirulina culture is carried out in the raceway culture tank. The runway pool has a circumference of 200 meters, a width of 2 meters and a water depth of 15 centimeters. The driving device of the culture medium is a steel impeller driven by a motor. The algal species were from the Institute of Process Engineering, Chinese Academy of Sciences, the species was Spirulina Platensis, the medium was Zarrouk medium, and the initial concentration of sodium bicarbonate in the culture medium was 0.1mol / L.

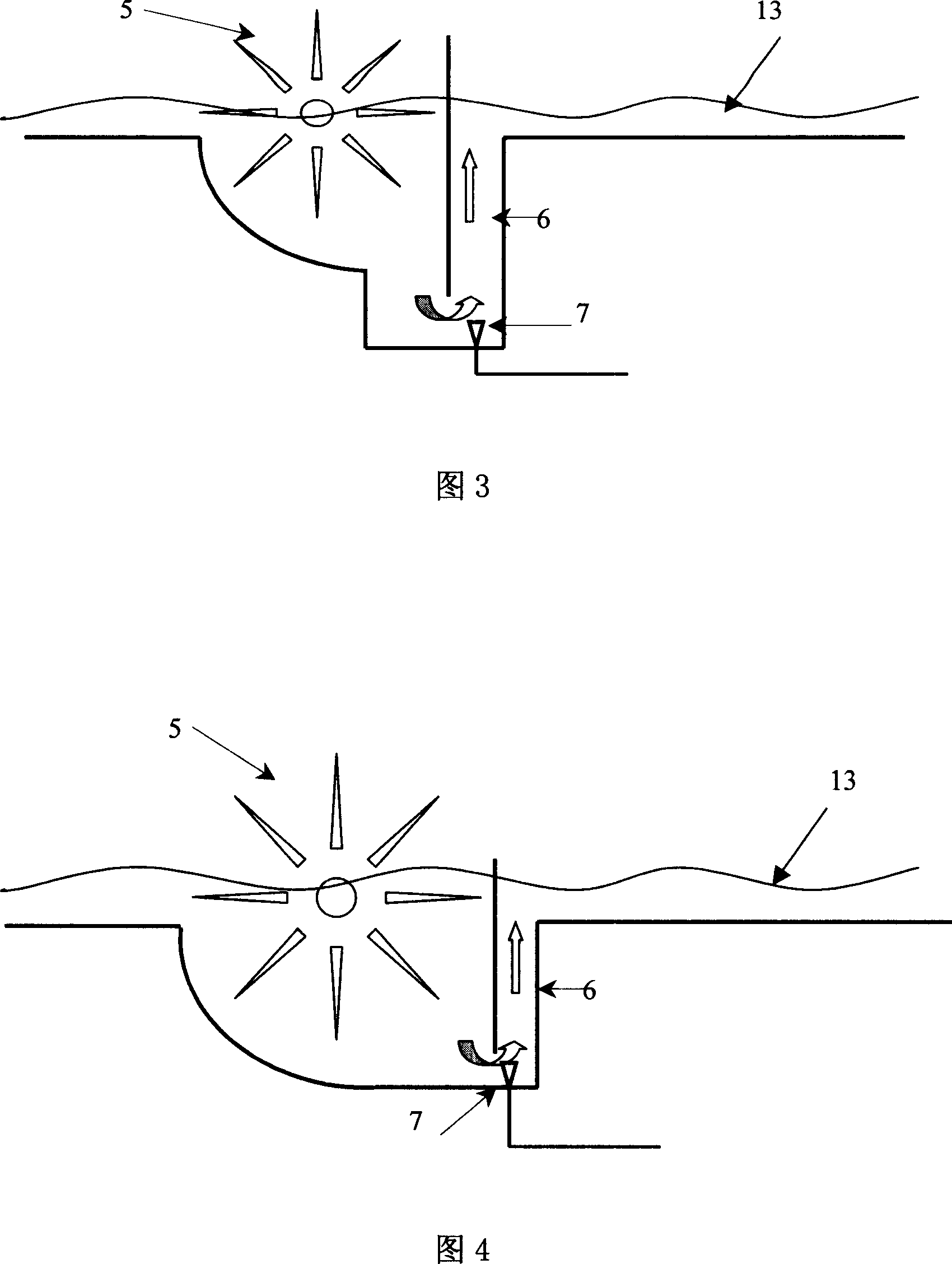

[0048] Automatic carbon replenishment is adopted, the automatic control method is shown in CN200410009360.4, and the implementation scheme system is shown in Figure 2. Wherein, the pH sensor 10 is a commercially available steam sterilizable pH electrode, the control device 11 is a pH meter with switch control, CO 2 The gas source 12 is pure carbon dioxide gas, the actuator 4 is a two-position normally closed solenoid valve (diameter 8 mm), and the gas distributor 7 is a glas...

Embodiment 2

[0050] With embodiment 1, but the initial concentration of sodium bicarbonate is changed into 0.2mol / L, and the flow rate (executive agency 4 is opened) of carbon dioxide gas in each trap type container is 4.0L / min (standard condition). Continuously cultivated for 2 months, the yield of algae per unit area reaches 9.5g / m 2 .d. The composition and content of conventional components, amino acids, fatty acids and carotenoids obtained from Spirulina algae powder are basically consistent with those reported in the literature. Each kilogram of algal powder (dry weight) consumes about 2.62 kilograms of carbon dioxide.

Embodiment 3

[0052] Same as Example 1, the difference is that the pH control range is 8.5-11.0, and the flow rate of carbon dioxide gas in each well-type container (4 open actuators) is 4.0 L / min (standard condition). Continuously cultivated for 2 months, the yield of algae per unit area reaches 9.0g / m 2 .d. The composition and content of conventional components, amino acids, fatty acids and carotenoids obtained from Spirulina algae powder are basically consistent with those reported in the literature. Each kilogram of algal powder (dry weight) consumes about 2.5 kilograms of carbon dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com