Energy-saving treatment system for preparing gypsum cementing material from industrial byproduct gypsum

A technology for industrial by-products of gypsum and cementitious materials, applied in the field of energy-saving treatment systems, can solve the problems of inability to realize heat recycling, heat loss to the environment, low efficiency, etc., to avoid adverse effects, protect internal structures, and improve heat exchange efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

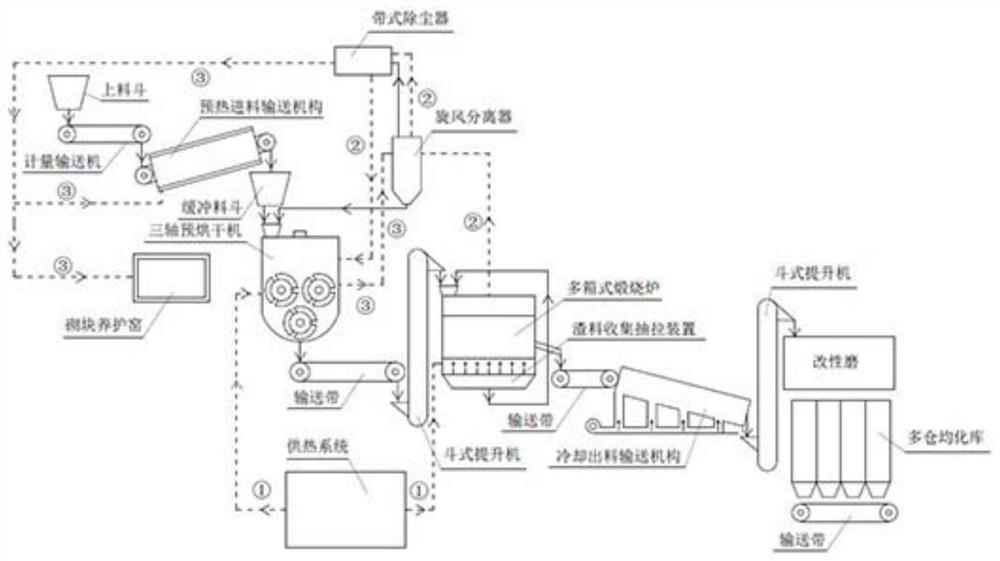

[0028] In order to make the objectives, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions will be clearly and completely described below in conjunction with the drawings and embodiments of the present invention. Describe the scheme of the present invention in detail below in conjunction with specific embodiment:

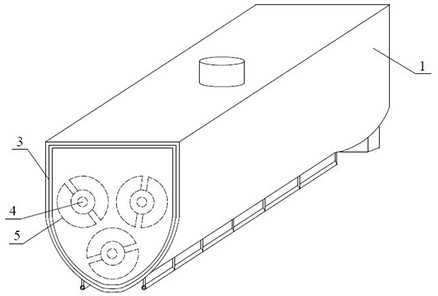

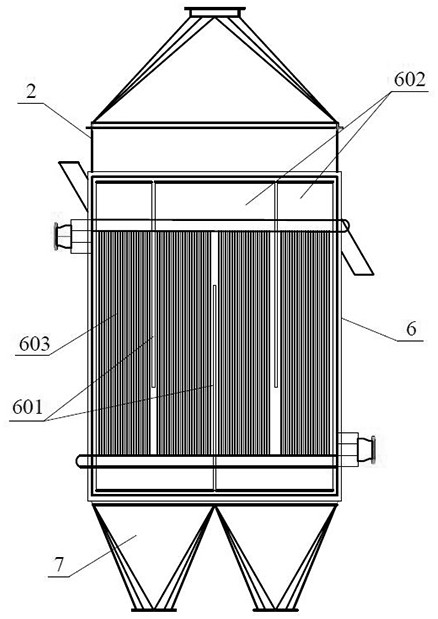

[0029] As an embodiment of the present invention, as shown in the accompanying drawings, the energy-saving treatment system for preparing gypsum cementitious materials from industrial by-product gypsum achieves energy saving while realizing resource utilization of industrial by-product gypsum, and greatly improves fuel efficiency. Utilization rate, and avoiding the adverse impact on the environment caused by the direct discharge of hot air, the energy-saving treatment system includes:

[0030] The raw material system is used to provide industrial by-product gypsum and transport it to the processing product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com