Plant micro powder suspension strengthening and stabilizing machine

A technology for stabilizing machine and micropowder, applied in mixers, mixer accessories, cleaning hollow objects, etc., can solve problems such as the inability to meet the requirements of plant micropowder suspension strengthening and stability, increasing the precipitation of plant micropowder suspension, and contamination, etc., to reduce The probability of sedimentation, the effect of improving stirring efficiency and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

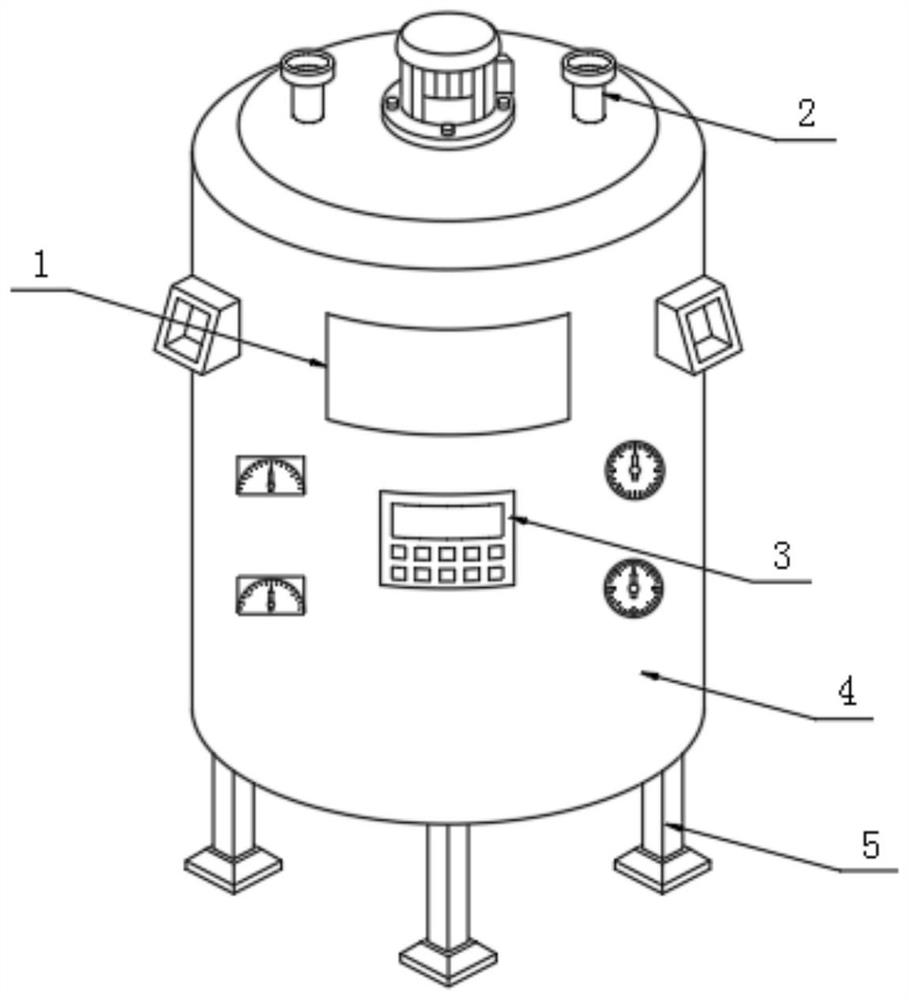

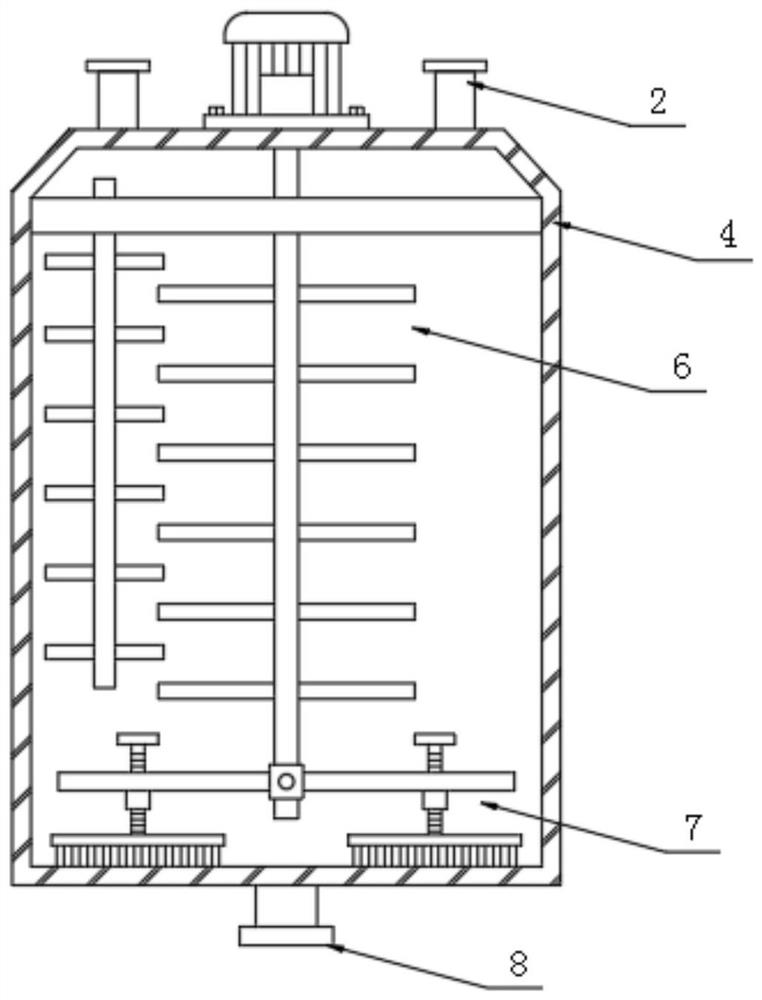

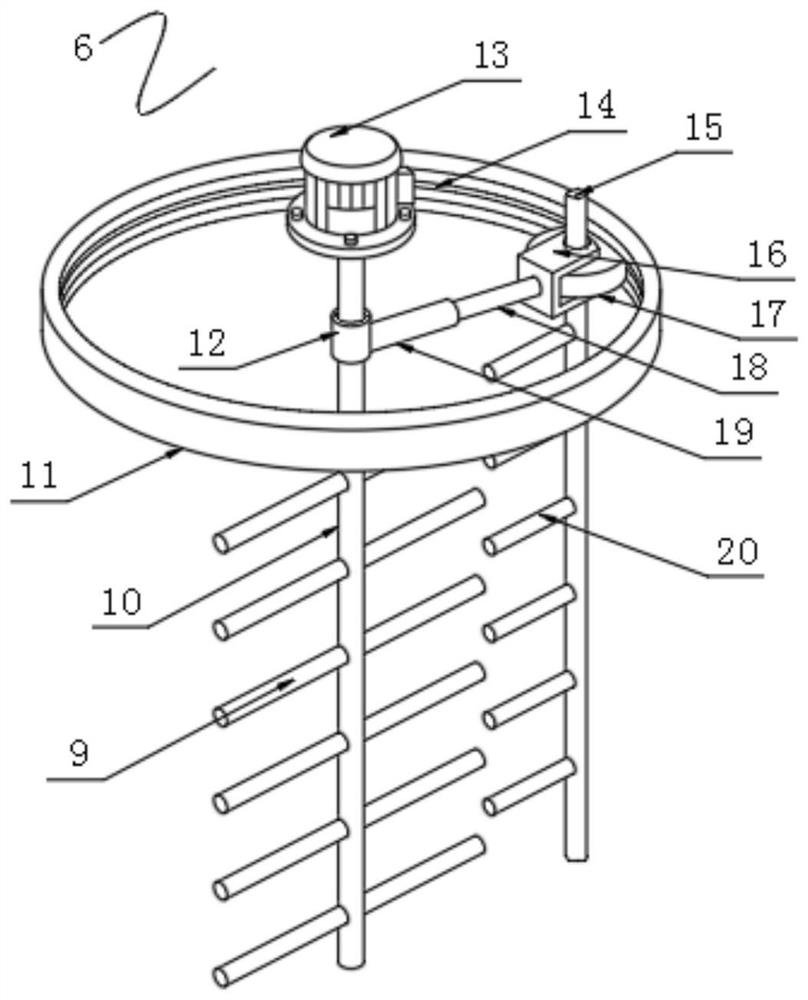

[0020] see Figure 1~5 , in an embodiment of the present invention, a plant micropowder suspension strengthening and stabilizing machine includes a body 4, a controller 3 fixed on the front surface of the body 4, an observation window 1 embedded and installed on the front surface of the body 4, and a solid connection on the body 4. 4 The injection port 2 at the edge of both sides of the upper surface and the discharge port 8 fixed at the center of the lower surface of the body 4, the four corners of the lower surface of the body 4 are fixed with support legs 5, the model of the controller 3 It is DKC-Y110, and a drive device 6 is installed inside the body 4. The drive device 6 includes a first stirring rod 9, a first rotating shaft 10, a fastening ring 11, a limit ring 12, a motor 13, a limit groove 14, a first Two rotating shafts 15, mounting frame 16, roller 17, bracket 18, support rod 19 and second stirring rod 20, motor 13 is fixedly connected at the center of the upper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com