Horizontal reciprocated type agitating equipment of straw powder dust wastes

A technology of waste and straw, which is applied in the field of batching mixing and fermentation mixing in the resource utilization production of horticultural straw crushed substrate, which can solve the problems of incomplete and uneven mixing, high use cost, and large power consumption, and achieve high application and promotion Value, good working environment, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

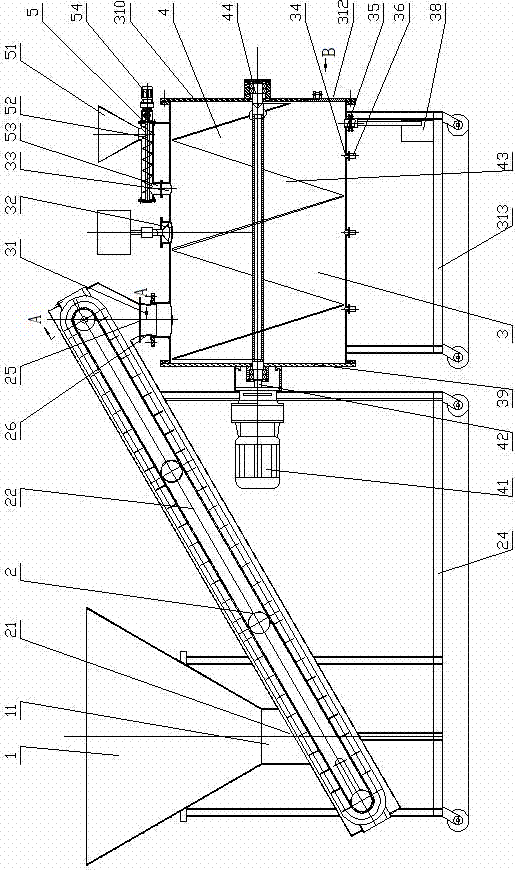

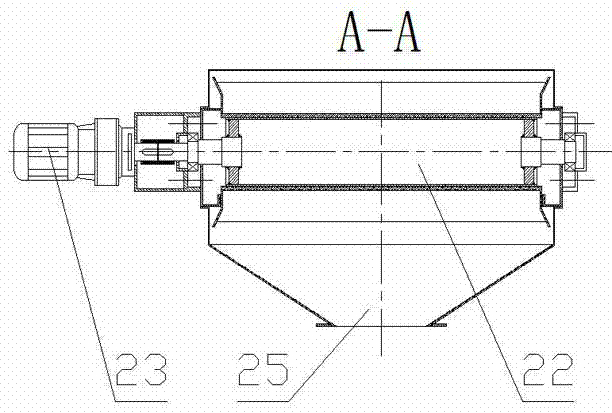

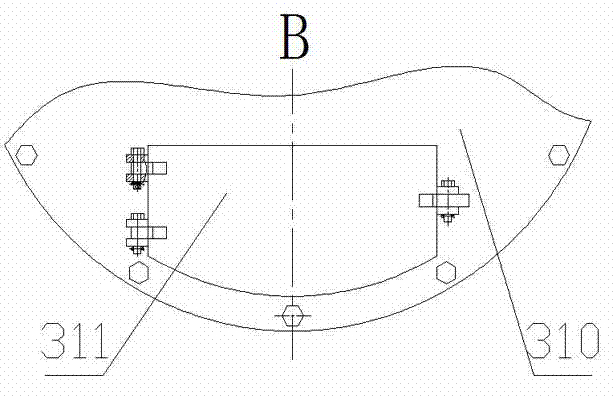

[0020] Such as figure 1 , 2 , 3, and 4, the horizontal reciprocating mixing equipment for straw scraps and wastes of the present invention includes a feed bin 1, a belt feeder 2, a stirring working bin 3, a spiral stirring device 4, an auxiliary feeder 5 and a humidifier 6 and so on. The positional relationship of each component is: silo 1 is located above the belt feeder 2, and the belt feeder 2 is between the silo 1 and the mixing chamber 3. Port 31 is connected; in addition to the main feeding port 31, an auxiliary feeding port 33 and a humidifying port 32 are provided on the top of the stirring work chamber 3. The stirring work chamber 3 is connected with the auxiliary feeder 5 through the auxiliary feeding port 33, and the stirring work chamber 3 is connected to the humidifier 6 through the humidifying port 32; the stirring working compartment 3 includes a left compartment cover 39, a right compartment cover 310 and a horizontal spiral stirring device 4, and the left co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com